Grid mesh of cold cathode of terahertz vacuum electronic device and preparation method thereof

A vacuum electronic device, terahertz technology, applied in cold cathode manufacturing, electrode system manufacturing, electrical components and other directions, can solve the problems of flatness deformation, difficult operation, poor metal sheet strength, etc., to achieve high flatness retention and high security. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

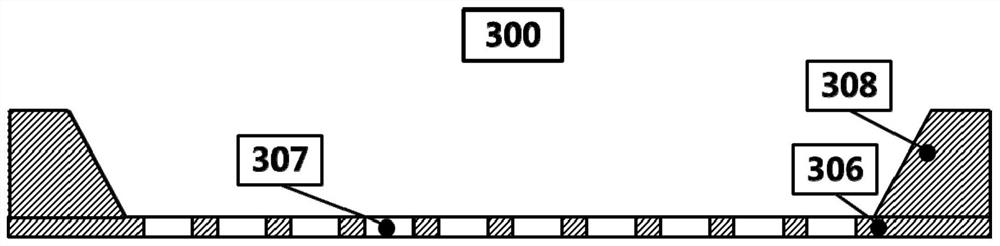

[0060] Such as image 3 As shown, the present embodiment provides a cold cathode grid 300 for a terahertz vacuum electronic device, which includes: a grid substrate 306, including a grid through-hole array 307 in the central area of the grid substrate 306; a grid support The ring 308 is located on the grid substrate 306, and the two are welded together; the material of the grid substrate 306 is selected from one of copper, nickel, chromium and gold.

[0061] The thickness of the grid substrate 306 ranges from 40 microns to 5 microns depending on the frequency band of the terahertz device. In this embodiment, the exemplary thicknesses are 30 microns to 5 microns, 30 microns to 15 microns, 30 microns to 20 micron, 20 micron to 5 micron, 18 micron to 5 micron, 15 micron to 5 micron, etc., preferably 20 micron. The material of the grid substrate 306 is selected from copper, nickel, chromium, gold, etc. suitable for electroplating. In this embodiment, copper is preferred.

[00...

Embodiment 2

[0089] Repeat Example 1, the difference is that in step 4), the pattern of the photoresist mold 304 formed by photolithography is a square column, the side length is 80 microns, and the distance between each column is 10 microns, and other conditions remain unchanged. In this implementation Example The result of the grid 300 obtained is similar to that of Example 1, except that the grid transparent array hole 307 is a square hole array, and the light transmittance is 80%.

Embodiment 3

[0091] Repeat Example 1, the difference is that in step 3), the coating thickness of photoresist 303 is changed to 12 microns; in step 5), the thickness of gate electroplating layer 305 is changed to 13 microns; Electroplated layer 305 / photoresist mold 304 mixed layer grinding thickness is changed to 11 microns, polishing thickness is changed to 10 microns, and other conditions are unchanged, the result of the grid 300 obtained in this embodiment is similar to that of Example 1, the difference is that the grid The thickness of the substrate 301 is 10 micrometers.

[0092] The method of the present invention breaks through the limitation that conventional laser processing or photolithography methods can only achieve a grid with a thickness exceeding 50 microns, and can realize an ultra-thin grid with any thickness (such as 5-20 microns) in the range of 5-50 microns, and The grid plane is not easily deformed, the surface finish is better than 100nm, and the edge of the through-h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com