Flame-retardant antibacterial fabric and preparation method thereof

The technology of antibacterial fabric and antibacterial agent is applied in the field of flame retardant and antibacterial fabric and its preparation, which can solve the problems of high equipment requirements, high spinning cost, harm to human health, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

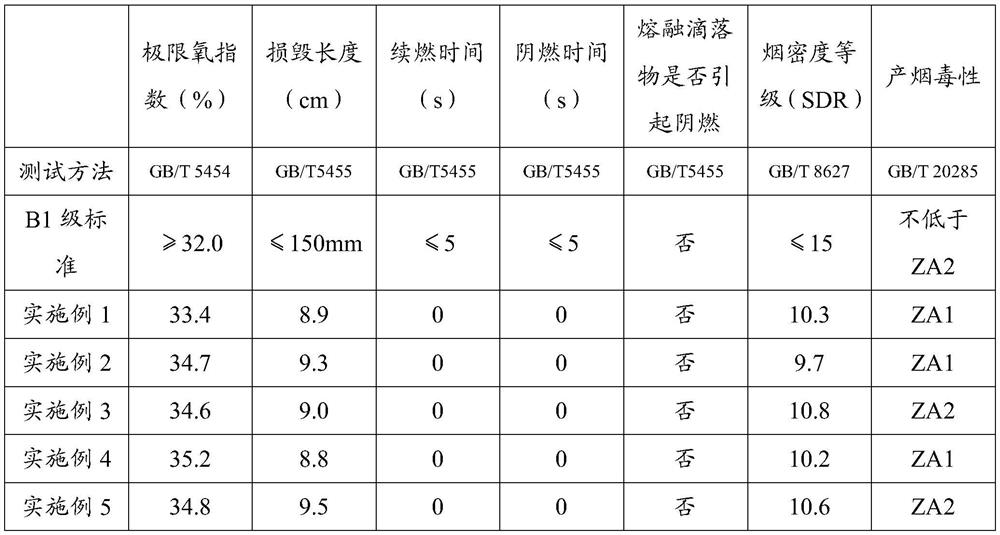

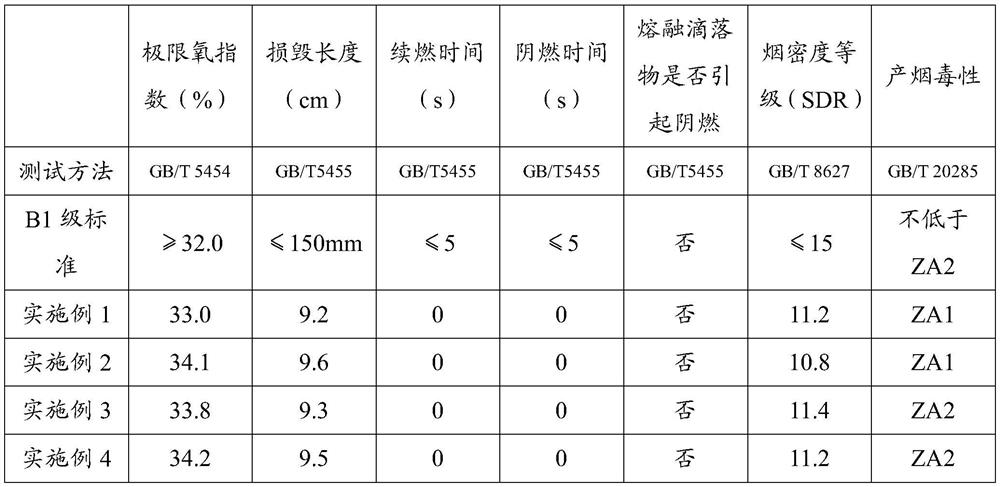

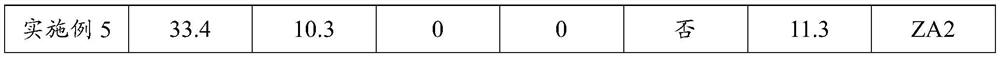

Examples

Embodiment 1

[0024] Mix the tencel fiber solution with a phosphorus-nitrogen composite flame retardant accounting for 1wt.% of the tencel fiber weight, and wet-spin to obtain a flame-retardant fiber; the phosphorus-nitrogen composite flame retardant includes by weight: triphenyl phosphate 60 parts of ester, 25 parts of ammonium polyphosphate, 26 parts of melamine cyanurate and 2 parts of zinc borate. The bamboo fiber solution is mixed with an antibacterial agent accounting for 0.8wt.% of the bamboo fiber weight, and the antibacterial fiber is obtained through wet spinning; the antibacterial agent includes 18 parts by weight of water-soluble chitin, 22 parts of citric acid, 12 parts of juniper oil and 30 parts of deionized water; wherein, the degree of deacetylation of the water-soluble chitin is 80%. Draw the flame-retardant fiber and antibacterial fiber at a weight ratio of 1:1, and then go through the roving, spun yarn, and two-for-one twisting processes in sequence to obtain a flame-ret...

Embodiment 2

[0026] Mix the modal fiber solution with a phosphorus-nitrogen composite flame retardant accounting for 1.3wt.% of the weight of the modal fiber, and wet-spin to obtain a flame-retardant fiber; the phosphorus-nitrogen composite flame retardant includes by weight: triphenyl phosphate 60 parts, ammonium polyphosphate 20 parts, melamine cyanurate 28 parts and zinc borate 2 parts. The chitin fiber solution is mixed with an antibacterial agent accounting for 1.4wt.% of the chitin fiber weight, and the antibacterial fiber is obtained through wet spinning; the antibacterial agent includes 20 parts by weight of water-soluble chitin, 26 parts of citric acid, 10 parts of juniper oil and 35 parts of deionized water; wherein, the degree of deacetylation of the water-soluble chitin is 95%. Draw the flame retardant fiber and antibacterial fiber at a weight ratio of 1:1, and then go through the roving, spun yarn, and two-for-one twisting processes in sequence to obtain a flame-retardant and ...

Embodiment 3

[0028] Mix the tencel fiber solution with a phosphorus-nitrogen composite flame retardant accounting for 1.6wt.% of the weight of the tencel fiber, and wet-spin to obtain a flame-retardant fiber; the phosphorus-nitrogen composite flame retardant includes by weight: triphosphate 50 parts of phenyl ester, 30 parts of ammonium polyphosphate, 28 parts of melamine cyanurate and 3 parts of zinc borate. The solution of chitin fiber and bamboo fiber is mixed with an antibacterial agent accounting for 1.2wt.% of the weight of chitin fiber and bamboo fiber, and the antibacterial fiber is obtained through wet spinning; the antibacterial agent includes water-soluble chitin by weight. 24 parts of citric acid, 28 parts of citric acid, 8 parts of juniper oil and 40 parts of deionized water; wherein, the degree of deacetylation of the water-soluble chitin is 85%. Draw the flame-retardant fiber and antibacterial fiber at a weight ratio of 2:1, and then go through roving, spun yarn, and two-for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com