Preparation method of high-stability inorganic hole transport film capable of being produced on large scale

A technology of hole transport and high stability, applied in the field of preparation of highly stable inorganic hole transport films, can solve the problems of high energy consumption and complicated steps, and achieve the effects of low energy consumption, low cost and blocking electron injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a highly stable inorganic hole transport thin film capable of large-scale production, comprising the following steps:

[0030] (1) Take 0.15mmol (0.0606g) ferric nitrate nonahydrate as iron source, 5mmol (1.2080g) copper nitrate trihydrate as copper source, 5mmol (2.0007g) chromium nitrate nonahydrate as chromium source, dissolve in 70ml to remove In deionized water, stir evenly, add 2.5g of sodium hydroxide, stir for 15 minutes, then transfer the mixed solution into a hydrothermal reaction kettle, and react at 230°C for 60h.

[0031] (2) Add dilute hydrochloric acid to the above product to adjust the pH of the solution to 7, then successively wash the product with deionized water and ethanol to remove impurities, and then disperse it in ethanol to obtain a concentration of 15 mg ml -1 Fe-CuCrO2 colloidal solution.

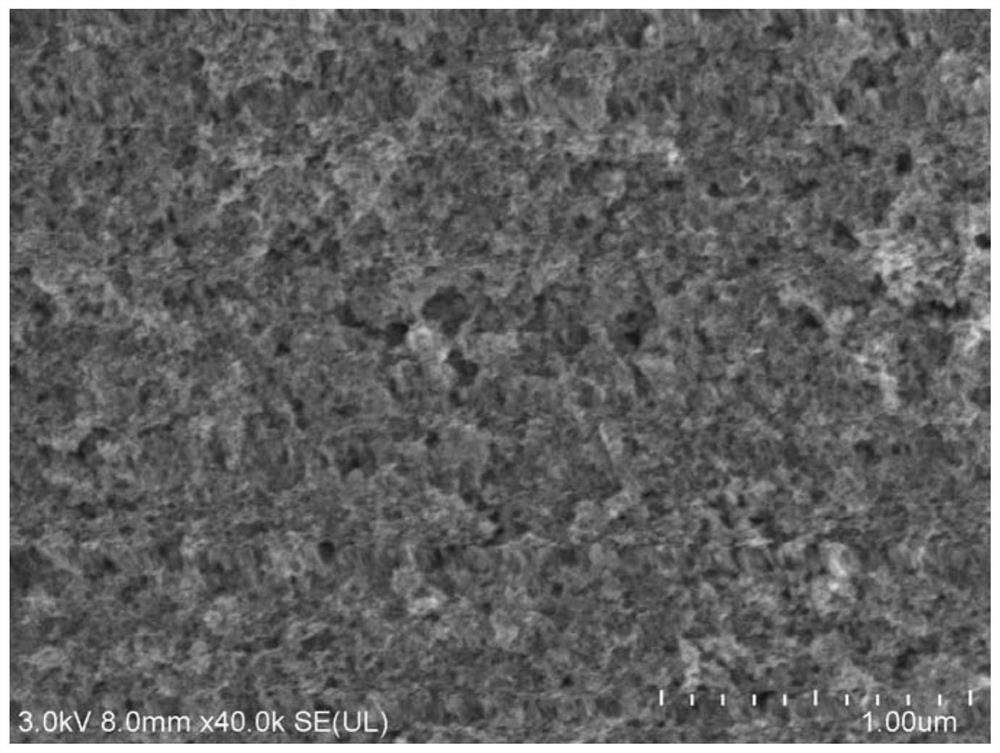

[0032] (3) Transfer the above colloidal solution to a spray gun, and spray it on the surface of the ITO conductive substrate prehea...

Embodiment 2

[0035] A method for preparing a highly stable inorganic hole transport thin film capable of large-scale production, comprising the following steps:

[0036] (1) Take 0.15mmol (0.0606g) ferric nitrate nonahydrate as iron source, 5mmol (1.2080g) copper nitrate trihydrate as copper source, 5mmol (2.0007g) chromium nitrate nonahydrate as chromium source, dissolve in 70ml to remove In deionized water, stir evenly, add 2.5g of sodium hydroxide, stir for 15 minutes, then transfer the mixed solution into a hydrothermal reaction kettle, and react at 230°C for 60h.

[0037] (2) Add dilute hydrochloric acid to the above product to adjust the pH of the solution to 7, then successively wash the product with deionized water and ethanol to remove impurities, and then disperse it in ethanol to obtain a concentration of 15 mg ml -1 Fe-CuCrO 2 colloidal solution.

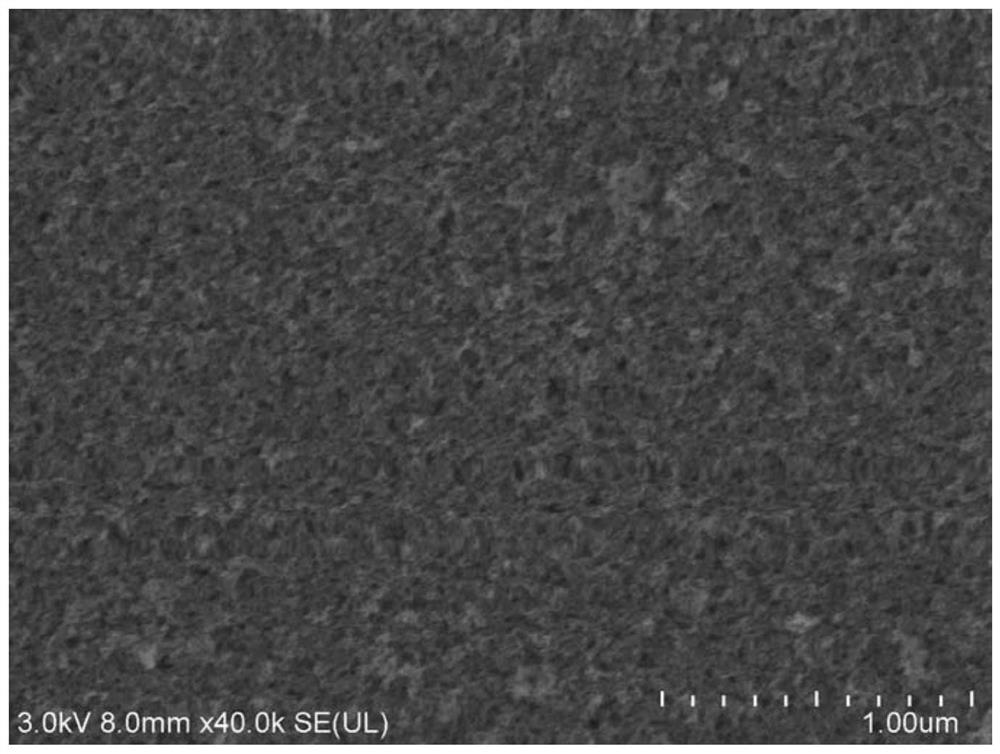

[0038] (3) Transfer the above colloidal solution to a spray gun, and spray it on the surface of an ITO conductive substrate prehe...

Embodiment 3

[0041] A method for preparing a highly stable inorganic hole transport thin film capable of large-scale production, comprising the following steps:

[0042] (1) Take 0.15mmol (0.0606g) ferric nitrate nonahydrate as iron source, 5mmol (1.2080g) copper nitrate trihydrate as copper source, 5mmol (2.0007g) chromium nitrate nonahydrate as chromium source, dissolve in 70ml to remove In deionized water, stir evenly, add 2.5g of sodium hydroxide, stir for 15 minutes, then transfer the mixed solution into a hydrothermal reaction kettle, and react at 230°C for 60h.

[0043] (2) Add dilute hydrochloric acid to the above product to adjust the pH of the solution to 7, then successively wash the product with deionized water and ethanol to remove impurities, and then disperse it in ethanol to obtain a concentration of 15 mg ml -1 Fe-CuCrO 2 colloidal solution.

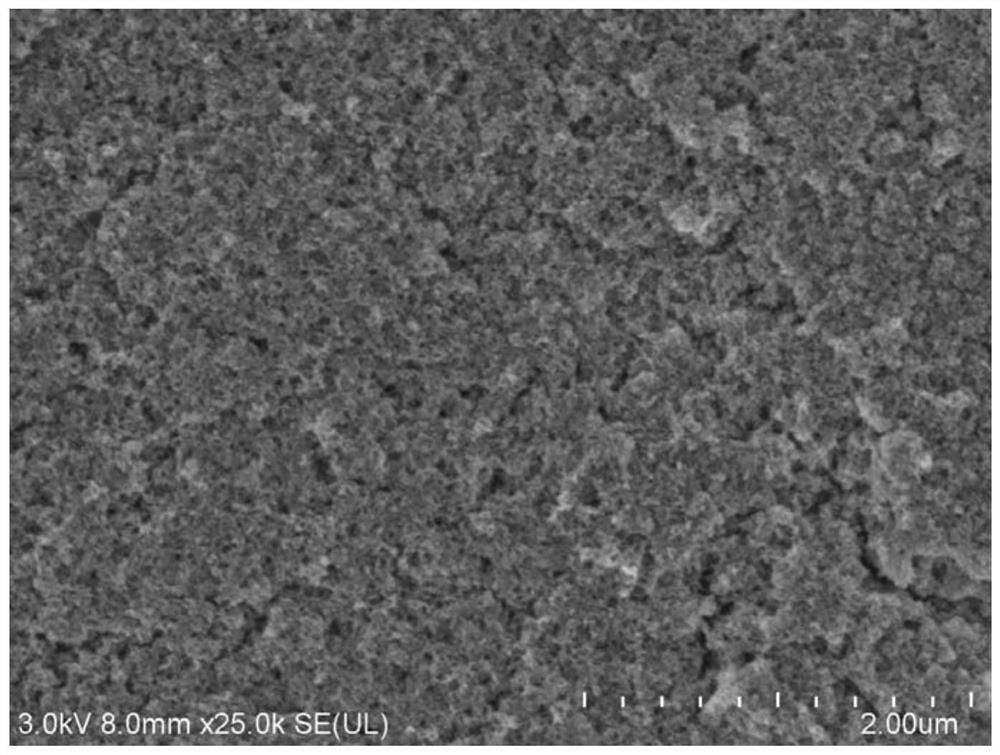

[0044] (3) Transfer the above colloidal solution to a spray gun, and spray it on the surface of the ITO conductive substrate preh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com