Novel high-refractive-index coating mixed material and production process thereof

A technology of high refractive index and mixed materials, which is applied in the field of new high refractive index coating mixed materials and its production process, can solve the problems of low production efficiency, high cost of production materials, large amount of outgassing, etc., and achieve improved yield and point defects The effect of reducing and outgassing is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

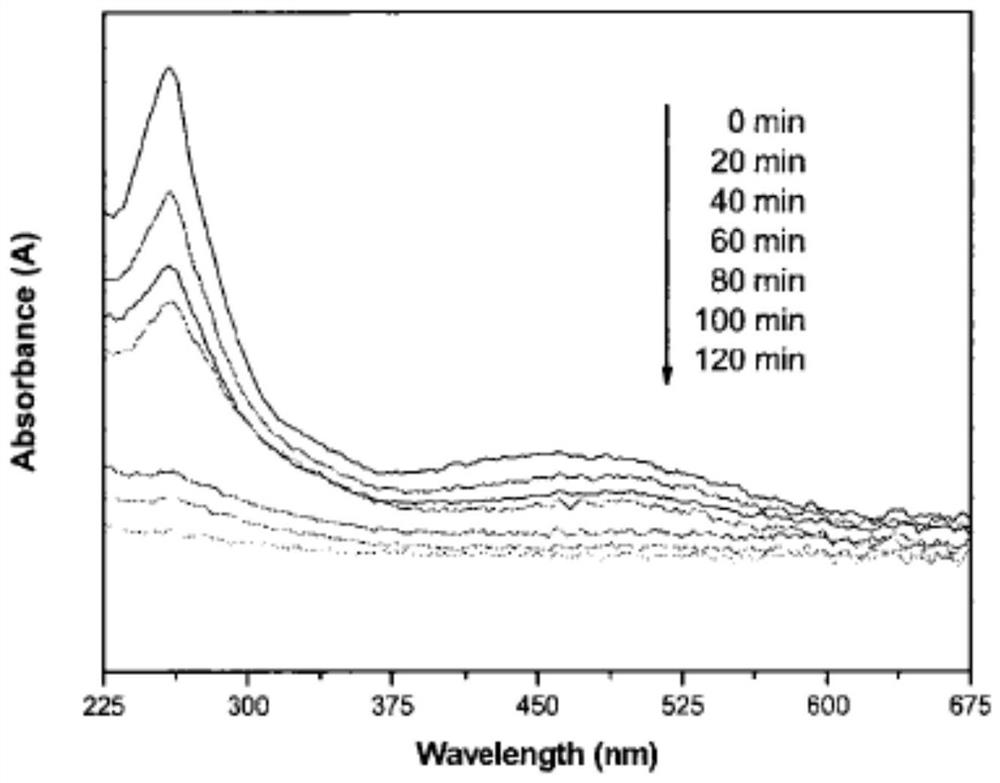

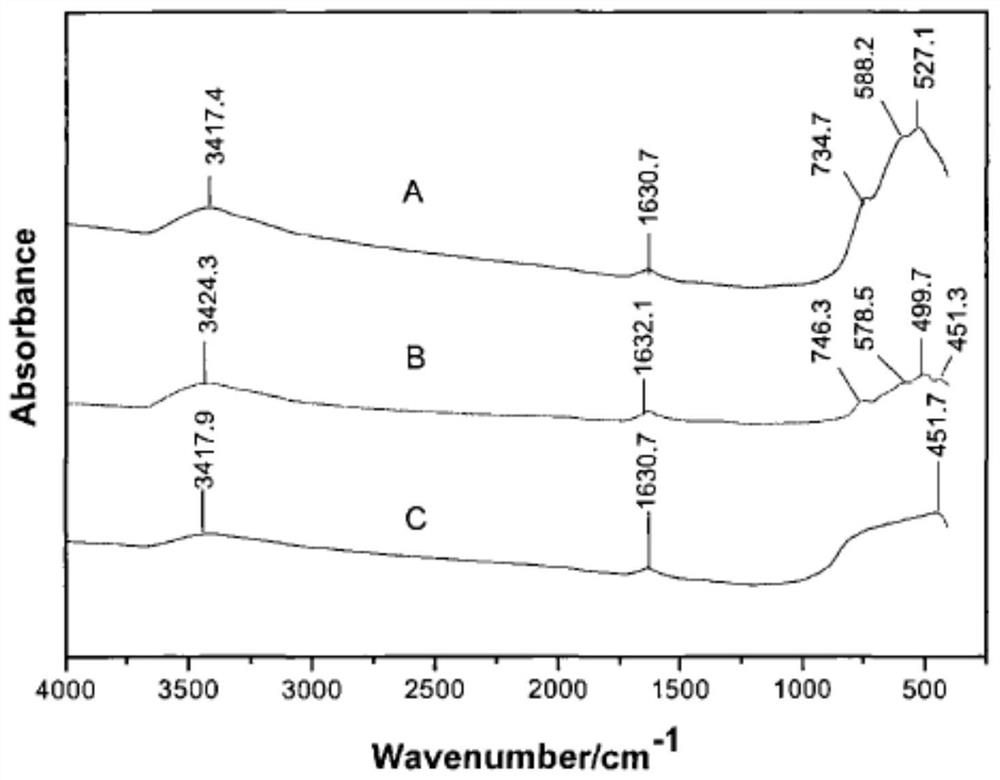

[0032] Such as Figure 1-3 As shown, a new type of high refractive index coating hybrid material, including optical coating material, said optical coating material is composed of zirconia, titanium oxide and other additives, said zirconia includes ZrO2 , the titanium oxide includes TiO 2 , said its additives include titanium powder, because titanium oxide and zirconium oxide cannot reach 100% purity, containing impurities such as Co, Mn, Ni, Cu, Al, Pb, Fe, and Si, these impurities are in the form of oxides It exists in the material, which affects the refractive index of the film. For example, the refractive index of aluminum oxide is 1.7, and the projection wavelength range is between 170-6500nm. It is necessary to add other additives to reduce and remove impurities to avoid the impact of impurities on the film material. The ZrO 2 50-99.5wt%, TiO 2 0.5-50wt% and metal titanium powder 0-20wt%, titanium oxide and zirconium oxide have strong light absorption ability even in th...

Embodiment 2

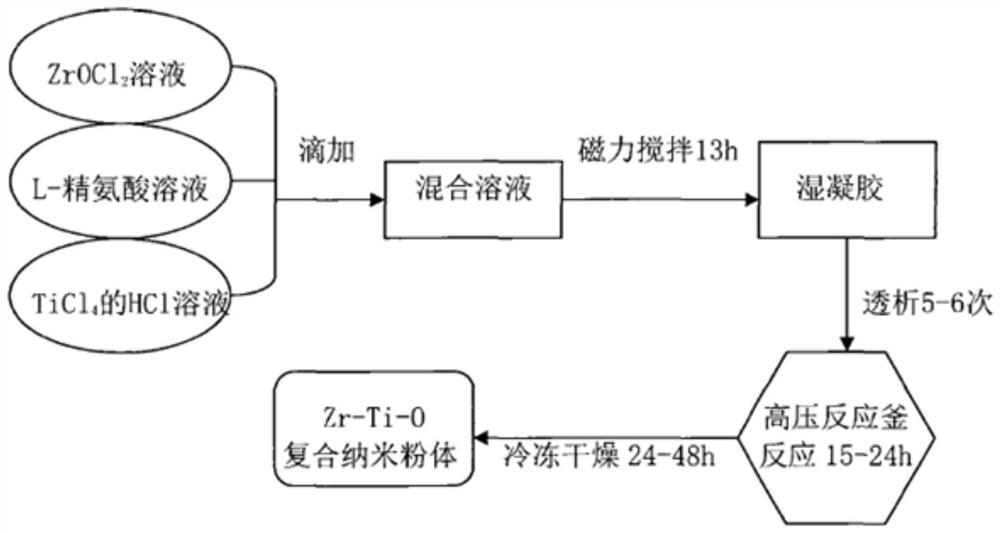

[0034] Such as figure 2 and image 3 As shown, the production process of a new type of high refractive index coating hybrid material includes the following steps:

[0035] Sp1: Put the obtained transparent solution as the precursor of the hydrothermal reaction into the activated dialysis bag for 5-6 times of dialysis, and the external solution is ionic water until the pH of the solution is close to neutral, and remove an appropriate amount of silver nitrate solution to detect the residual Chloride ions;

[0036] Sp2: Put the dialyzed gel in a 50mL pair of autoclave, put it in a blast oven at 170-230°C for 15-24h, and prepare Zr-Ti-O composite nanocrystals by hydrothermal reaction;

[0037] Sp3: After freezing the obtained product at a low temperature of -20°C for 24-48 hours, place it in a freeze dryer for vacuum freeze-drying to obtain dispersed Zr-Ti-O composite nanopowder;

[0038] Sp4: granulation, put the Zr-Ti-O composite nanopowder into the swing granulator, add the...

Embodiment 3

[0042] When configuring the pre-solution, the three raw materials of zirconia, titanium oxide and metal titanium powder can be mixed, and then the mixed raw materials can be put into the 3D mixer, and at the same time according to the TiO 2 50-100w%, 20-50w% zirconia, 0-20w% titanium metal powder, put into the auxiliary group of grinding balls with different diameters to mix, mix at a speed of 5-30r / min for 2-5 hours, and then configure Good ZrOCl 2 solution and prepared TiCl 4 The hydrochloric acid solution is mixed in a ratio of 1:4, and then slowly dripped into the configured L-arginine solution. With the addition of the precipitant, it is mixed with the raw materials in the above-mentioned 3D mixer in the reaction vessel, and magnetically The stirrer was stirred at room temperature for 13 hours, and the stirring was stopped after the reaction was complete, and the obtained stock solution was subjected to gelation treatment.

[0043] After the gel treatment is completed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com