Preparation method and application of an electrochromic glass device

An electrochromic glass and electrochromic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of complex preparation process of electrochromic glass, poor optical performance and long-term stability, high material cost, etc., to overcome high Barriers of cost and high price, improvement of color memory ability, effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

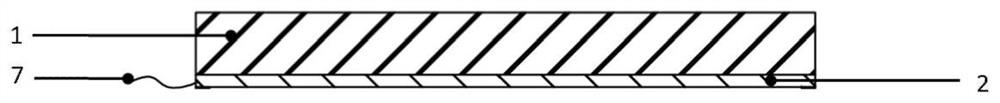

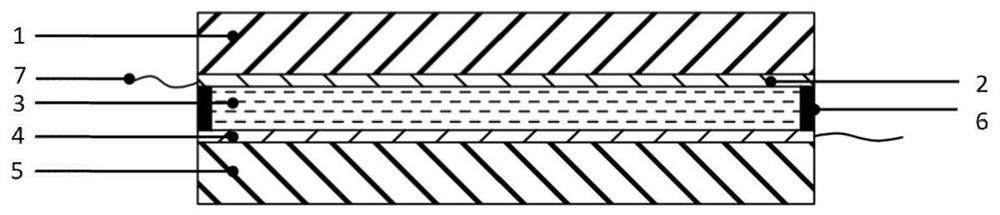

[0049] Preparation of electrochromic glass devices:

[0050] 1) Preparation of negative electrode:

[0051] First, a mesh metal negative electrode was prepared, and the electrodeposition method was used. The metal copper foil with a purity of 98% was used as the counter electrode, the 0.1mol / L copper sulfate aqueous solution was used as the electrolyte, and the stainless steel wire (Baoyungang stainless steel wire) with a diameter of less than 30 μm was used as the counter electrode. Working electrode, a voltage of -0.1V was applied to the working electrode of stainless steel wire for constant voltage deposition, and the deposition time was 300s, and a uniform metallic copper coating was obtained on the stainless steel wire.

[0052] The mesh metal negative electrode is attached to the negative electrode substrate, the negative electrode substrate is flat glass, and double-sided tape is pasted on the four sides of the flat glass, and then the obtained stainless steel wires coa...

Embodiment 2

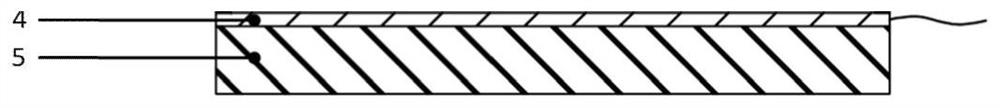

[0068] Preparation of electrochromic glass devices:

[0069] 1) Preparation of negative electrode:

[0070] First prepare a mesh metal negative electrode, mix metal tin and metal antimony (Sinopharm Reagent Co., Ltd.) with a purity of ≥99% in a weight ratio of 1:1, then heat to 500 ℃ to fully melt, and mix 100 mesh titanium mesh (Shengshida Metal Materials Co., Ltd.) ) immersed in the above-mentioned tin-antimony mixed melt and fully soaked, the titanium mesh was pulled out from the melt at a speed of 5 mm / min, and after cooling to room temperature, a uniform tin-antimony alloy coating was obtained on the titanium mesh.

[0071] The mesh metal negative electrode is attached to the negative electrode substrate, the negative electrode substrate is selected from PET film, and the obtained titanium mesh coated with the tin-antimony mixture coating is hot-pressed into the surface of the PET film using a heating plastic sealing machine, and cooled naturally to obtain Metal negative...

Embodiment 3

[0085] 1) Preparation of negative electrode:

[0086] First prepare a mesh metal negative electrode, immerse a 150 mesh nylon mesh (Jujian Technology) in a 1% graphene ethanol solution (Xianfeng Technology) by weight to fully infiltrate, and then remove the nylon mesh from graphene at a speed of 10 cm / min. The solution was pulled out and fully dried at 60°C to obtain a graphene-modified nylon mesh. Using the electrodeposition method, the graphene-modified nylon mesh was used as the working electrode, the nickel foam (Guangshengjia New Material) was used as the counter electrode, and 0.5mol / L nickel sulfate was used as the electrolyte. Constant voltage deposition was performed at a voltage of -0.15V, and the deposition time was 50s, and a uniform metallic nickel coating was obtained on the graphene-modified nylon mesh.

[0087] The mesh metal negative electrode is attached to the negative electrode substrate, and the negative electrode substrate is plexiglass, and the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com