Preparation method of novel organic-inorganic composite anion proton exchange membrane

A proton exchange membrane and inorganic composite technology, applied in the field of organic-inorganic composite anion proton exchange membrane and its preparation, to achieve high commercial application value, improve service life, and high proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

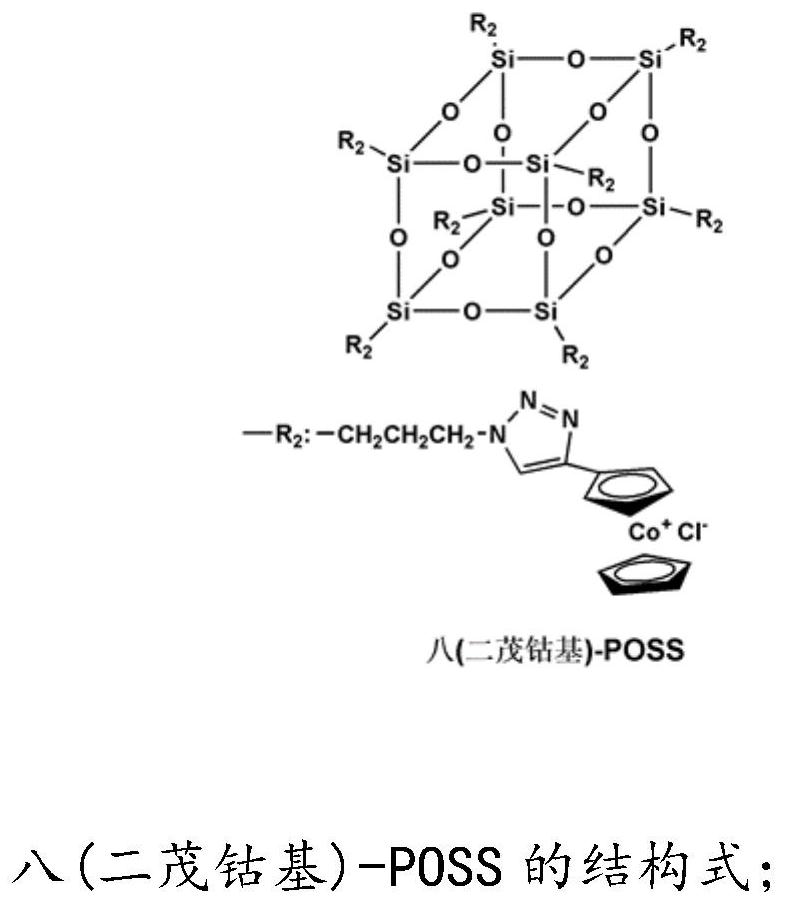

Method used

Image

Examples

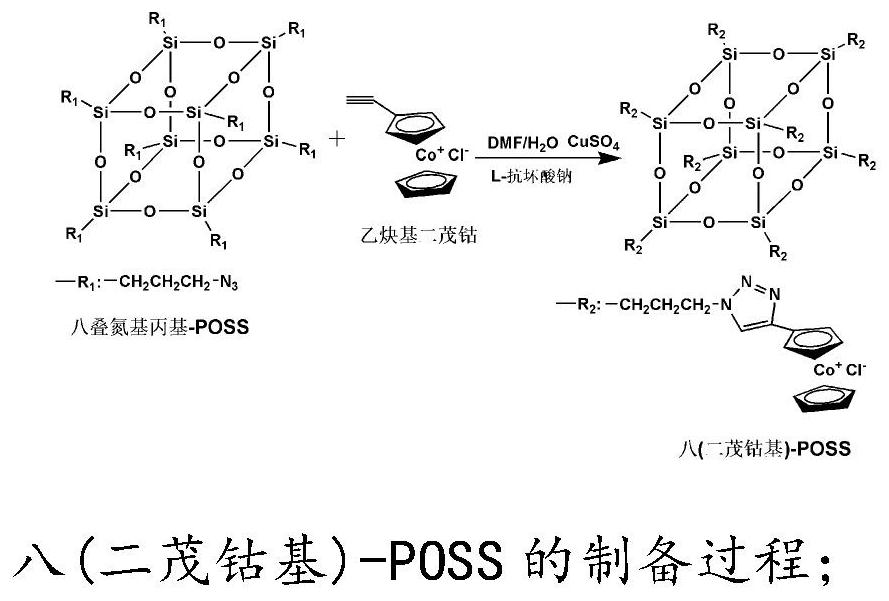

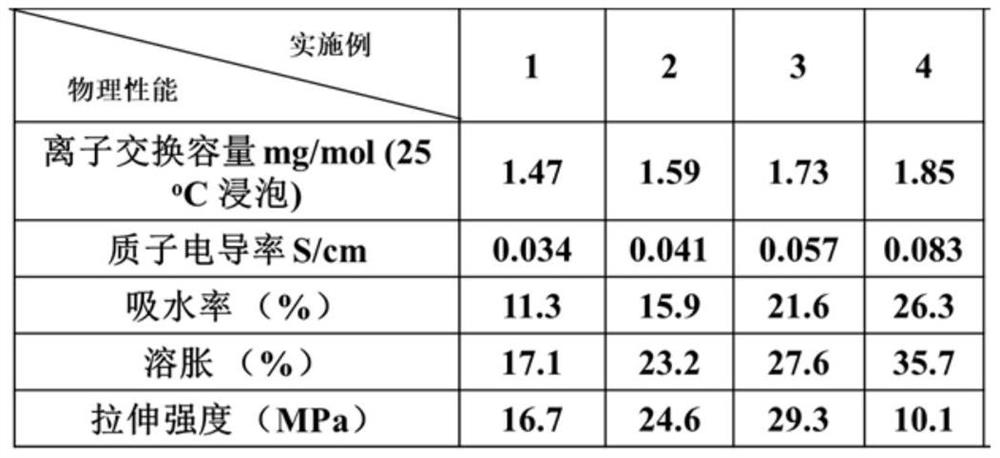

Embodiment 1

[0026] To prepare a new type of organic-inorganic composite anion proton exchange membrane, the specific steps are as follows: first weigh 0.300g octaazidopropyl-POSS and 1.190g ethynyl cobaltocene, and add it to 60mL THF and 20mL H 2 Then add 0.528g of copper sulfate and 1.901g of L-sodium ascorbate to a three-necked flask of O at 0°C, react at room temperature for 24h, and evaporate the solvent to obtain octa(cobaltocene-based)-POSS, which is put into an oven for use. Then weigh 1g of polyether ether ketone and put it into a three-necked flask containing 15mL dimethyl sulfoxide, heat it to 60°C and stir vigorously for 30min, then weigh 0.3g of octa(cobaltocene)-POSS and put it into the three-necked flask at 60°C. Stir vigorously for 24 hours to obtain a clear transparent sol, pour the transparent sol into a polytetrafluoroethylene film tray and place it for 24 hours, then move it into a 90°C oven to dry for 24 hours, then raise the temperature to 120°C for 24 hours, take it ...

Embodiment 2

[0028] To prepare a new type of organic-inorganic composite anion proton exchange membrane, the specific steps are as follows: first weigh 0.410g octaazidopropyl-POSS and 1.626g ethynyl cobaltocene, and add it to 60mL THF and 20mL H 2 Then add 0.722g of copper sulfate and 2.598g of L-sodium ascorbate to a three-necked flask of O at 0°C, react at room temperature for 24h, and evaporate the solvent to obtain octa(cobaltocene-based)-POSS, which is put into an oven for use. Then weigh 1.2g polyimide and put it into a three-necked flask containing 18mL dimethyl sulfoxide, heat it to 60°C and stir vigorously for 30min, then weigh 0.48g octa(cobaltocene-based)-POSS and add it to the three-necked flask at 60 Stir vigorously at ℃ for 24 hours to obtain a clear transparent sol. Pour the transparent sol into a polytetrafluoroethylene film tray and place it for 24 hours, then move it into a 90℃ oven to dry for 24 hours, then raise the temperature to 120℃ and place it for 24 hours, take it...

Embodiment 3

[0030] Prepare a new type of organic-inorganic composite anion proton exchange membrane, the specific steps are as follows: first weigh 0.350g octaazidopropyl-POSS and 1.388g ethynyl cobaltocene, and add it to 70mL THF and 23mL H 2 Then add 0.616g of copper sulfate and 2.218g of L-sodium ascorbate to a three-necked flask of O at 0°C, react at room temperature for 24h, and then evaporate the solvent to obtain octa(cobaltocene-based)-POSS, which is put into an oven for use. Then weigh 1.2g polybenzimidazole and put it into a three-necked flask containing 18mL dimethyl sulfoxide, heat it to 60°C and stir vigorously for 30min, then weigh 0.63g octa(cobaltocene-based)-POSS and add it to the three-necked flask at 60 Stir vigorously at ℃ for 24 hours to obtain a clear transparent sol. Pour the transparent sol into a polytetrafluoroethylene film tray and place it for 24 hours, then move it into a 90℃ oven to dry for 24 hours, then raise the temperature to 120℃ and place it for 24 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com