Ultraviolet-cured bio-based pressure-sensitive adhesive, pressure-sensitive adhesive tape and preparation method thereof

An ultraviolet light and bio-based technology, applied in the field of pressure-sensitive adhesives, can solve the problems of inferiority, poor physical properties of pressure-sensitive adhesives, and unusability, and achieve the effects of reducing consumption, reducing carbon emissions, and reducing the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

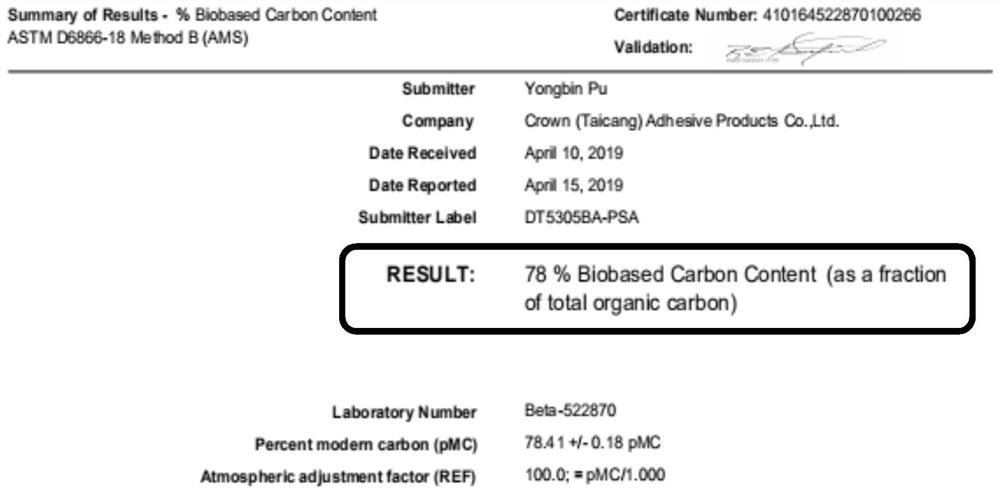

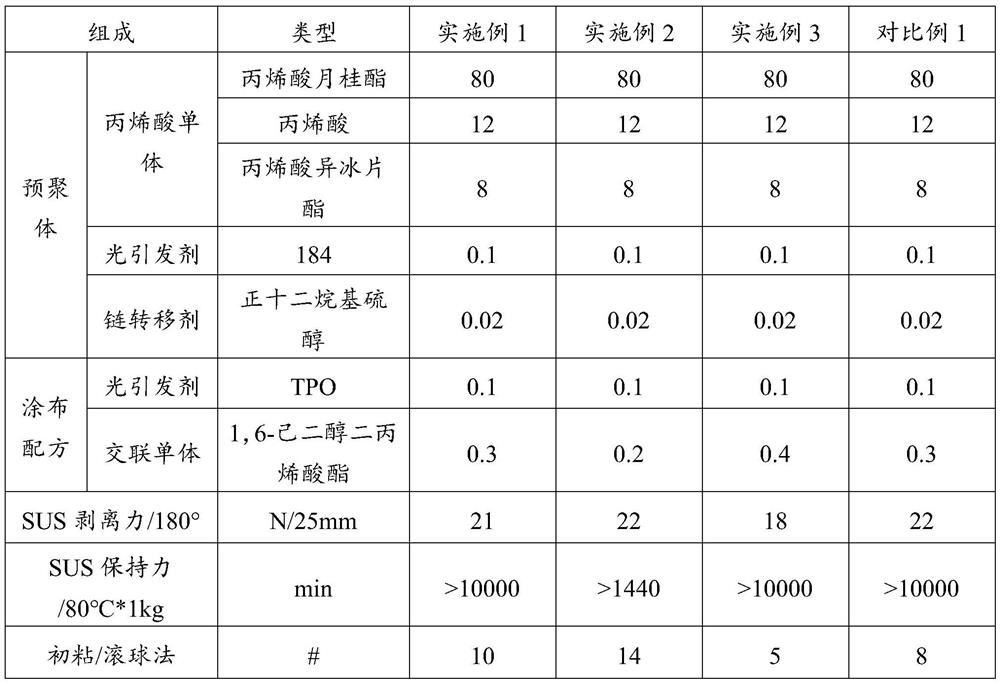

[0023] (1) Synthesis of prepolymer: Take 80 parts of lauryl acrylate, 12 parts of acrylic acid, 8 parts of isobornyl acrylate, 0.1 part of 184, and 0.02 parts of n-dodecyl mercaptan into a three-necked flask, and pass nitrogen gas to remove oxygen , after stirring evenly, turn on the ultraviolet lamp to irradiate, wait for the reaction viscosity to be 800-1500CPS, and the temperature change is 15°C, stop the light, and obtain the acrylic acid prepolymer;

[0024] (2) Coating formulation preparation: Take 100 g of the above-mentioned oligomer, 0.3 part of 1,6-hexanediol diacrylate, and 0.1 part of initiator TPO, and stir evenly to obtain a UV-curable propylene pressure-sensitive adhesive.

[0025] (3) Vacuum defoam the glue, coat it on the polyester release film with a coating thickness of 50 μm, and cure it with UVLED light. The wavelength of the curing lamp light source used is 365nm, and the curing energy is 1000-2000mJ / cm 2 ; Get a backing-free pressure-sensitive adhesive t...

Embodiment 2

[0027] (1) Coating formulation: Take 100 g of the oligomer synthesized in Example 1, 0.2 part of 1,6-hexanediol diacrylate, and 0.1 part of initiator TPO, and stir evenly to obtain a UV-curable propylene pressure-sensitive adhesive.

[0028] (2) Vacuum defoam the glue, coat it on the polyester release film with a coating thickness of 50 μm, and cure it with UVLED light. The wavelength of the curing lamp light source used is 365nm, and the curing energy is 1000-2000mJ / cm 2 , to obtain a substrate-free pressure-sensitive adhesive tape.

Embodiment 3

[0030] (1) Coating formulation: Take 100 g of the oligomer synthesized in Example 1, 0.4 part of 1,6-hexanediol diacrylate, and 0.1 part of initiator TPO, and stir evenly to obtain a UV-curable propylene pressure-sensitive adhesive.

[0031] (2) Vacuum defoam the glue, coat it on the polyester release film with a coating thickness of 50 μm, and cure it with UVLED light. The wavelength of the curing lamp light source used is 365nm, and the curing energy is 1000-2000mJ / cm 2 , to obtain a substrate-free pressure-sensitive adhesive tape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com