Composite material, preparation method thereof and quantum dot light-emitting diode

A composite material and initiator technology, applied in the direction of organic semiconductor device materials, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of reducing the performance and stability of QLED devices, and achieve improved stability, improved performance indicators, The effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

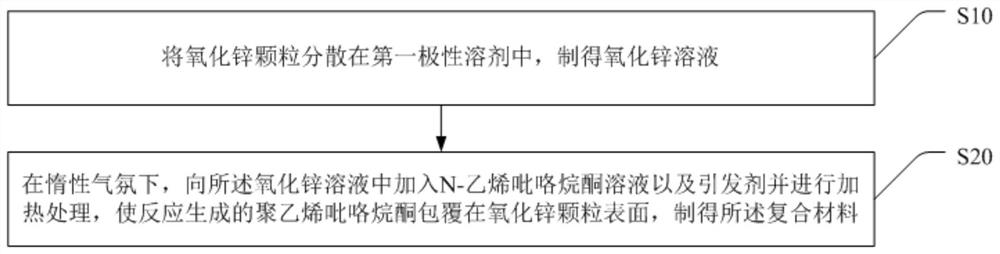

[0062] 1. The preparation steps of composite materials are as follows:

[0063]To a volume of 20ml, a concentration of 30mg / ml of the ZnO ethanol solution, respectively add 20ml of N-vinylpyrrolidone o-dichlorobenzene solution (volume ratio of 1:4) and 2.5mg of AIBN, then at 80 ° C, under an inert gas atmosphere Reaction 36h, obtain product;

[0064] After the reaction was completed, it was naturally cooled to room temperature, and the product was repeatedly dissolved and precipitated by ethanol and ether, and finally vacuum-dried to obtain a composite material.

[0065] 2. The steps for preparing QLED devices are as follows:

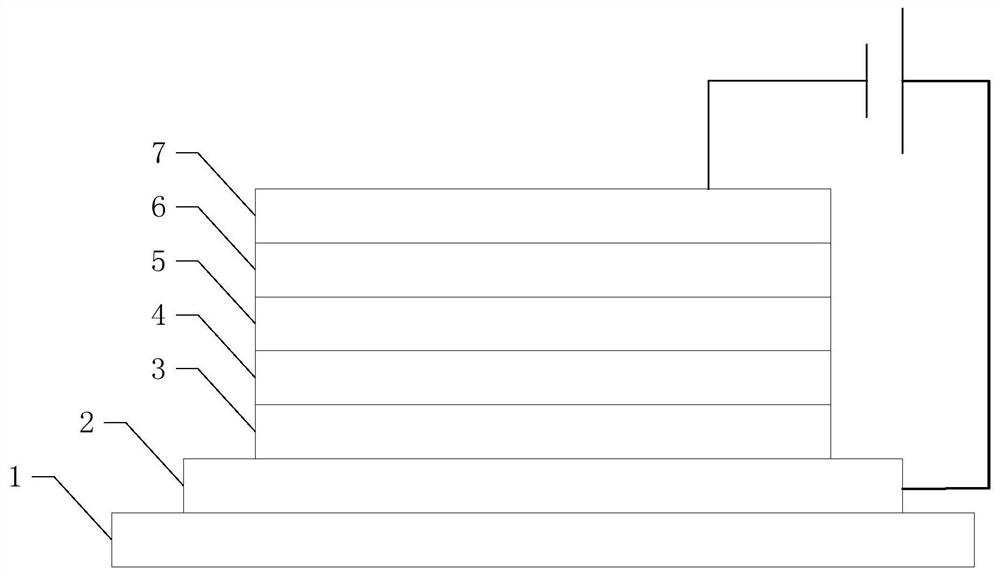

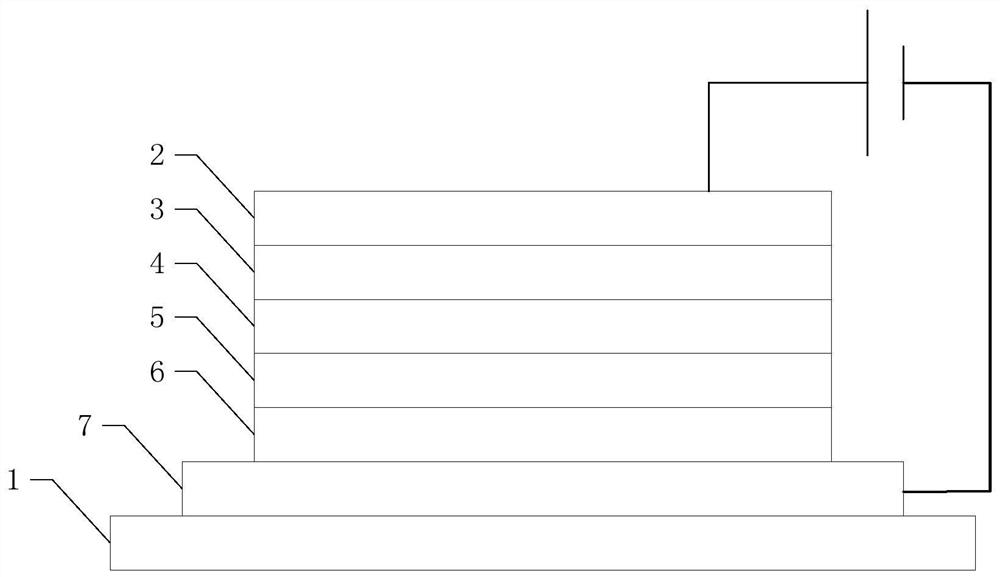

[0066] A bottom electrode, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, and a top electrode are sequentially prepared on the substrate. Wherein, the substrate is a glass substrate; the bottom electrode is ITO with a thickness of 120nm; the hole injection layer is PEDOT:PSS with a thic...

Embodiment 2

[0068] 1. The steps of composite materials are as follows:

[0069] Add 20ml of N-vinylpyrrolidone in o-dichlorobenzene solution (1:10 by volume) and 2.5mg of mercaptobenzothiazole to the ethanol solution of ZnO with a concentration of 30mg / ml in a volume of 20ml, and then at 100°C, inert Under the gas atmosphere, react for 24h to obtain the product;

[0070] After the reaction was completed, it was naturally cooled to room temperature, and the product was repeatedly dissolved and precipitated by ethanol and ether, and finally vacuum-dried to obtain a composite material.

[0071] 2. The steps for preparing QLED devices are as follows:

[0072] A bottom electrode, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, and a top electrode are sequentially prepared on the substrate. Wherein, the substrate is a glass substrate; the bottom electrode is ITO with a thickness of 120nm; the hole injection layer is PEDOT:PSS wi...

Embodiment 3

[0074] 1. The preparation steps of composite materials are as follows:

[0075] Be 20ml to volume, concentration is the o-dichlorobenzene solution (volume ratio is 1:5) of 10mlN-vinylpyrrolidone and 2.5mg methyl ethyl ketone peroxide in the ethanolic solution of ZnO that concentration is 60mg / ml, then at 150 °C, reacted for 36h under an inert gas atmosphere to obtain the product;

[0076] (2) After the reaction is finished, it is naturally cooled to room temperature, and the product is repeatedly dissolved and precipitated by ethanol and ether, and finally vacuum-dried to obtain a composite material.

[0077] 2. The steps for preparing QLED devices are as follows:

[0078] A bottom electrode, a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, and a top electrode are sequentially prepared on the substrate. Wherein, the substrate is a glass substrate; the bottom electrode is ITO with a thickness of 120nm; the hole i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com