A kind of high temperature resistant and high compatibility trapezoidal silicone resin and its preparation method and application

A compatible and high-temperature-resistant technology, applied in adhesives and other directions, can solve the problems of poor controllability of molecular structure and achieve good reaction specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

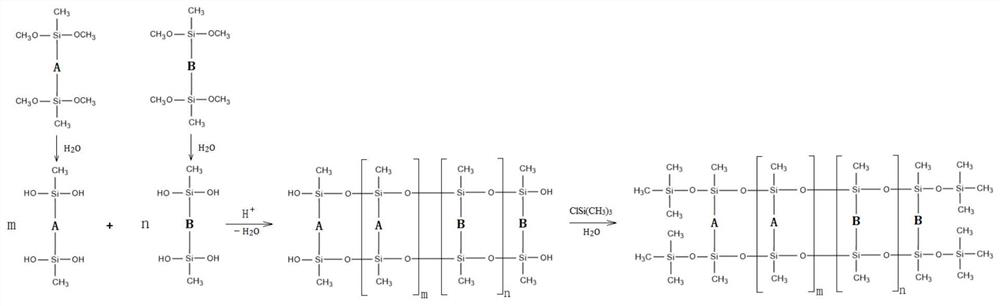

Method used

Image

Examples

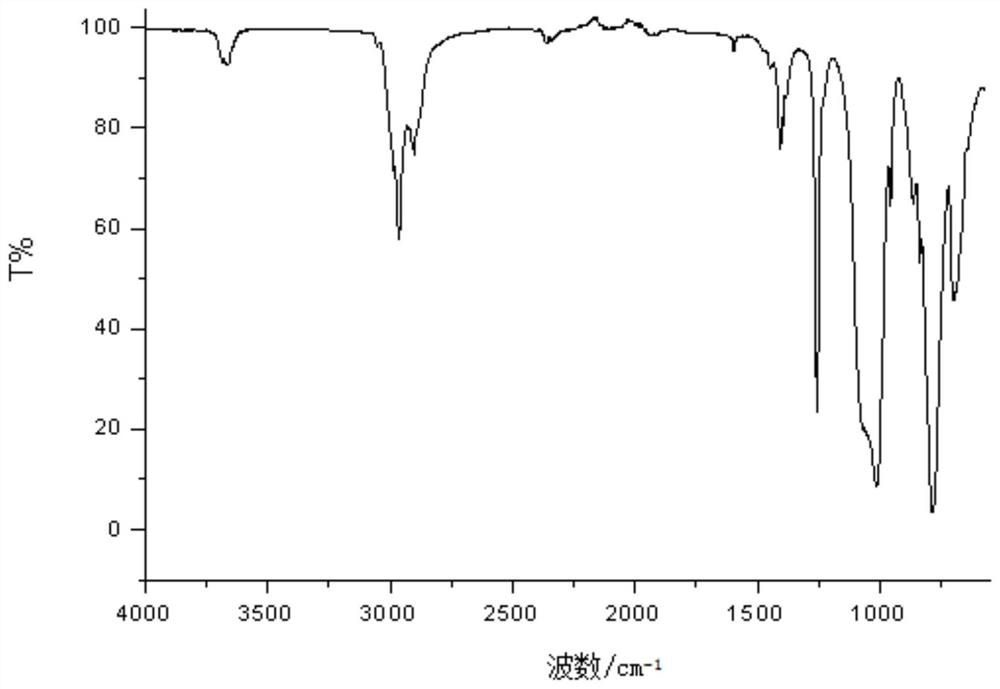

Embodiment 1

[0045] The preparation method of a high temperature resistant and high compatibility trapezoidal silicone resin of the present embodiment, the specific preparation steps are as follows:

[0046] (1) Preparation of Methylpolysiloxane Ladder Prepolymer:

[0047] In a four-necked flask equipped with a constant-pressure dropping funnel, a reflux condenser, a thermometer and an electric mixer, add vinyl-terminated tetramethyldisiloxane (vinyl double-capped head, a=0, M n =186)) and isopropanol solvent, stirring and dissolving uniformly, heating and warming up to 80 ℃ under nitrogen protection, adding the chloroplatinic acid catalyst of calculated amount to the four-necked flask, making the platinum content in the system 25ppm, opening the constant pressure subsequently The dropping funnel slowly added methyldimethoxysilane (the molar ratio of vinyl to hydrogen was 1:1.1) into the four-necked flask, and the temperature was controlled to be 80°C to carry out reflux reaction for 2h. ...

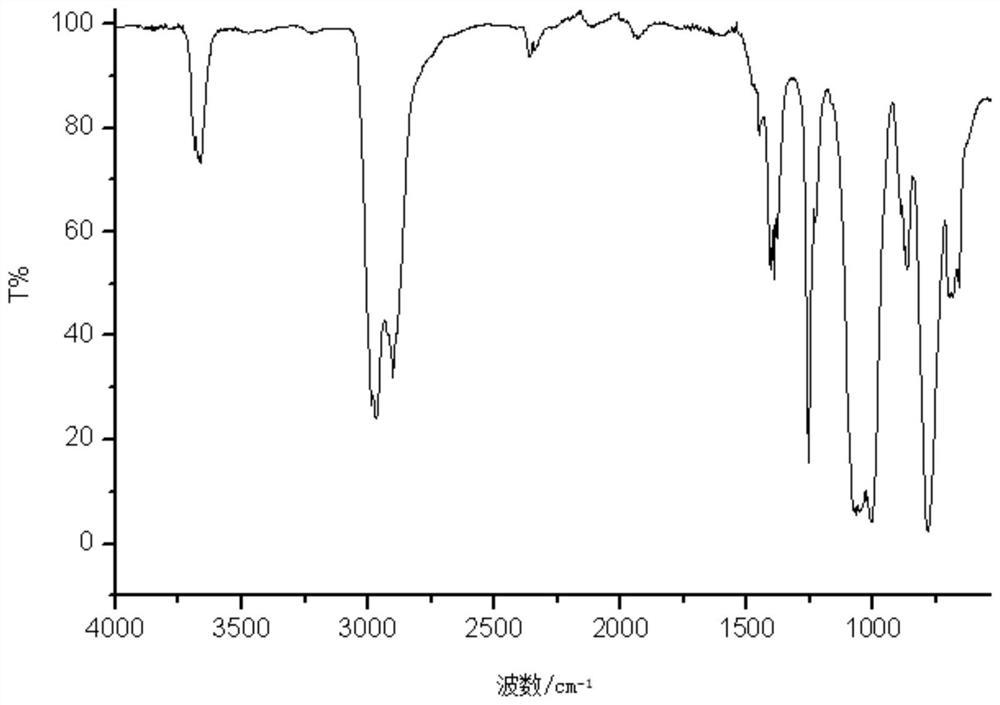

Embodiment 2

[0054] The preparation method of a high temperature resistant and high compatibility trapezoidal silicone resin of the present embodiment, the specific preparation steps are as follows:

[0055] (1) Preparation of Methylpolysiloxane Ladder Prepolymer:

[0056] In a four-necked flask equipped with a constant-pressure dropping funnel, a reflux condenser, a thermometer and an electric mixer, add vinyl-terminated polydimethylsiloxane (a=8, average molecular weight M n 800) and ethylene glycol monoethyl ether solvent, stir and dissolve evenly, heat up to 80°C under nitrogen protection, add the calculated amount of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane Alkyl platinum (0) catalyst is placed in a four-necked flask, so that the platinum content in the system is 10ppm, then the constant pressure dropping funnel is opened and methyldimethoxysilane (by the mol ratio of vinyl and hydrogen is 1:1.05) ) was slowly added to the four-necked flask, and the control temperature was 100°C to ...

Embodiment 3

[0062] The preparation method of a high temperature resistant and high compatibility trapezoidal silicone resin of the present embodiment, the specific preparation steps are as follows:

[0063] (1) Preparation of Methylpolysiloxane Ladder Prepolymer:

[0064] In a four-necked flask equipped with a constant-pressure dropping funnel, a reflux condenser, a thermometer and an electric mixer, add vinyl-terminated polydimethylsiloxane (a=15, average molecular weight M n 1300), and a mixed solvent of isopropanol and ethylene glycol monoethyl ether, stir and dissolve evenly, heat up to 80°C under nitrogen protection, add the calculated amount of 1,3-divinyl-1,1,3,3- The tetramethyldisiloxane platinum (0) catalyst was placed in a four-necked bottle, so that the platinum content in the system was 50 ppm, then the constant pressure dropping funnel was opened and methyldimethoxysilane (by moles of vinyl and hydrogen) was added. The ratio is 1:1.1 feeding) slowly added to the four-necked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com