Method for separating and recovering titanium dioxide from metal tailings

A technology for titanium dioxide and metal tailings, applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., to achieve the effects of considerable economic benefits, improved recovery rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

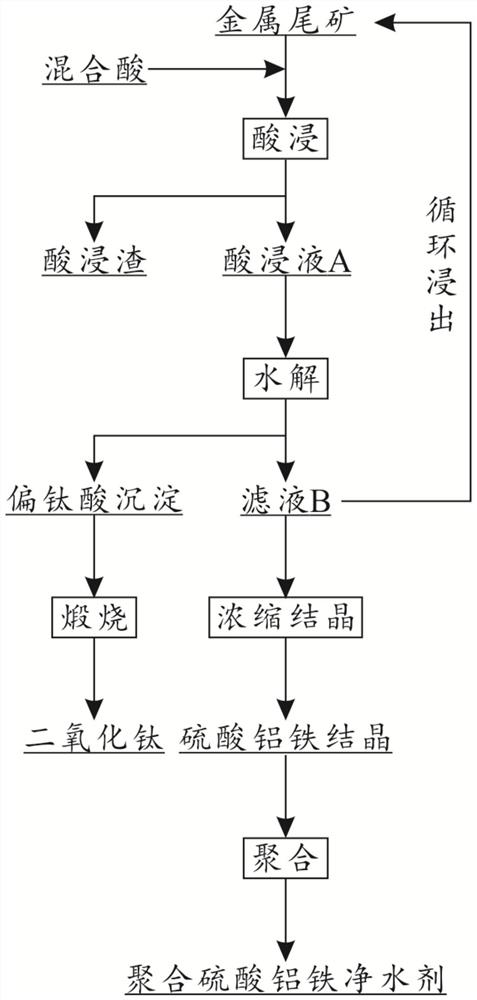

Method used

Image

Examples

Embodiment 1

[0052] The content of each component of the metal tailings of the present embodiment is as follows: SiO 2 —39.80%; Al 2 o 3 — 15.60%; Fe 2 o 3 —13.10%; CaO—10.3%; MgO—9.52%; CO 2 —5.95%; TiO 2 — 2.45%; Na 2 O—2.21%; P 2 o 5 —0.365%; K 2 O—0.309%; MnO—0.22%; SO 3 —0.102%.

[0053] The specific separation method is as follows:

[0054] Step 1: Mix metal tailings: mixed acid evenly according to the ratio of solid to liquid ratio of 1:10g / ml, stir for 30 minutes at a leaching temperature of 80°C, and filter through 400 mesh to obtain acid leaching solution A and acid leaching residue;

[0055] Wherein, the mixed acid is oxalic acid with a volume ratio of 5:1:5: citric acid: sulfuric acid mixing, the concentration of sulfuric acid is 4mol / L, the concentration of oxalic acid is 2mol / L, and the concentration of citric acid is 2mol / L;

[0056] Step 2, add 6mol / L sulfuric acid in the pickling solution A that step 1 obtains, to the H in the pickling solution A + The molar c...

Embodiment 2

[0063] The metal tailings of the present embodiment are the metal tailings in embodiment 1, and the specific separation method is as follows:

[0064] Step 1: Mix metal tailings: mixed acid evenly according to the ratio of solid to liquid ratio of 1:12g / ml, stir for 40min at a leaching temperature of 90°C, and filter through 400 mesh to obtain acid leaching solution A and acid leaching residue;

[0065] Wherein, the mixed acid is oxalic acid with a volume ratio of 6:1:5: citric acid: sulfuric acid mixing, the concentration of sulfuric acid is 6mol / L, the concentration of oxalic acid is 3mol / L, and the concentration of citric acid is 2mol / L;

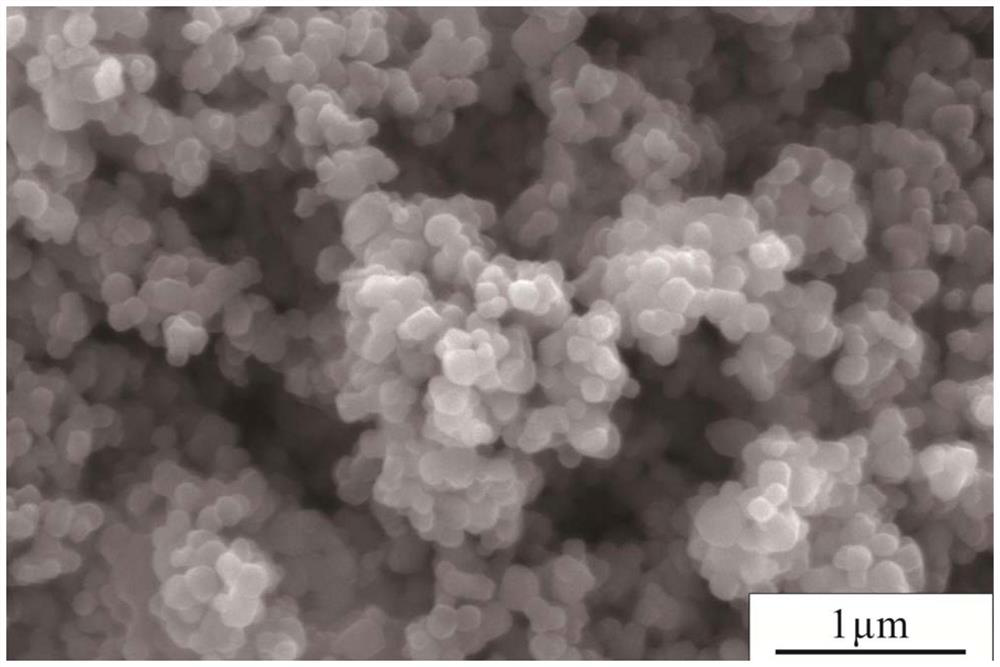

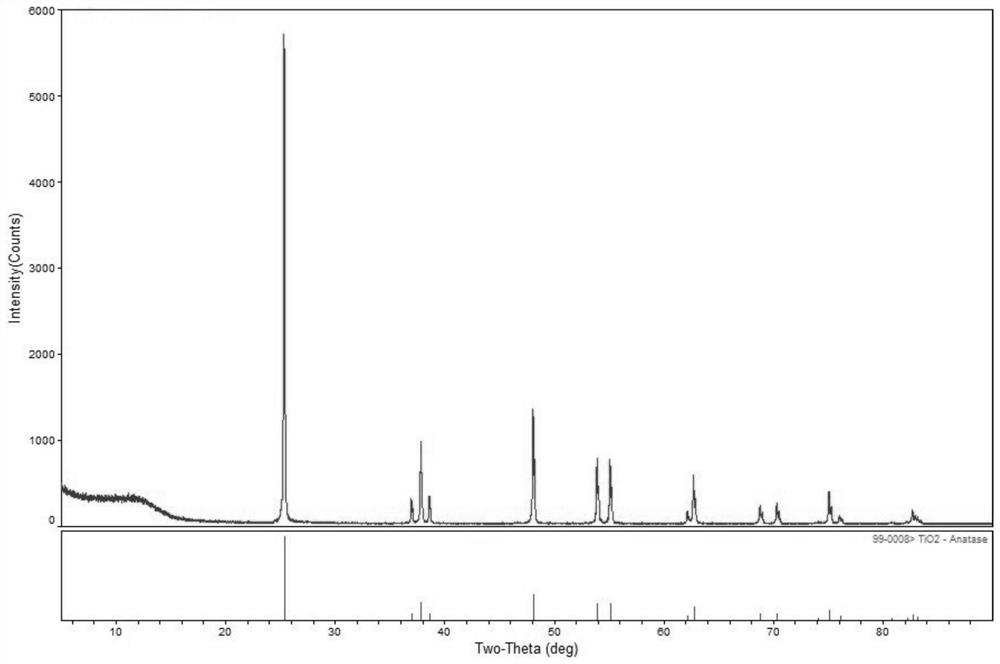

[0066] Step 2, add 6mol / L sulfuric acid in the pickling solution A that step 1 obtains, to the H in the pickling solution A + The molar concentration ratio to Ti ions is 1:1, hydrolyzed at 90°C for 4 hours, filtered through 400 mesh to obtain precipitate and filtrate B, and then dried and calcined at 600°C for 5 hours to obtain titanium d...

Embodiment 3

[0073] The metal tailings of the present embodiment are the metal tailings in embodiment 1, and the specific separation method is as follows:

[0074] Step 1: Mix metal tailings: mixed acid evenly according to the ratio of solid to liquid ratio of 1:10g / ml, stir for 30min at a leaching temperature of 90°C, and filter through 400 mesh to obtain acid leaching solution A and acid leaching residue;

[0075] Wherein, the mixed acid is oxalic acid with a volume ratio of 8:1:10: citric acid: sulfuric acid mixed, the concentration of sulfuric acid is 4mol / L, the concentration of oxalic acid is 3mol / L, and the concentration of citric acid is 3mol / L;

[0076] Step 2, add 6mol / L sulfuric acid in the pickling solution A that step 1 obtains, to the H in the pickling solution A + The molar concentration ratio to Ti ions is 1:1, hydrolyzed at 90°C for 4 hours, filtered through 400 mesh to obtain precipitate and filtrate B, and then dried and calcined at 450°C for 6 hours to obtain titanium d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com