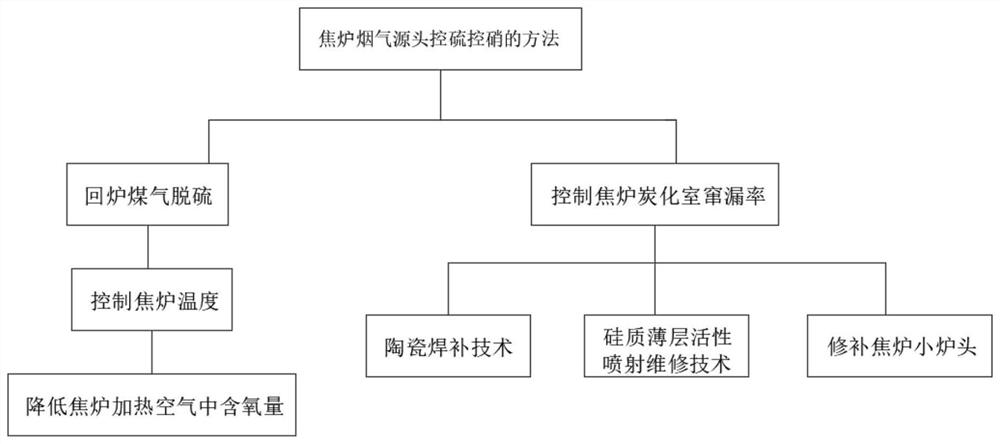

Method for controlling sulfur and nitrate from coke oven flue gas source

A coke oven and source technology, applied in the field of coking, can solve the problems of unsatisfactory control effect of sulfur content and nitrate content, pollution and other problems, and achieve the effect of direct control effect, obvious control effect and high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

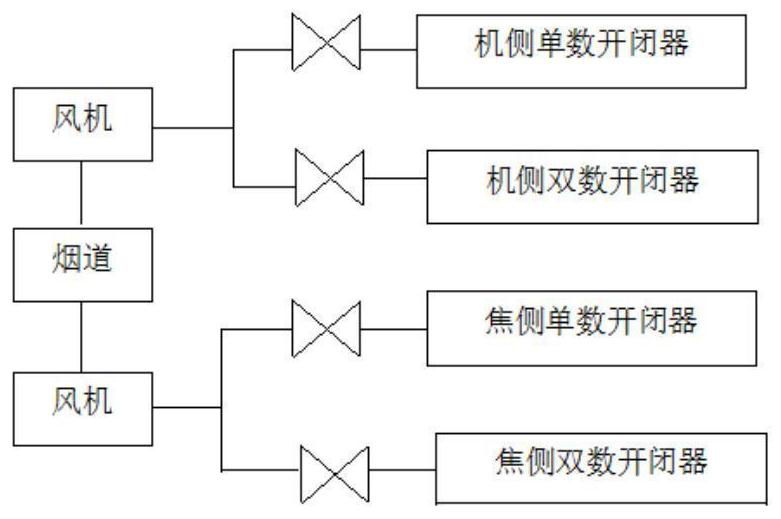

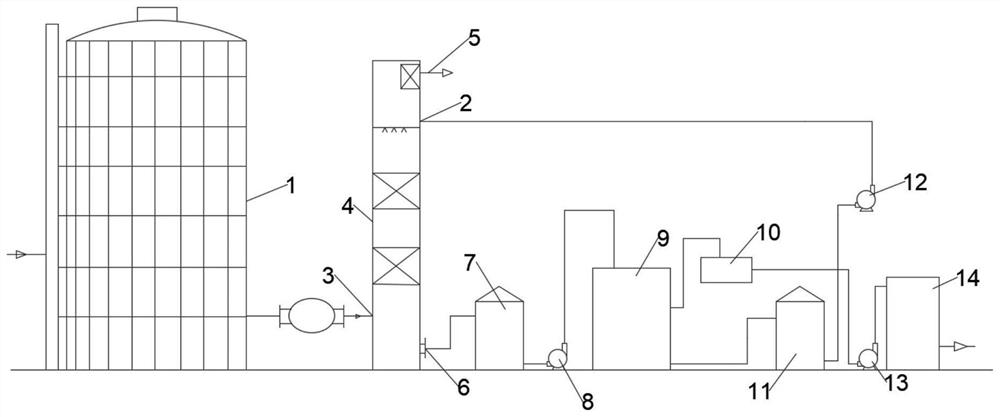

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for controlling sulfur and nitrification at the source of coke oven flue gas, including:

[0049] Step 1, desulfurization step:

[0050] The desulfurization step uses PDS wet desulfurization to desulfurize the returned furnace gas. After desulfurization, the hydrogen sulfide content in the returned furnace gas is 20mg / m 3 .

[0051] Return furnace gas refers to coke oven gas used for combustion in coke ovens, which is obtained from raw coal gas after gas purification, except for 90% H 2 In addition to S, also includes C 4 h 4 S, C 2 h 5 SH, CH 3 SH and CH 3 SCH 3 . Raw gas purification is to remove the H in the gas 2 S by 10g / m 3 Reduced to 300mg / m 3 , residual H in the gas after purification 2 S is the main source of sulfur dioxide in combustion flue gas, so to reduce the sulfur content from the source, it is necessary to deal with H 2 S.

[0052] The main principle of PDS wet desulfurization treatment of returned furnac...

Embodiment 2

[0059] This embodiment provides a method for controlling sulfur and nitrification at the source of coke oven flue gas, including:

[0060] Step 1, desulfurization step:

[0061] The desulfurization step uses PDS wet desulfurization to desulfurize the returned furnace gas. After desulfurization, the hydrogen sulfide content in the returned furnace gas is 20mg / m 3 .

[0062] Return furnace gas refers to coke oven gas used for combustion in coke ovens, which is obtained from raw coal gas after gas purification, except for 90% H 2 In addition to S, also includes C 4 h 4 S, C 2 h 5 SH, CH 3 SH and CH 3 SCH 3 . Raw gas purification is to remove the H in the gas 2 S by 10g / m 3 Reduced to 300mg / m 3 , residual H in the gas after purification 2 S is the main source of sulfur dioxide in combustion flue gas, so to reduce the sulfur content from the source, it is necessary to deal with H 2 S.

[0063] The main principle of PDS wet desulfurization treatment of returned furnac...

Embodiment 3

[0098] This embodiment provides a method for controlling sulfur and nitrification at the source of coke oven flue gas, including: a desulfurization step and a denitrification step.

[0099] The desulfurization step uses PDS wet desulfurization to desulfurize the returned furnace gas. After desulfurization, the hydrogen sulfide content in the returned furnace gas is 20mg / m 3 .

[0100] Return furnace gas refers to coke oven gas used for combustion in coke ovens, which is obtained from raw coal gas after gas purification, except for 90% H 2 In addition to S, also includes C 4 h 4 S, C 2 h 5 SH, CH 3 SH and CH 3 SCH 3 . Raw gas purification is to remove the H in the gas 2 S by 10g / m 3 Reduced to 300mg / m 3 , residual H in the gas after purification 2 S is the main source of sulfur dioxide in combustion flue gas, so to reduce the sulfur content from the source, it is necessary to deal with H 2 S.

[0101] The main principle of PDS wet desulfurization treatment of retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com