Preparation method of propolis extract of skin care product

A technology of propolis extract and skin care product, applied in the field of preparation of skin care product propolis extract, can solve problems such as temperature increase, viscosity increase, adverse effect of grinding effect, etc., to increase contact area, increase heat dissipation effect, improve The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

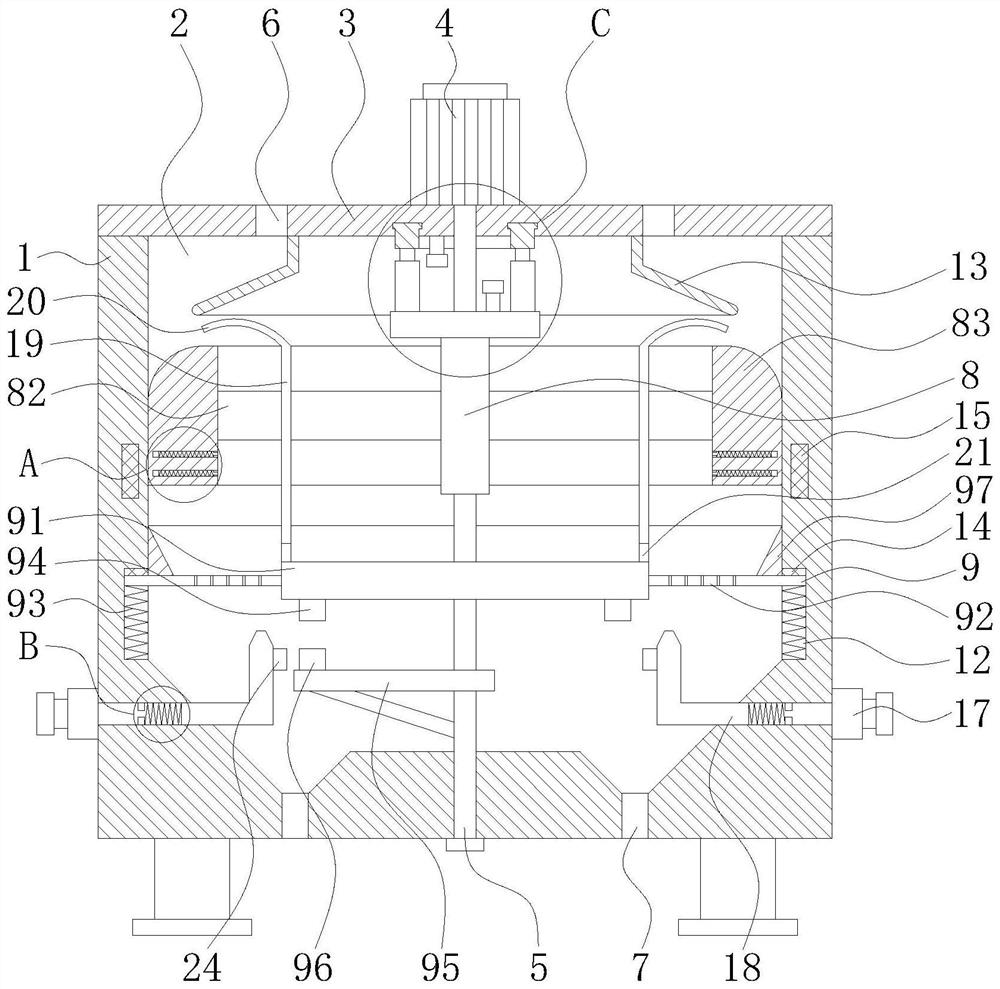

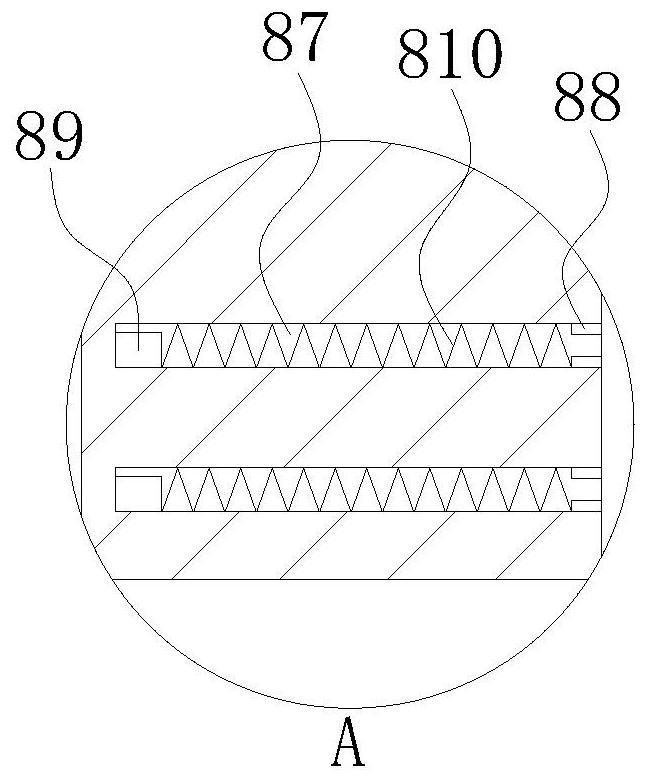

[0032] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

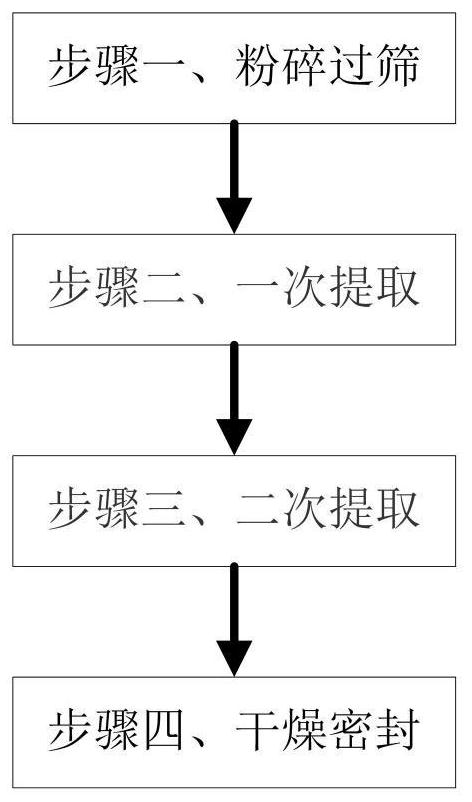

[0033] like figure 1 As shown, the present embodiment provides a method for preparing a skin care product propolis extract, comprising the following steps:

[0034] Step 1: Pulverize and sieve: remove impurities from the raw propolis and freeze it into blocks. The lump propolis is crushed and sieved to obtain propolis powder.

[0035] Step 2, primary extraction: add n-hexane, ethyl acetate and ethanol mixed solution to the propolis powder prepared in step 1, and filter after ultrasonic treatment to obtain primary filter residue and primary filtrate. The primary extract was obtained by concentrating the filtrate under reduced pressure.

[0036] Step 3, secondary extraction: add ethanol aqueous solution to the primary filter residue obtained in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com