Wavelength-controllable cellulose iridescent film and preparation method thereof

A cellulose and iridescent film technology, which is applied in the field of preparation of functional film materials, can solve the problems of high cost, high energy consumption, and unsuitability for large-scale production of enterprises, and achieve the effects of low cost, convenient operation, and time-saving preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

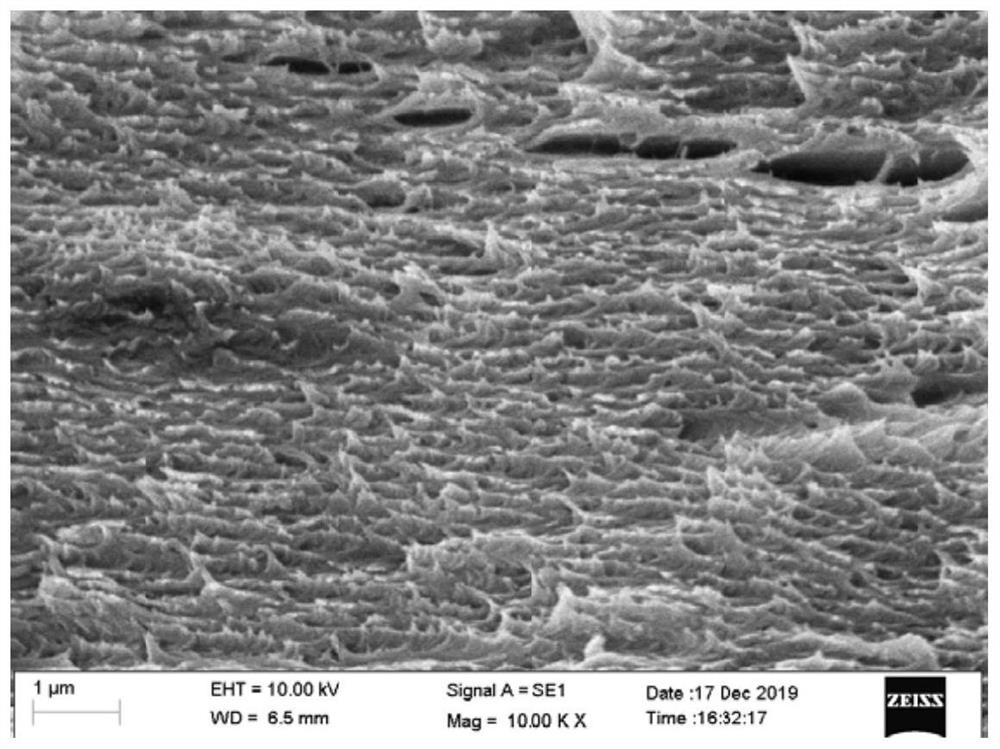

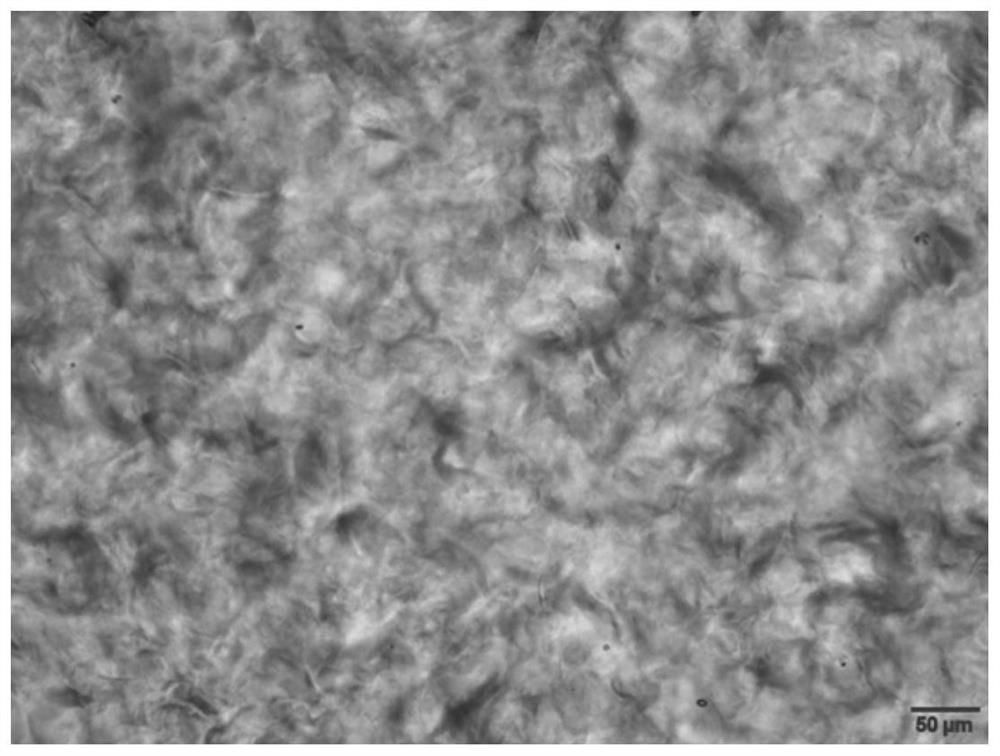

Image

Examples

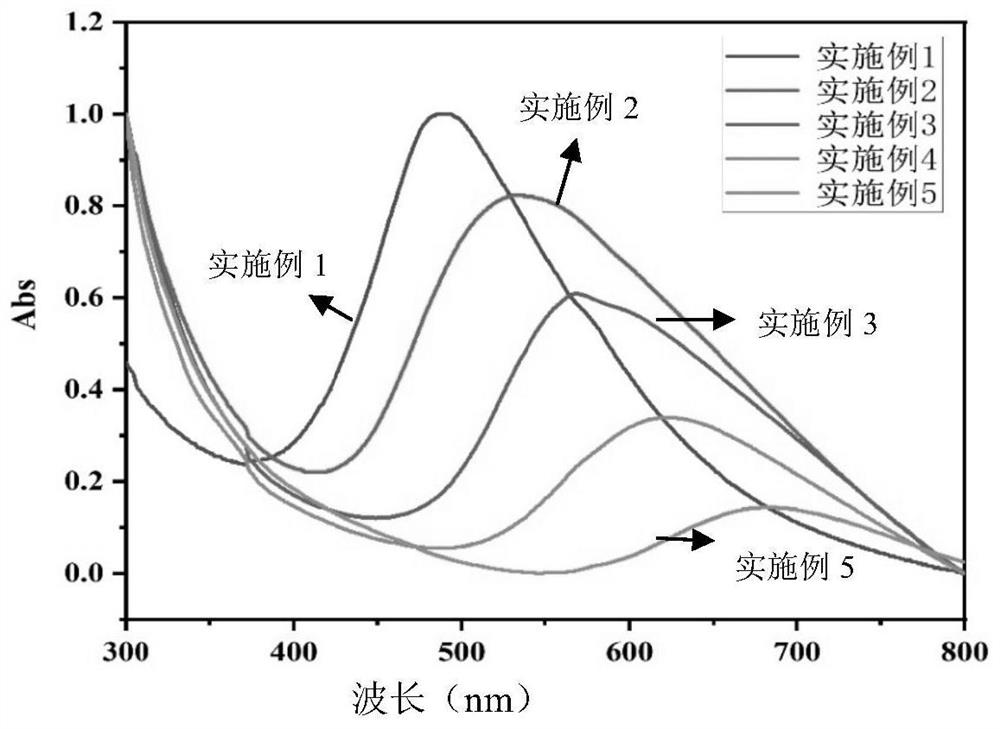

Embodiment 1

[0042] A preparation method of a wavelength controllable cellulose iridescent film containing lactic acid solution and glucose solution, comprising the steps of:

[0043] (1) 20 g of dry coniferous wood pulp is mixed with 200 ml of concentrated sulfuric acid solution with a concentration of 60 wt %, stirred at a speed of 400 r / min for 50 min at 50 ° C, and deionized water with 10 times the volume of concentrated sulfuric acid solution is added to terminate the reaction to obtain white milky solution;

[0044] (2) Centrifuge the white milky solution described in step (1) at a speed of 10,000 r / min for 10 min at 10° C., take the upper suspension, centrifuge 3 times, and combine the suspension;

[0045] (3) Pour the suspension described in step (2) into a dialysis bag with a molecular weight of 14000, and dialyze with deionized water until the suspension is neutral;

[0046] (4) The neutral suspension obtained in step (3) is concentrated by rotary steaming, the temperature of th...

Embodiment 2

[0050] A preparation method of a wavelength controllable cellulose iridescent film containing lactic acid solution and glucose solution, comprising the steps of:

[0051] (1) 20 g of dry coniferous wood pulp and 160 ml of concentrated sulfuric acid solution with a concentration of 70 wt % were stirred at 45 ° C for 55 minutes at a speed of 300 r / min, and deionized water with 10 times the volume of the concentrated sulfuric acid solution was added to terminate the reaction to obtain a white milky solution;

[0052](2) Centrifuge the white milky solution described in step (1) at a speed of 8000 r / min at 0°C for 12 minutes, take the upper layer suspension, repeat the centrifugation 4 times, and combine the suspension;

[0053] (3) Pour the suspension described in step (2) into a dialysis bag with a molecular weight of 14000, and dialyze with deionized water until the suspension is neutral;

[0054] (4) The neutral suspension obtained in step (3) is concentrated by rotary steamin...

Embodiment 3

[0058] A preparation method of a wavelength controllable cellulose iridescent film containing lactic acid solution and glucose solution, comprising the steps of:

[0059] (1) 20 g of dry coniferous wood pulp is mixed with 180 ml of concentrated sulfuric acid solution with a concentration of 64 wt %, stirred at 350 r / min for 45 min at 55 ° C, and deionized water with 10 times the volume of concentrated sulfuric acid solution is added to terminate the reaction to obtain white milky solution;

[0060] (2) Centrifuge the white milky solution described in step (1) at a speed of 10,000 r / min for 11 minutes at 5° C., take the upper layer suspension, repeat the centrifugation for 3 times, and combine the suspension;

[0061] (3) Pour the suspension described in step (2) into a dialysis bag with a molecular weight of 14000, and dialyze with deionized water until the suspension is neutral;

[0062] (4) Concentrate the neutral suspension obtained in step (3) by rotary steaming, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com