Epoxy resin for high-hardness and low-temperature curing type powder coating and preparation method

A technology of epoxy resin and powder coatings, which is applied in powder coatings, epoxy resin coatings, fireproof coatings, etc., and can solve the problem of unsatisfactory hardness, halogen-free flame retardant, salt spray resistance, flame retardancy and neutral salt spray resistance Slightly inferior, low crosslinking density of the coating film, etc., to achieve the effects of excellent flame retardancy and neutral salt spray resistance, improved water resistance and salt spray resistance, and high curing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of epoxy resin comprises the following steps:

[0038] A. Add the formula amount of melamine and formaldehyde into the reaction kettle, stir, raise the temperature to 55-60°C, and add a pH regulator to adjust the pH value to 8-9, and keep it warm for 3-5h;

[0039] B, when a large amount of hexahydroxymelamine solids are separated out, and when the free melamine is lower than 2%, stop the reaction, cool to 5-10°C, carry out decompression suction filtration, and obtain hexahydroxymelamine wet material;

[0040] C. Add the hexahydroxymelamine wet material obtained in step B and the hexafluorobutanol and cyclohexane of the formula amount into the reaction kettle, stir, add a pH regulator to adjust the pH value to 3-3.5, and then heat up to 85- At 90°C, carry out the butyl etherification reaction for 2-4 hours;

[0041] D. When the mass conversion rate of hexafluorobutanol reaches more than 90%, heat up to 100-120°C to remove solvent, water and unrea...

Embodiment 1

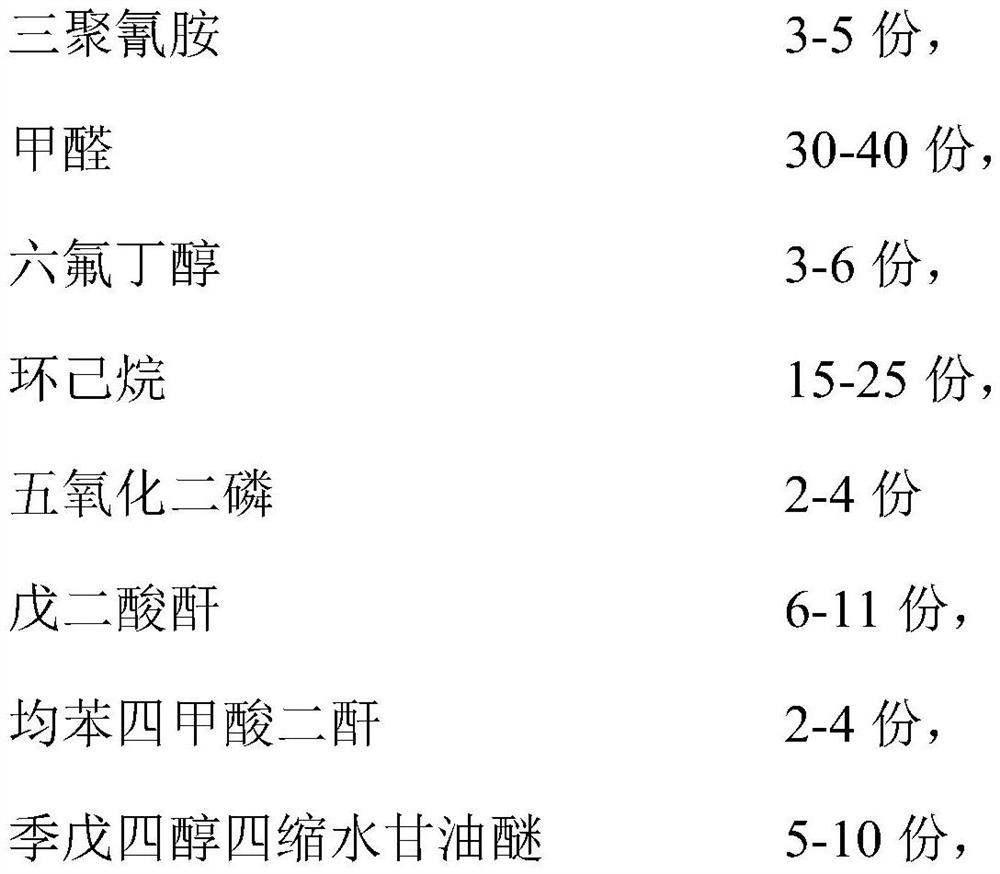

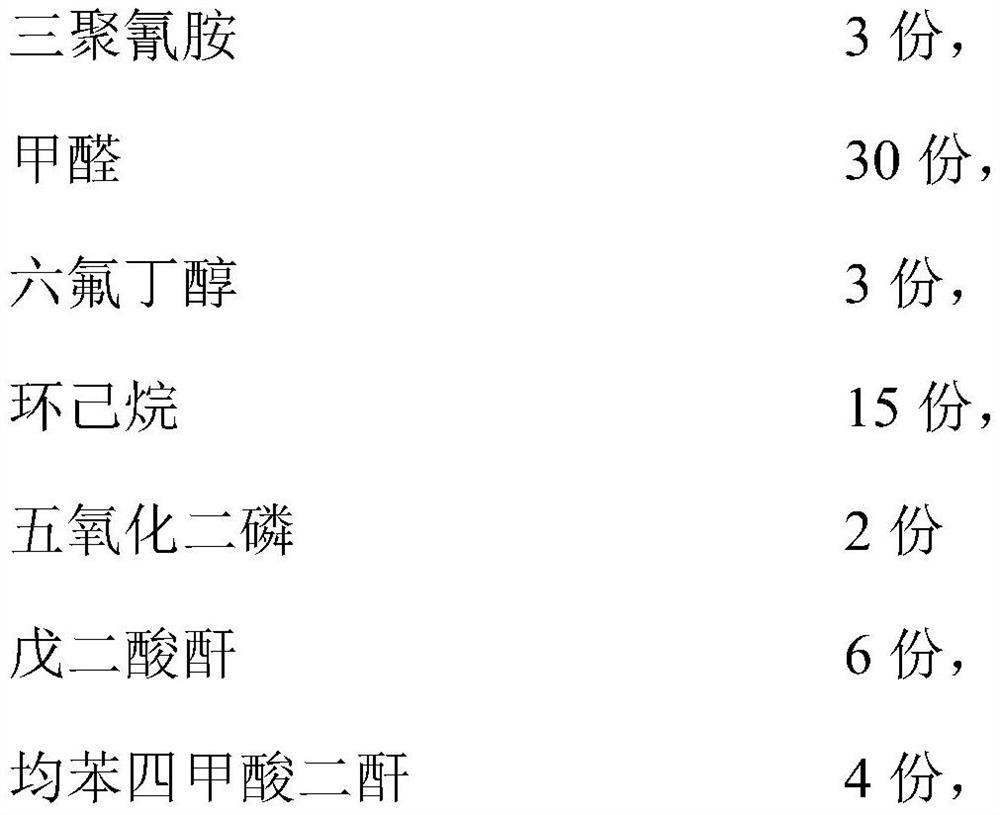

[0046] A kind of preparation method of epoxy resin for low-temperature curing powder coating, its raw material composition comprises in mole fraction:

[0047]

[0048]

[0049] The molar dosage of the catalyst is 0.15% of the molar dosage of pentaerythritol tetraglycidyl ether.

[0050] The epoxy equivalent of the prepared epoxy resin was 492g / mol, and the softening point was 86°C.

Embodiment 2

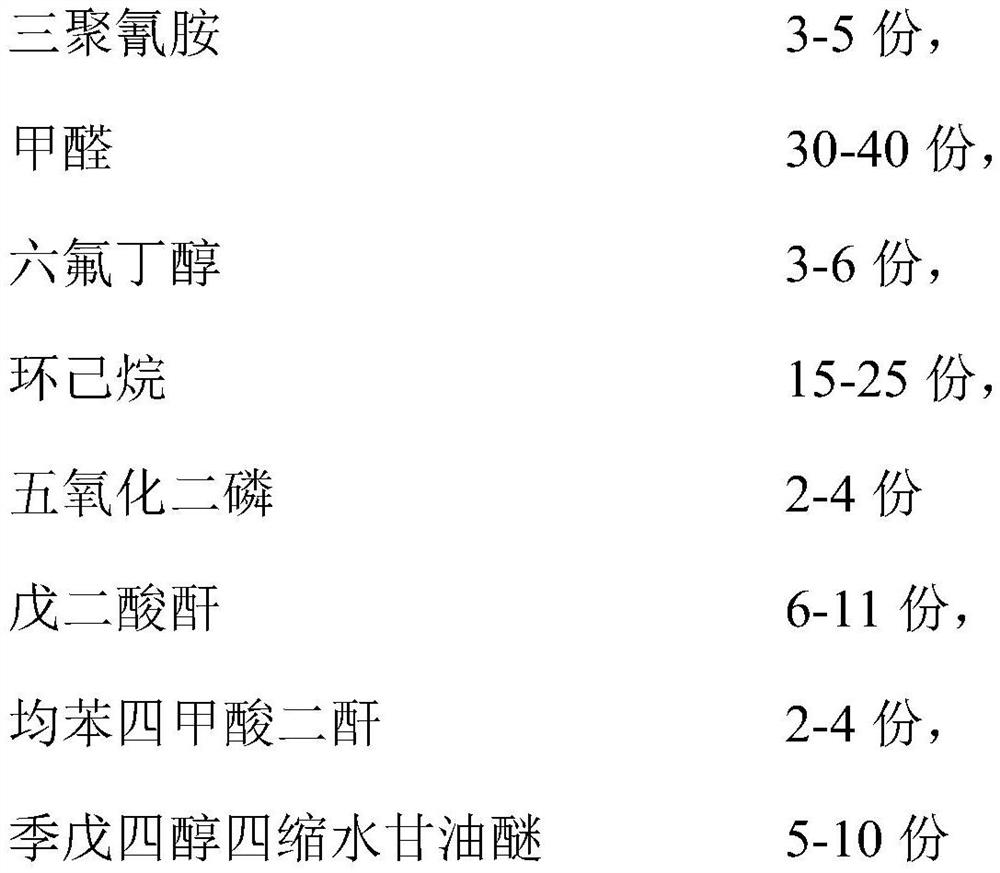

[0052] A kind of preparation method of epoxy resin for low-temperature curing powder coating, its raw material composition comprises in mole fraction:

[0053]

[0054] The molar dosage of the catalyst is 0.08% of the molar dosage of pentaerythritol tetraglycidyl ether.

[0055] The epoxy equivalent of the prepared epoxy resin was 409g / mol, and the softening point was 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com