Preparation method of polyamide-based water-based cross-linking dispersing agent and formaldehyde-free water-based polymer composite adhesive prepared from polyamide-based water-based cross-linking dispersing agent

A composite adhesive and water-based technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of difficulty in uniform spraying of particleboard, large amount of adhesive, and high cost, and achieve Good emulsification and dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

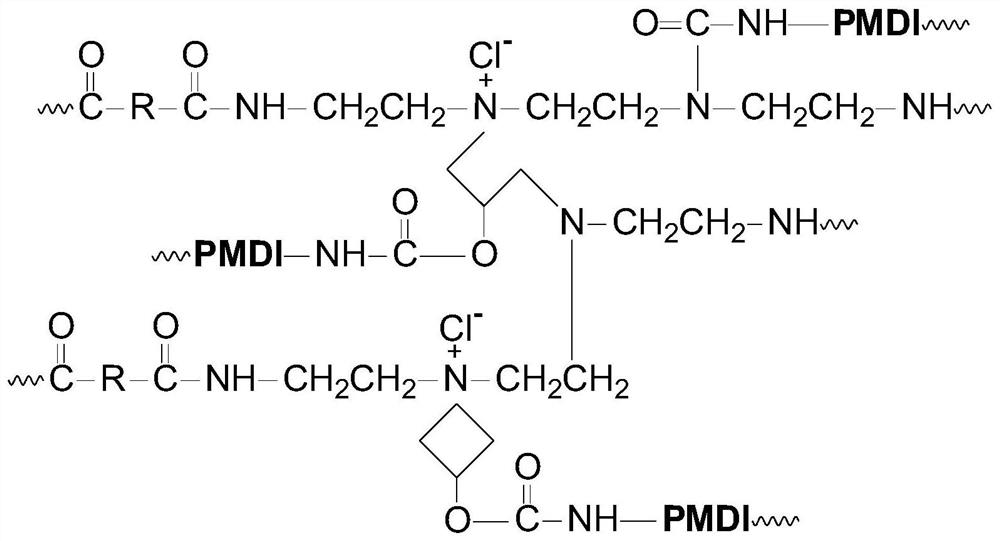

[0029] Specific embodiment one: the preparation method of polyamide-based water-based crosslinking dispersant in this embodiment is carried out according to the following steps:

[0030] 1. Stir and heat up to T 1 =45-130°C, keep for 30-45 minutes, then continue to heat up to distill water while the system is heating up, until the system does not distill any water or the system temperature reaches 195°C, then keep at 190°C-195°C for 2 hours;

[0031] 2. Stop heating, reduce the system temperature to 120°C, add 125 to 470 parts by weight of water until the temperature of the system drops below 30°C, and the mass concentration of the solids in the system is 30% to 50%;

[0032] 3. Take 100 parts by weight of the product obtained in step 2, add 130 to 250 parts by weight of water, stir evenly, add 5 to 35 parts of epichlorohydrin, and gradually heat up to T during stirring. 2 = 40-90°C, and keep the reaction at this temperature for about 4-8 hours, until the end point viscosity ...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the adipic acid / organic dibasic acid anhydride mixture in step 1 is a mixture of adipic acid and organic dibasic acid anhydride in any ratio. Others are the same as the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the organic dibasic anhydride in step 1 is one of maleic anhydride and phthalic anhydride or a mixture of the two in any ratio. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com