Stellite alloy welding and heat treatment process for modular production

A process method and modular technology, applied in welding equipment, welding accessories, metal processing equipment, etc., can solve the problem of unable to complete the welding of Stellite alloy blind plates, reduce the scope of welding heat affected zone, and avoid cracking. Defects, the effect of reducing welding stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be described in further detail below through specific examples.

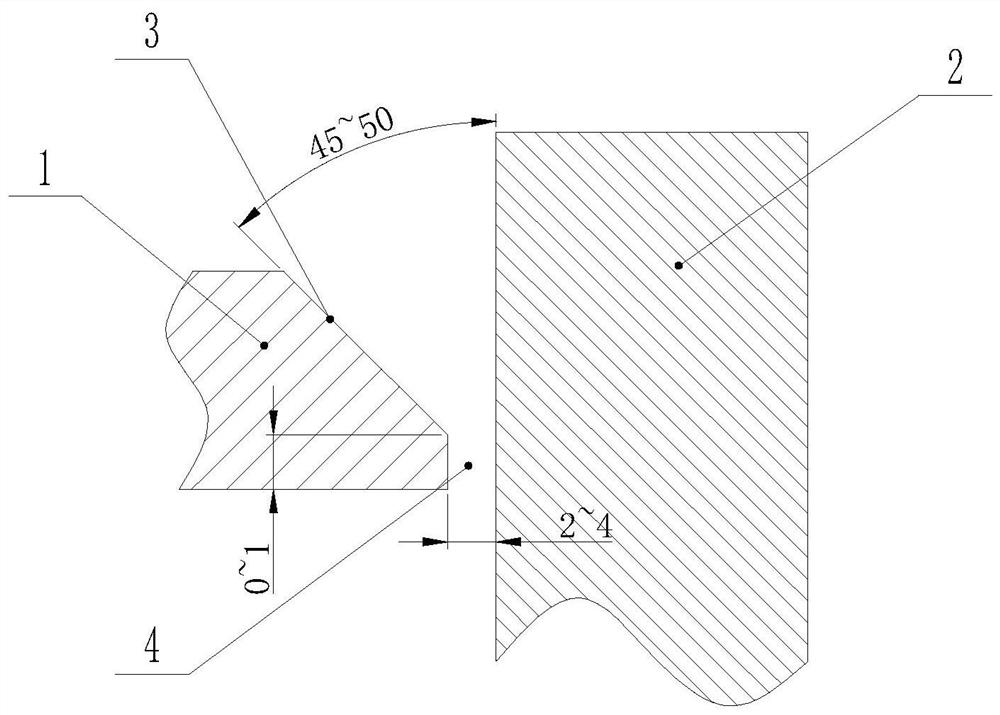

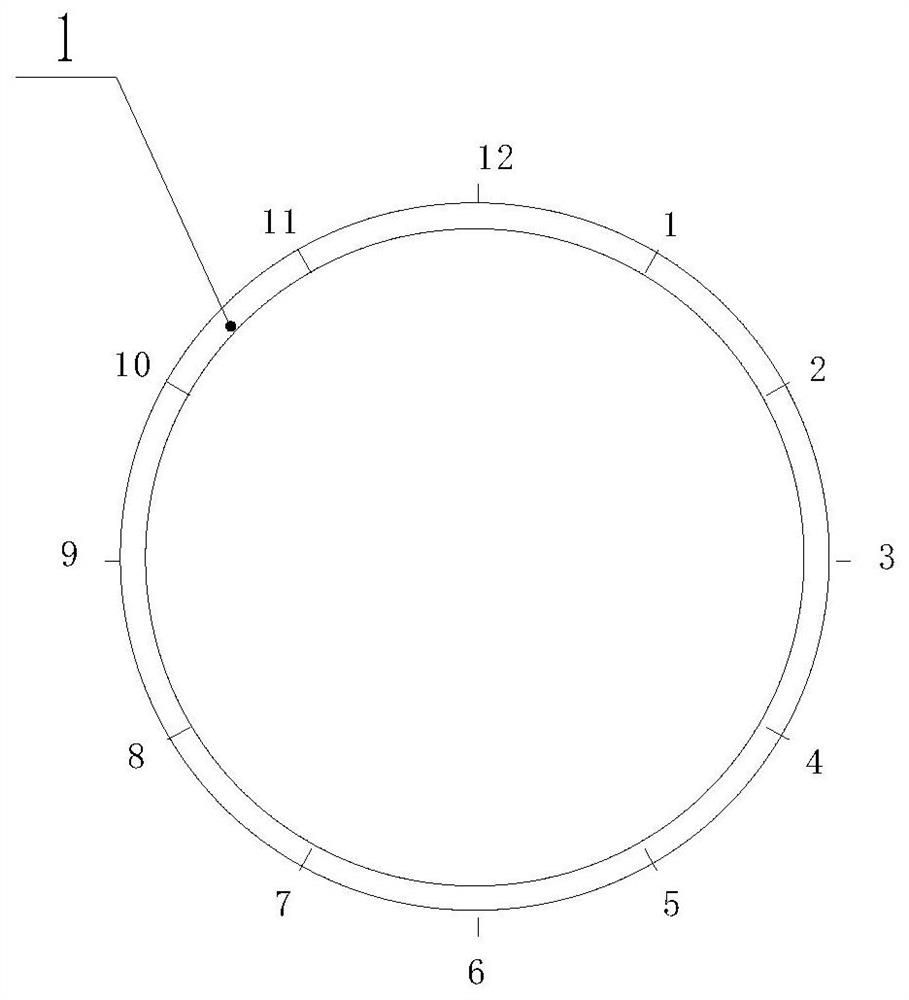

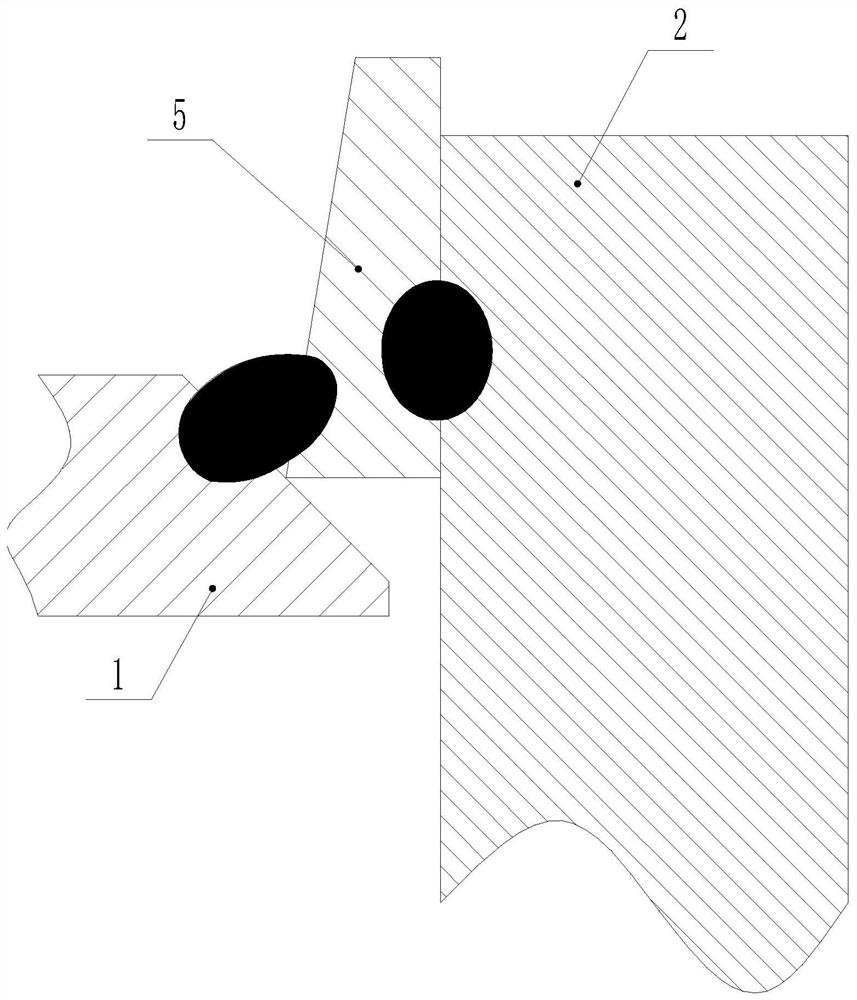

[0100] Such as Figure 1 to Figure 7 As shown, the Stellite alloy welding and heat treatment process method for modular production comprises the following steps:

[0101] A. Preparation before welding, including the following sub-steps:

[0102] a1) Determine the execution standards of welding and heat treatment;

[0103] a2) Check the specifications and grades of the base metal; whether the specifications, grades and gas of the welding consumables meet the standards;

[0104] The execution standard in this embodiment is:

[0105] ASME Ⅸ-2017 "Welding and Brazing Procedures, Welders, Brazers, Welding and Brazing Operators Qualification Standards";

[0106] ASME Ⅷ-1-2017 "Pressure Vessel Construction Rules"

[0107] a3) Select tool;

[0108] a4) acceptance inspection of tools;

[0109] The welding equipment needed include: inverter DC argon arc / manual tungsten argon arc we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com