Bacillus amyloliquefaciens and application thereof to fermentation production of glutaminase

A technology for producing glutamine and glutaminase, applied in the directions of hydrolase, microorganism-based methods, enzymes, etc., can solve the problems of low yield, limited fermentation mode, low fermentation enzyme activity, etc., and achieves easy extraction and easy extraction. Product industrial production, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

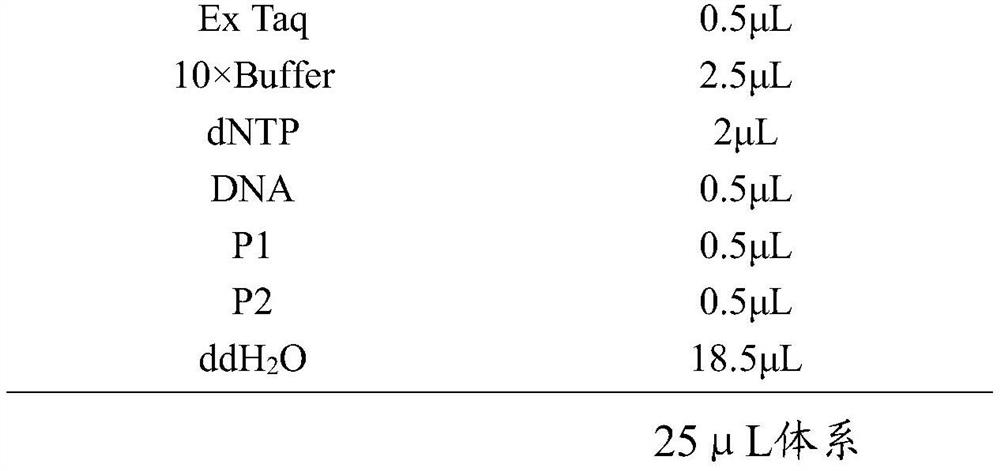

Image

Examples

Embodiment 1

[0055] The acquisition of embodiment 1 bacterial strain

[0056] (1) Isolation strain: the strain is isolated from the soil around the factory producing fermented bean curd or soy sauce. The specific operation steps are:

[0057] Sample collection: collect samples from the soil around the fermented bean curd or soy sauce factory or from the semi-finished fermented bean curd or fermented soy sauce;

[0058] Microbial enrichment: place the collected samples in a constant temperature environment at 37°C for more than 48 hours until dry; take an appropriate amount of dry samples and inoculate them into fresh medium for enrichment culture; the medium formula is glucose 1%, yeast powder 2 %, glutamine 0.06%, dipotassium hydrogen phosphate 0.05%, potassium dihydrogen phosphate 0.2% and magnesium chloride 0.1%, the balance is water

[0059] The enriched samples were plate cultured after serial dilution to obtain single colonies;

[0060] (2) Mutagen strains

[0061] Adopt ARTP muta...

Embodiment 2-1

[0078] Embodiment 2-1 fermentation produces glutaminase

[0079] (1) Strain activation: select glycerol tube strains and activate them in a fresh plate culture medium at 37°C for 18 hours to obtain a single colony. The components of the plate culture medium are: based on 100L of water, yeast powder 5g / L, peptone 10g / L, sodium chloride 10g / L;

[0080] (2) Seed preparation: select 1-2 single bacterium colonies after activation and transfer in the Erlenmeyer flask with fresh seed culture medium, (its composition and content are the same as the culture medium of step (1)) (500mL Fill 100mL feed solution in the Erlenmeyer flask), prepare seed solution, culture condition: 37 ℃, 200rpm culture 10h;

[0081] (3) Seed tank cultivation: the inoculum size is 0.3% by volume to inoculate the seed solution obtained in step (2) into 5L seed tanks containing the seed medium for cultivation, the cultivation temperature is 37°C, the rotating speed is 100rpm, and the ventilation ratio 1:0.8, ...

Embodiment 2-2

[0118] Embodiment 2-2 fermentation produces glutaminase

[0119] (1) Strain activation: select the glycerol tube strain and activate it in a fresh plate medium at 37°C for 18 hours to obtain a single colony. The components of the plate medium are the same as the components and contents of (1) in Example 2-1 same;

[0120] (2) Seed preparation: 1-2 single bacterium colonies activated in the selection step (1) are transferred to fresh seed medium (which has the same composition and content as the embodiment 2-1 step (2)) In the Erlenmeyer flask (250mL Erlenmeyer flask is equipped with 50mL feed liquid), prepare seed liquid, culture condition: 37 ℃, 200rpm culture 12h;

[0121] (3) Seed tank cultivation: the inoculum size is 0.2% by volume to inoculate the seed solution obtained in step (2) into a 5L seed tank containing the seed medium for cultivation, the cultivation temperature is 37°C, the rotating speed is 200rpm, the ventilation 1:1.1, cultured for 10 hours, wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com