High-temperature-resistant anti-cracking concrete and preparation method thereof

A technology of concrete and high temperature resistance, which is applied in the field of concrete and can solve the problems of poor high temperature resistance and crack resistance of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

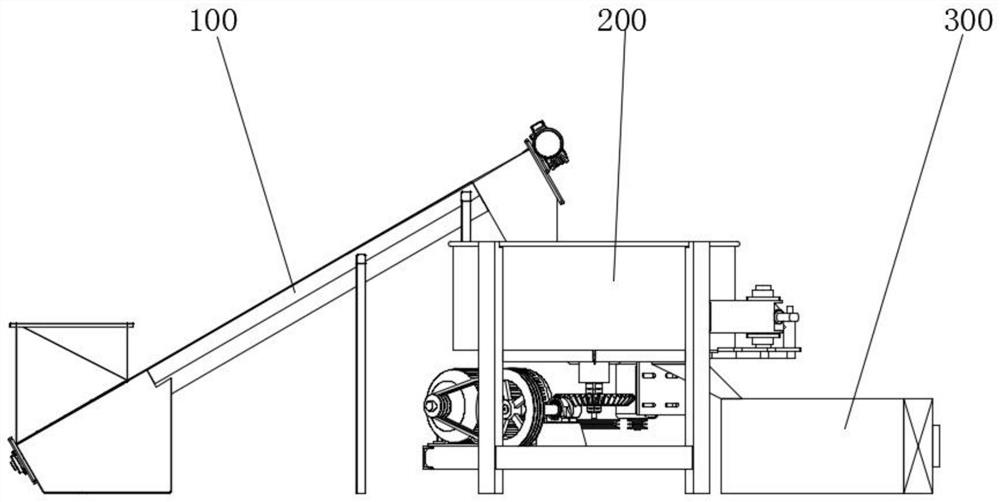

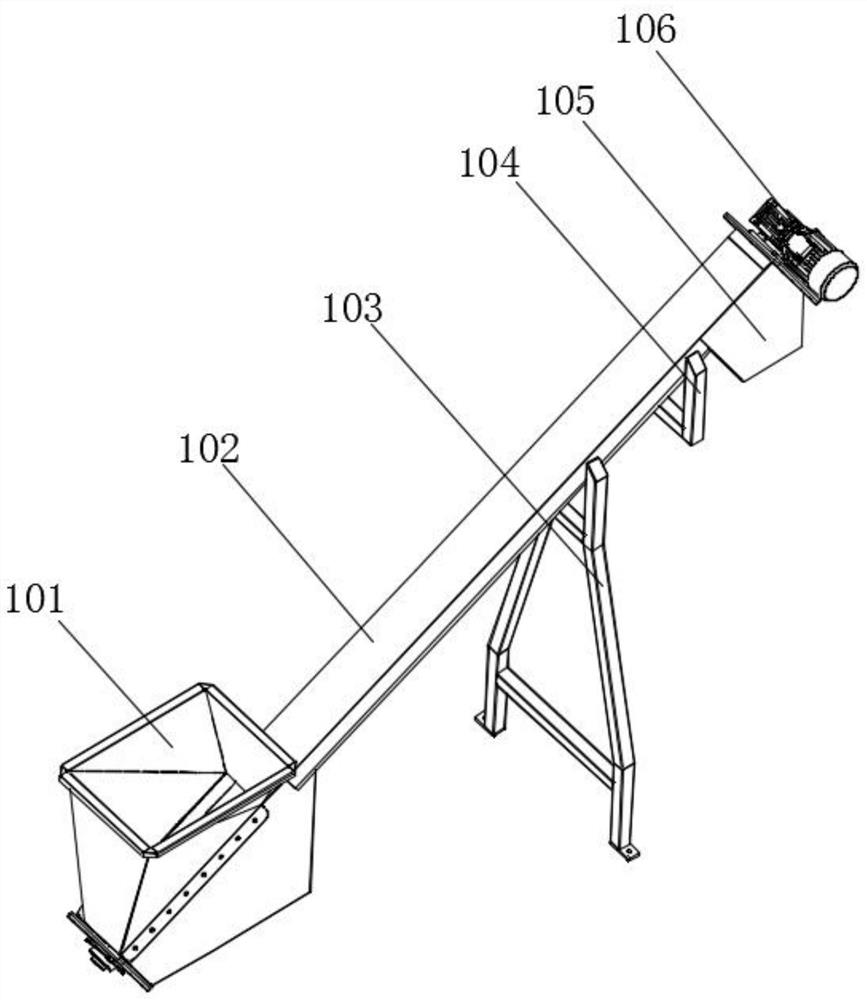

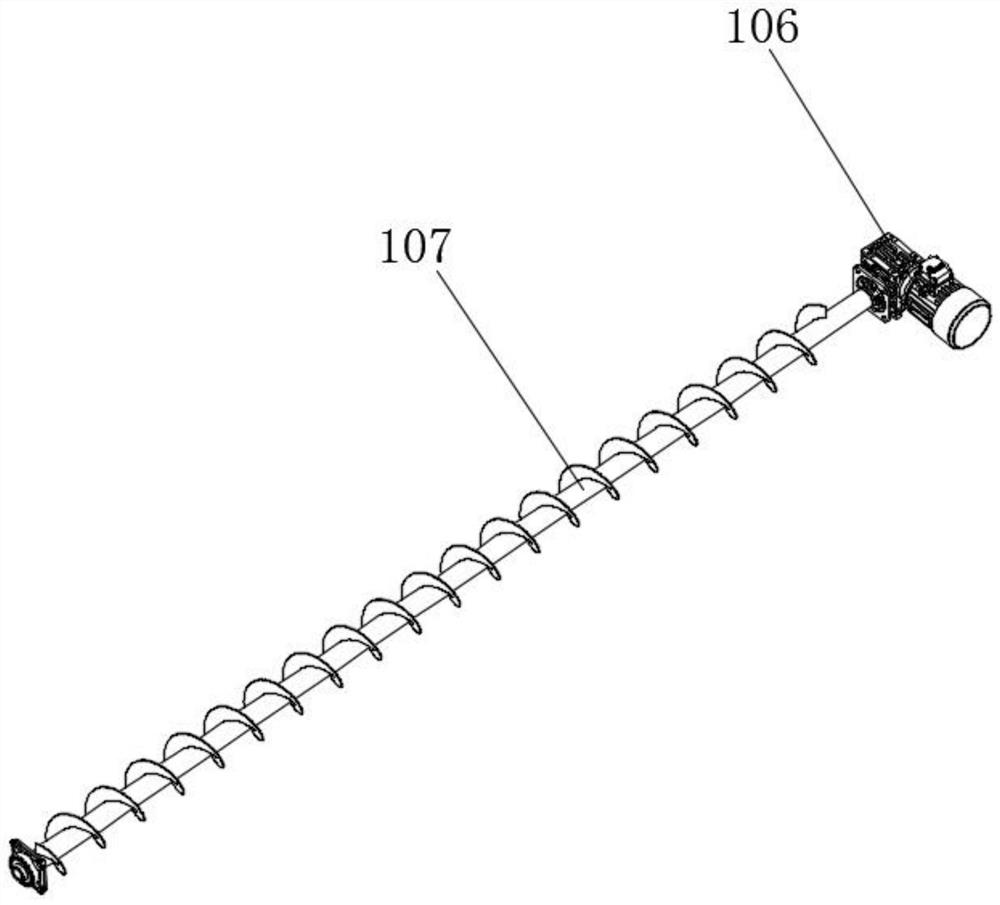

[0052] see Figure 1-9 As shown, the present embodiment is a kind of high-temperature-resistant and crack-resistant concrete, comprising the following components in parts by weight:

[0053] 60 parts of river sand, 100 parts of gravel, 50 parts of cement, 10 parts of water, 2 parts of nano-titanium dioxide, 10 parts of nano-silica, 16 parts of nano-carbon fiber, 3 parts of fly ash, 3 parts of EVA emulsion, 1 part of graphene , 2 parts of naphthalene-based water reducer.

[0054] A preparation method of high-temperature-resistant and crack-resistant concrete, comprising the following steps:

[0055] Step 1: Dissolving the naphthalene-based water reducer in water, then adding graphene, ultrasonically treating the graphene, dispersing the graphene until completely dissolved, and obtaining a graphene solution;

[0056] Step 2: adding EVA emulsion to the graphene solution, stirring evenly, and treating with ultrasonic waves to obtain a mixed solution;

[0057] Step 3: Add the mi...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that: a high-temperature-resistant and crack-resistant concrete includes the following components in parts by weight:

[0067] 70 parts of river sand, 110 parts of gravel, 60 parts of cement, 15 parts of water, 4 parts of nano-titanium dioxide, 13 parts of nano-silica, 18 parts of nano-carbon fiber, 4 parts of fly ash, 4 parts of EVA emulsion, 3 parts of graphene , 4 parts of naphthalene-based water reducer.

[0068] The performance of the high-temperature-resistant and crack-resistant concrete of Example 2 is detected, and the test results: the compressive strength at 25°C is 64.4Mpa, the compressive strength at 100°C is 60.1Mpa, the compressive strength at 200°C is 58.2Mpa, and the compressive strength at 500°C It is 46.3Mpa.

Embodiment 3

[0070] The difference between this embodiment and Embodiment 1 is that: a high-temperature-resistant and crack-resistant concrete includes the following components in parts by weight:

[0071] 80 parts of river sand, 120 parts of gravel, 70 parts of cement, 20 parts of water, 6 parts of nano-titanium dioxide, 16 parts of nano-silica, 20 parts of nano-carbon fiber, 5 parts of fly ash, 5 parts of EVA emulsion, 5 parts of graphene , 6 parts of naphthalene-based water reducer.

[0072]The performance of the high-temperature-resistant and crack-resistant concrete of Example 3 is detected, and the test results: the compressive strength at 25°C is 65.8Mpa, the compressive strength at 100°C is 62.3Mpa, the compressive strength at 200°C is 58.9Mpa, and the compressive strength at 500°C It is 47.5Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com