Foam concrete vegetation matrix and preparation and use method thereof

A foamed concrete and matrix technology, which is applied in the field of building materials, can solve the problems of not involving foamed concrete materials and the like, and achieve the effects of good water storage, convenient production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

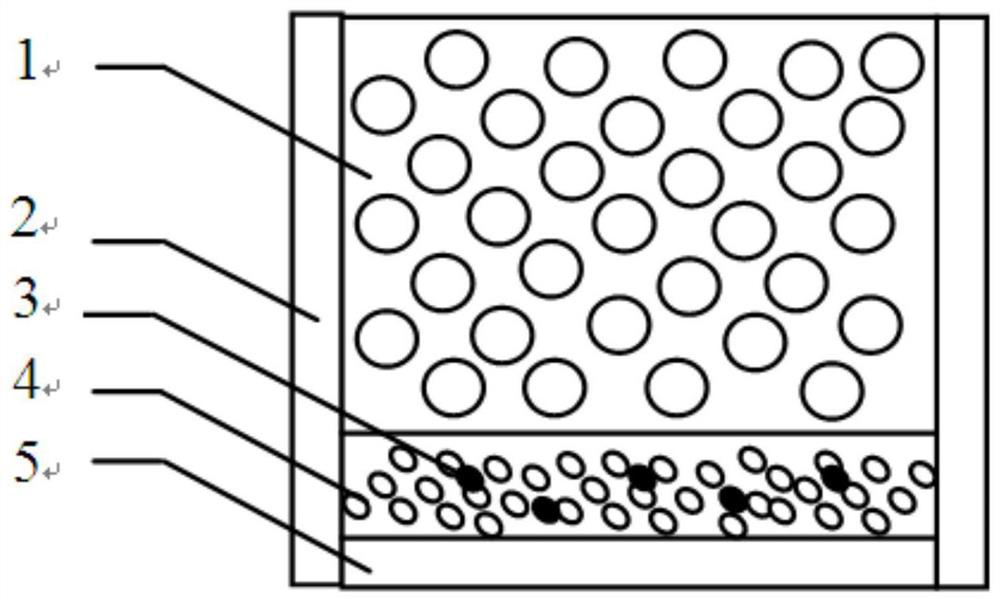

[0027] The preparation method of the foamed concrete planting substrate comprises the following steps:

[0028] (1) Prepare materials according to the proportion of foamed concrete planting substrate;

[0029] (2) Add plant seeds or seedlings to be planted into the SAP particles accounting for 0.2% to 0.5% of the mass of the foam concrete planting matrix, and pre-absorb 4% to 10% of the total water, and spread a thin layer evenly on the bottom of the mold , the thickness of the thin layer is 0.5cm~1cm;

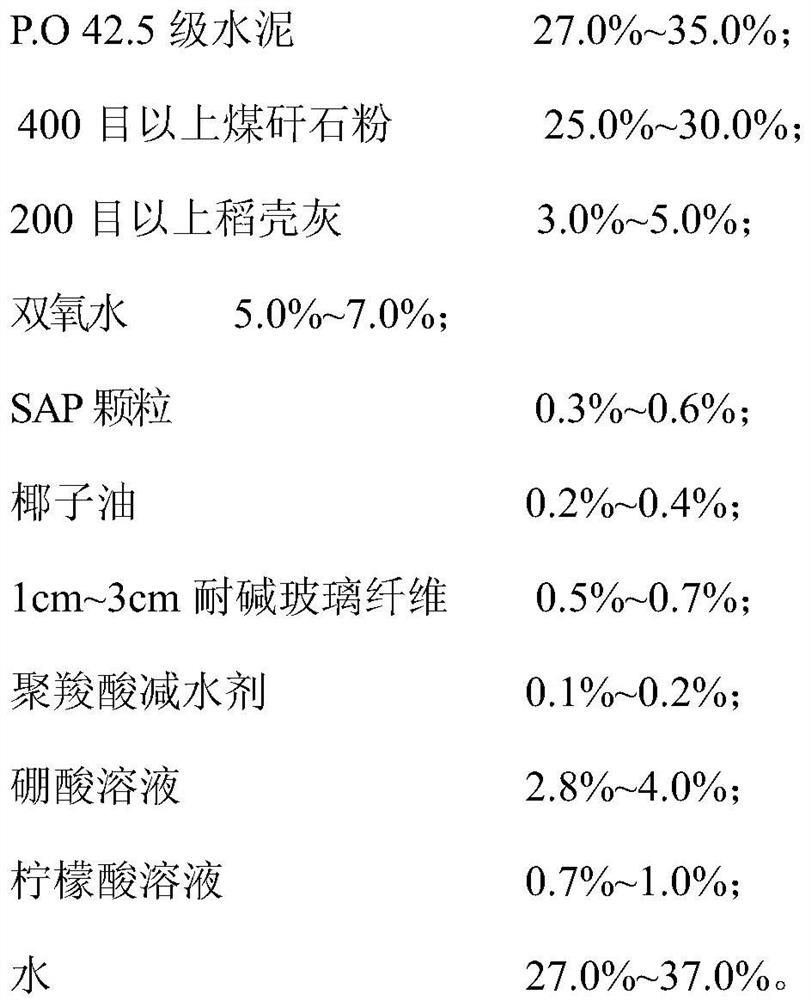

[0030] (3) After the remaining SAP particles are pre-absorbed with 2.8% to 4.0% boric acid solution and 0.7% to 1.0% citric acid solution, mix them with P.O 42.5 grade cement, coal gangue powder above 400 mesh, and rice husk above 200 mesh in proportion Mix ash, coconut oil, 1cm~3cm alkali-resistant glass fiber, polycarboxylate superplasticizer and remaining water evenly to obtain a slurry, then add hydrogen peroxide into the slurry in proportion, and continue stirring for 15...

Embodiment 1

[0037] A growth foam concrete matrix, consisting of the following components by weight percentage:

[0038]

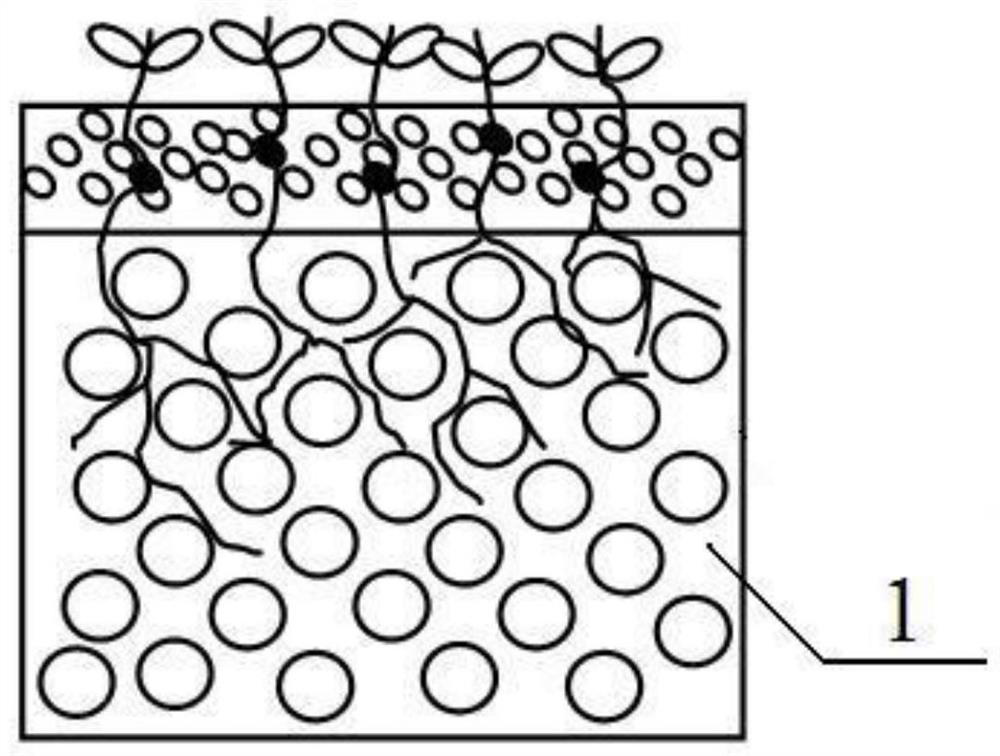

[0039] Proportionally, first mix the SAP particles accounting for 0.3% of the mass of the foam concrete planting substrate with the tall fescue seeds to be planted, and after pre-absorbing an appropriate amount of water, spread a thin layer of 0.5cm to 1cm thick on the bottom of the mold; After the remaining SAP particles are pre-absorbed with 3% boric acid solution by mass percentage and 1% citric acid solution by mass percentage, they are mixed with P.O 42.5 grade cement, coal gangue powder above 400 mesh, rice husk ash above 200 mesh, coconut oil, and 1cm~ Mix 3cm alkali-resistant glass fiber, polycarboxylate water reducer, and remaining water evenly, then add 30% hydrogen peroxide in proportion to the slurry and continue stirring for 15-25s to obtain a foamed slurry; mix the foamed slurry The body is poured into the mold, and the hardening strength is greater th...

Embodiment 2

[0042] A growth foam concrete matrix, consisting of the following components by weight percentage:

[0043]

[0044] Proportionally, the SAP particles accounting for 0.2% of the mass of the foamed concrete planting substrate are first mixed with the tall fescue seeds to be planted, and after pre-absorbing an appropriate amount of water, a thin layer of 0.5cm to 1cm thick is uniformly spread on the bottom of the mold; After the remaining SAP particles are pre-absorbed with 3% boric acid solution by mass percentage and 1% citric acid solution by mass percentage, they are mixed with P.O 42.5 grade cement, coal gangue powder above 400 mesh, rice husk ash above 200 mesh, coconut oil, and 1cm~ Mix 3cm alkali-resistant glass fiber, polycarboxylate water reducer, and remaining water evenly, then add 30% hydrogen peroxide in proportion to the slurry and continue stirring for 15-25s to obtain a foamed slurry; mix the foamed slurry The body is poured into the mold, and the hardening s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com