Heat-resistant flame-retardant impact-resistant polyvinyl chloride/polylactic acid alloy and preparation method thereof

A technology of polyvinyl chloride and polylactic acid, which is applied in the field of heat-resistant, flame-retardant and impact-resistant polyvinyl chloride/polylactic acid alloy and its preparation, can solve the problems of improvement of flame retardancy and impact performance, different components and principles, Problems such as limited application range, to achieve the effect of good melt fluidity, high mechanical properties, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

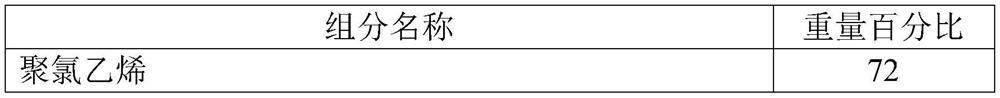

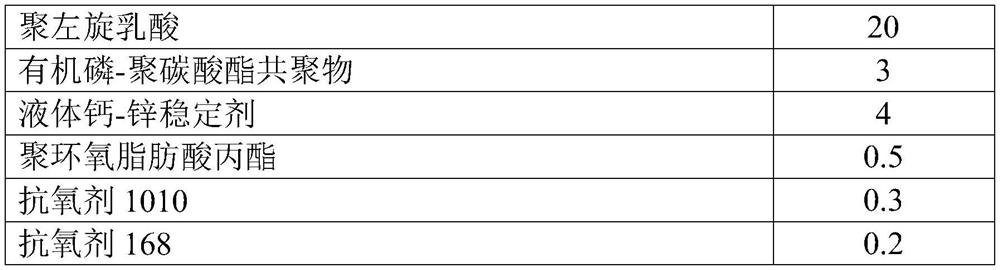

[0032] A heat-resistant, flame-retardant and impact-resistant polyvinyl chloride / polylactic acid alloy, the plastic alloy comprises the following components by weight percentage:

[0033]

[0034]

[0035]The polylactic acid was dried in a dew point dryer. Set the drying temperature to 90°C, the dew point temperature to -60°C, the stirring speed of the hopper to 10rpm, and the drying time to 4h. The organophosphorus-polycarbonate copolymer is placed in a dew point dryer for drying. Set the drying temperature to 110°C, the dew point temperature to -60°C, the stirring speed of the hopper to 10 rpm, and the drying time to 6 hours. Make sure the moisture content of the above materials is below 200ppm.

[0036] Put polyvinyl chloride in a vacuum high-speed mixer, set the stirring speed of the mixer to 400rpm, the stirring temperature at 105°C, and the vacuum degree -0.1Mpa, slowly add liquid calcium-zinc stabilizer and antioxidant, and stir fully for 10min to ensure that th...

Embodiment 2

[0041] A heat-resistant, flame-retardant and impact-resistant polyvinyl chloride / polylactic acid alloy, the plastic alloy comprises the following components by weight percentage:

[0042] component name weight percentage PVC 20 poly d-lactic acid 72 Organophosphorus-polycarbonate copolymer 5 Solid Calcium-Zinc Stabilizer 2 polyepoxypropyl fatty acid ester 0.5 Antioxidant 1010 0.3 Antioxidant 168 0.2

[0043] The polylactic acid was dried in a dew point dryer. Set the drying temperature to 90°C, the dew point temperature to -60°C, the stirring speed of the hopper to 10rpm, and the drying time to 4h. The organophosphorus-polycarbonate copolymer is placed in a dew point dryer for drying. Set the drying temperature to 110°C, the dew point temperature to -60°C, the stirring speed of the hopper to 10 rpm, and the drying time to 6 hours. Make sure the moisture content of the above materials is below 200ppm.

[0044] Put poly...

Embodiment 3

[0049] A heat-resistant, flame-retardant and impact-resistant polyvinyl chloride / polylactic acid alloy, the plastic alloy comprises the following components by weight percentage:

[0050] component name weight percentage PVC 46 poly-L-lactic acid 46 Organophosphorus-polycarbonate copolymer 4 Solid Calcium-Zinc Stabilizer 3.5 polyepoxypropyl fatty acid ester 1 Antioxidant 1010 0.3 Antioxidant 168 0.2

[0051] The polylactic acid was dried in a dew point dryer. Set the drying temperature to 90°C, the dew point temperature to -60°C, the stirring speed of the hopper to 10rpm, and the drying time to 4h. The organophosphorus-polycarbonate copolymer is placed in a dew point dryer for drying. Set the drying temperature to 110°C, the dew point temperature to -60°C, the stirring speed of the hopper to 10 rpm, and the drying time to 6 hours. Make sure the moisture content of the above materials is below 200ppm.

[0052] Put poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com