Electrochemical hardness removal device and method based on vibration enhanced inverted descaling

A kind of reverse pole descaling and electrochemical technology, applied in chemical instruments and methods, vibration cleaning, cleaning heat transfer devices, etc., can solve the problems of large equipment footprint, small effective cathode area, and difficult to clean the scale layer on the cathode surface. , to reduce the equipment footprint, reduce the cathode and anode spacing, and improve equipment integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the electrochemical descaling device and method based on vibration-enhanced descaling of inverted poles of the present invention will be further described below in conjunction with specific examples.

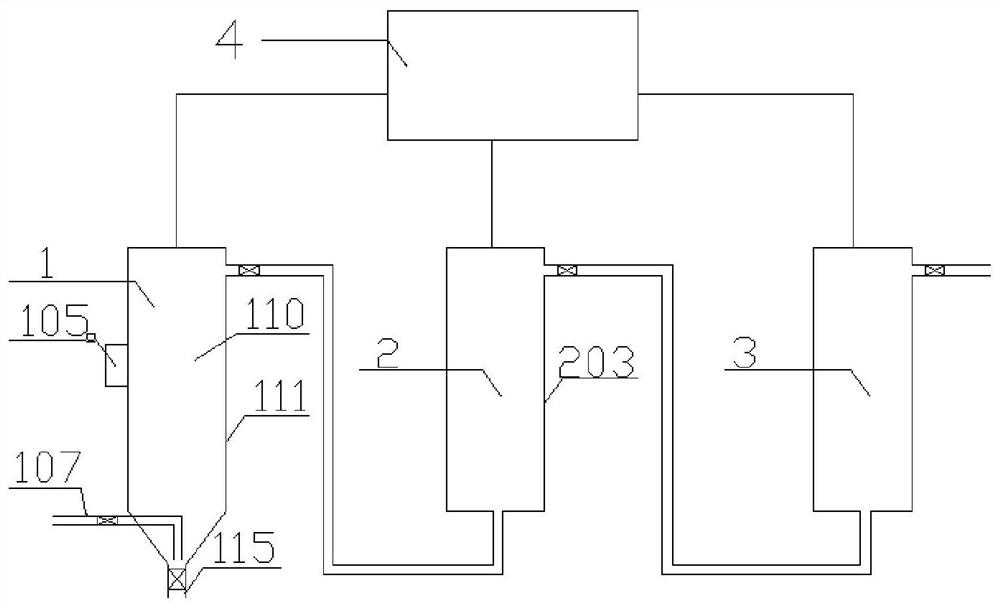

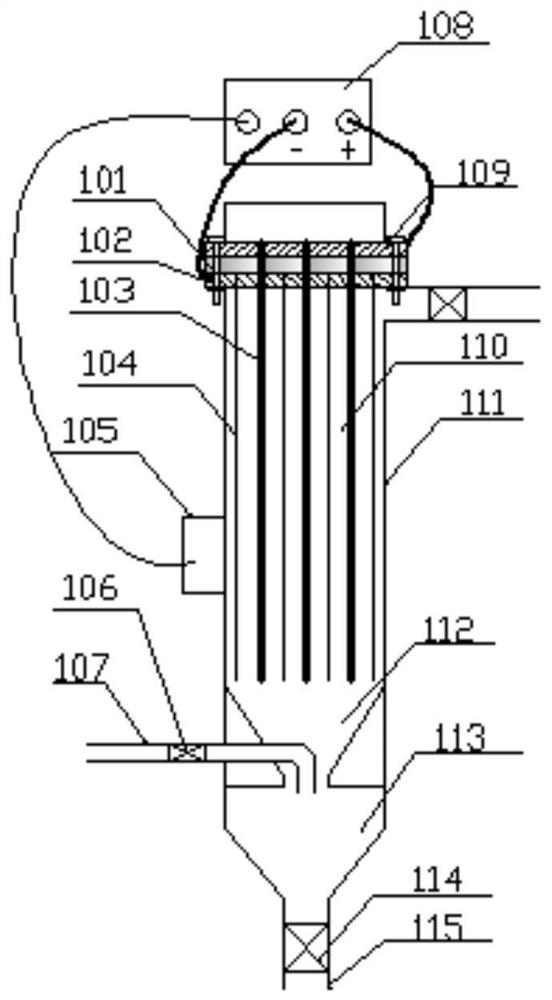

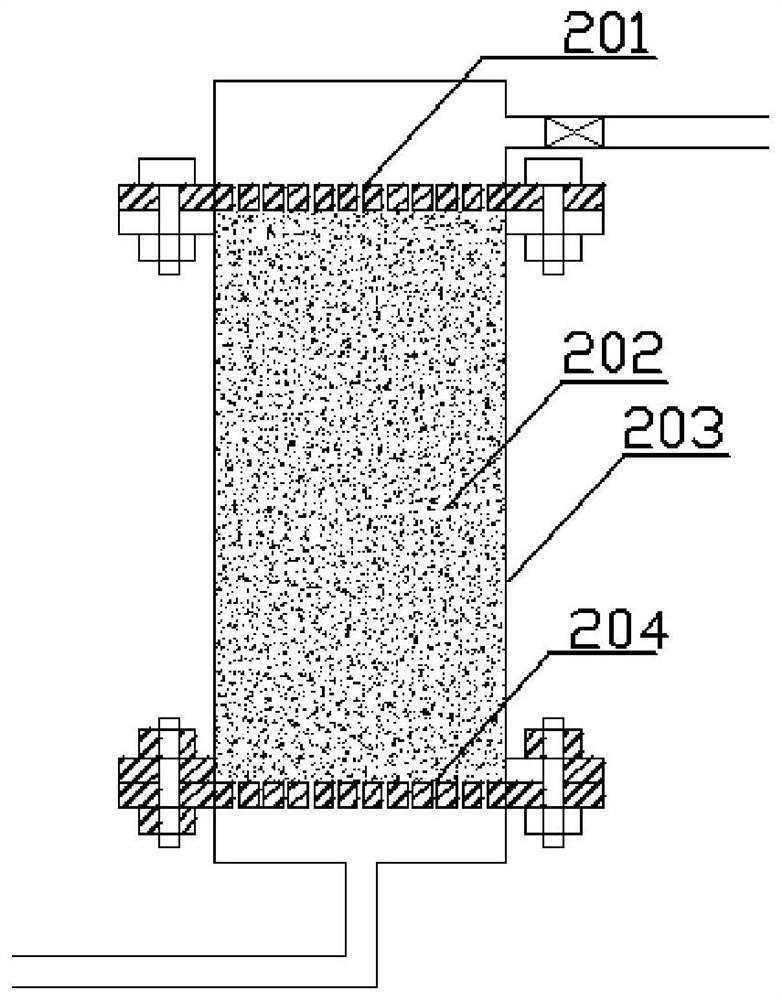

[0030] Such as figure 1 As shown, the present invention is based on the vibration-strengthened electrochemical descaling device for inverted pole descaling, which includes an electrolysis device 1, a filter tank 2 and a buffer tank 3 units connected in sequence, wherein the lower raw water inlet of the electrolysis device 1 and the raw water inlet pipe 107 connected, a vibration generator 105 ( figure 1 The vibration generator 105 used in the embodiment is introduced by taking a mechanical vibration generator as an example. A person skilled in the art can use an ultrasonic vibration generator according to the description in this specification, which will not be repeated here.) A slag discharge pipe 115 is arranged at the bottom. During operation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com