Catalyst for hydrogenation conversion of Fischer-Tropsch synthetic wax and preparation method and application thereof

A Fischer-Tropsch synthetic wax and hydroconversion technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of easy secondary cracking, gasoline octane The problem of low value and high freezing point of diesel oil can reduce the selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

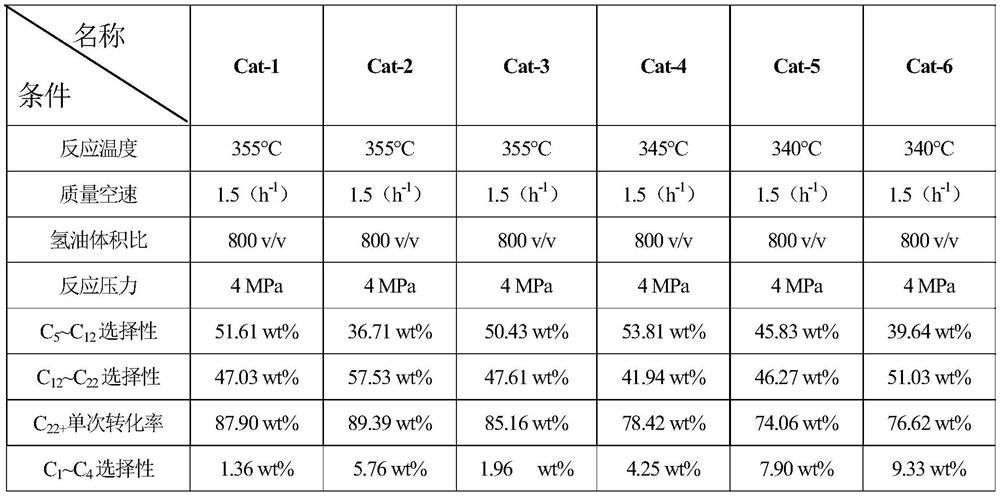

Examples

Embodiment 1

[0039] Weigh 714g of Type A Al 2 o 3 , mixed with water for beating and stirred rapidly for 4 hours, then added 150g of Y molecular sieve, adjusted the pH to 9 with ammonia water, added 272.55g of nickel nitrate pentahydrate after stirring for 2 hours, continued to stir for 2 hours and then stood still for 24 hours to obtain a mixture.

[0040] The mixture was placed in a closed reactor for hydrothermal treatment at 105°C and 1.4MPa, with a stirring rate of 300 rpm; after the hydrothermal treatment was completed, it was cooled, and after cooling, 50 g of SAPO-11 molecular sieves were added, stirred for 1 hour, filtered and washed, First dry at 70°C for 4 hours, then dry at 120°C for 12 hours, and then crush it into powder; add 1% scallop powder and dilute nitric acid diluted with concentrated nitric acid and water in a ratio of 1:70 to the powder, and then extrude. Dry at 80°C for 12h and then at 130°C for 6h, then calcinate at 500°C for 4h at a heating rate of 1.5°C / min to o...

Embodiment 2

[0043] Weigh 714g of Type A Al 2 o 3 , mixed with water for beating and stirred rapidly for 4 hours, then added 150g of Y molecular sieve, added 50g of SAPO-11 molecular sieve, and the stirring rate was 300 rpm; after stirring for 1 hour, filtered and washed, first dried at 70°C for 4h and then heated at 120°C Dry it under high temperature for 12 hours, and then crush it into powder; add 1% scallop powder and dilute nitric acid diluted with concentrated nitric acid and water according to the ratio of 1:70 to the powder, then extrude, and first dry at 80°C for 12h, and then at 130°C °C for 6 h, then calcined at 500 °C for 4 h at a heating rate of 1.5 °C / min to obtain the catalyst precursor.

[0044] Use the equal volume impregnation method to configure a solution containing 330g ammonium metatungstate and 272.55g nickel nitrate pentahydrate for impregnation, and let it stand for 16 hours, then dry it at 80°C for 4 hours, then dry it at 135°C for 12 hours, and then dry it at 60...

Embodiment 3

[0046] Under the same preparation conditions as in Example 1, 50 g of ZSM-22 molecular sieves were added after hydrothermal treatment and cooling to obtain catalyst Cat-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com