A high-strength anti-blue light, anti-ultraviolet PC lens and preparation method thereof

A high-strength, anti-blue light technology, applied in optics, optical components, instruments, etc., can solve the problems of high thermoforming temperature of PC resin, ultraviolet exposure, and decomposition of absorbents, achieve good mechanical properties, simple preparation process, and solve chromatic aberration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

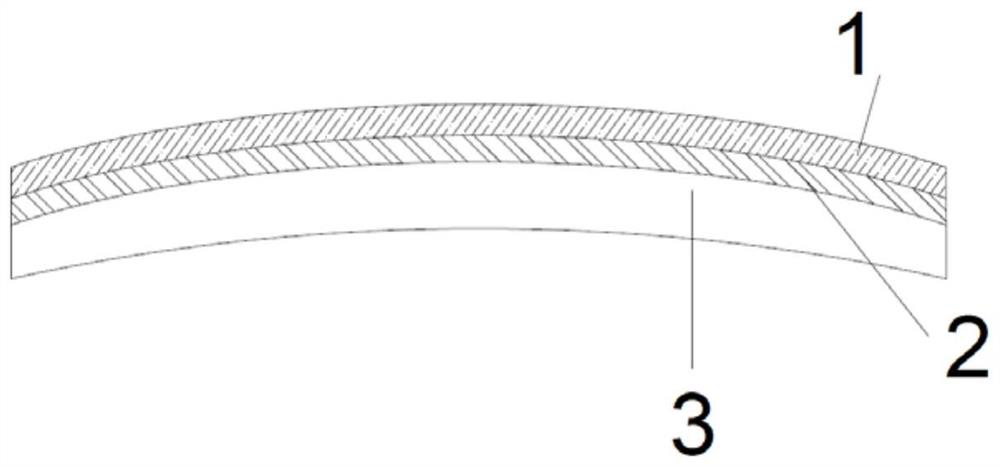

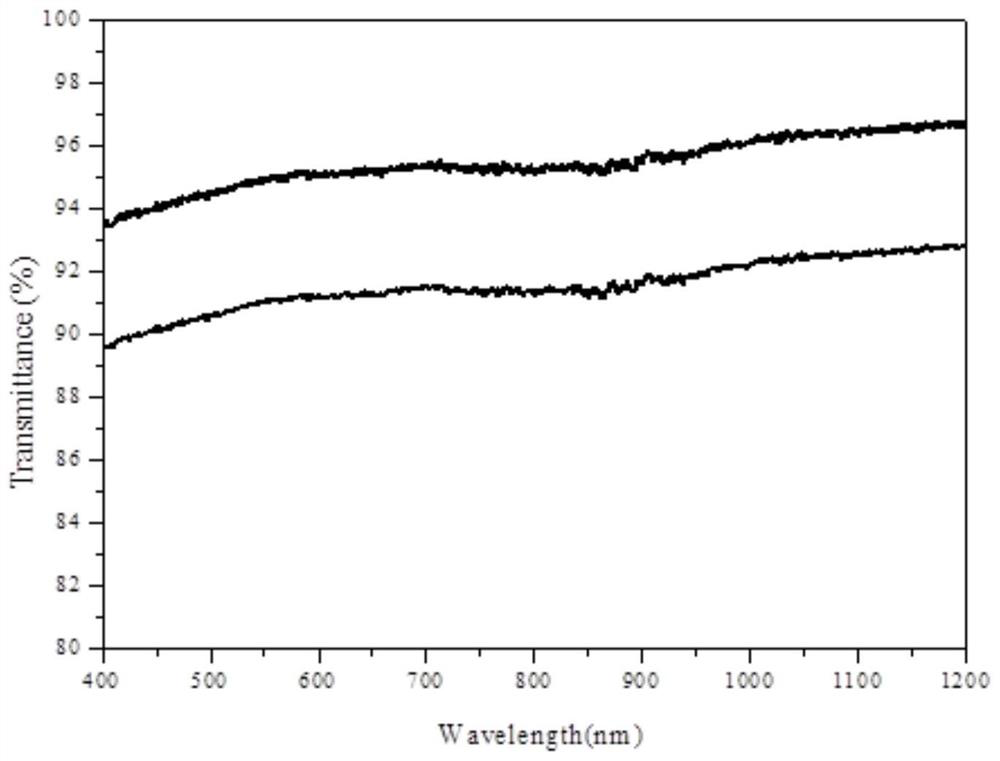

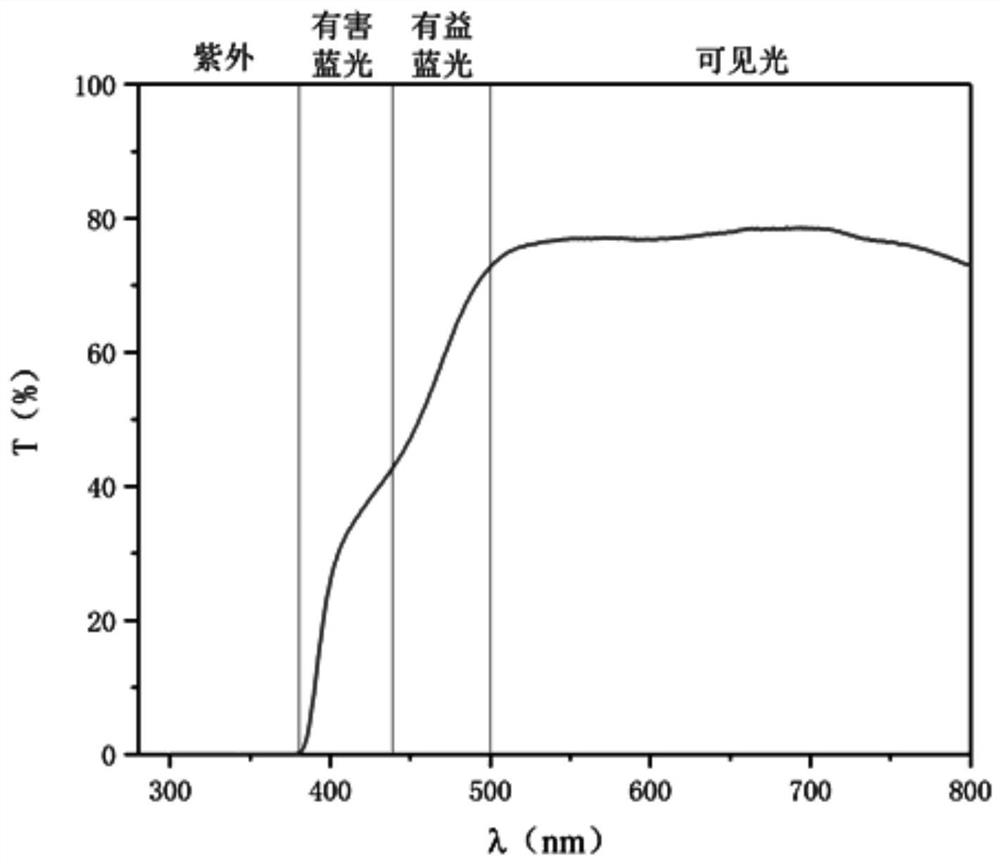

[0037] Embodiment 1, see attached Figure 1~3 , a method for preparing high-strength anti-blue light and anti-ultraviolet PC lenses, using PC resin as the base material, selecting blue light absorbers and ultraviolet light absorbers with good compatibility, high temperature resistance and excellent performance, through injection molding processing process, prepared high-strength anti-blue light and anti-ultraviolet PC lenses with excellent protection performance and good durability, as shown in Figure 1, the high-strength anti-blue light and anti-ultraviolet PC lenses have a three-layer structure, including PC lenses 3, Harden Coating 2 and AR Coating 1. Its specific production process is as follows:

[0038] (1) Put the optical-grade PC pellets into a drying oven for dehydration and drying at 160°C for 10 hours to completely remove moisture.

[0039](2) the weight fraction is (1.5%) ultraviolet light absorber, the weight fraction is (1%) blue light absorber and the weight f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com