Special room temperature cured epoxy resin A/B adhesive for mutual inductor body bonding

An epoxy resin, room temperature curing technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve problems such as coil waste, poor high-temperature bonding performance, and bonding point breakage, so as to facilitate production operations, Good fluidity, high thixotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A special room temperature curing epoxy resin A / B glue for bonding transformer bodies, characterized in that it includes two components AB, and the specific components and parts by weight ratio of the two components AB are as follows:

[0038] 1) Group A is divided into:

[0039] Liquid bisphenol A epoxy resin 188 240 parts

[0040] Novolak epoxy resin F-51 260 parts

[0041] Four functional epoxy resin AG-80 100 parts

[0042] 50 parts of 1,4-butanediol glycidyl ether

[0043] Fumed silica H-18 50 parts

[0044] 200 parts of 1000 mesh calcium carbonate

[0045] 100 parts of 1000 mesh quartz sand

[0046] 2) Group B is divided into:

[0047] 250 parts of liquid polyamide

[0048] 200 parts of isophorone diamine

[0049] 50 parts m-phenylenediamine

[0050] Polyetheramine 230 50 parts

[0051] Fumed silica A200 50 parts

[0052] 200 parts of 1000 mesh calcium carbonate

[0053] 200 parts of 1000 mesh quartz sand

[0054] Prepared by the following preparation...

Embodiment 2

[0060] A special room temperature curing epoxy resin A / B glue for bonding transformer bodies, characterized in that it includes two components AB, and the specific components and parts by weight ratio of the two components AB are as follows:

[0061] 1) Group A is divided into:

[0062] Liquid bisphenol A epoxy resin 188 240 parts

[0063] Novolak epoxy resin F-51 260 parts

[0064] Four functional epoxy resin AG-80 80 parts

[0065] 50 parts of 1,4-butanediol glycidyl ether

[0066] Organosilane coupling agent KH-560 20 parts

[0067] Fumed silica H-18 50 parts

[0068] 200 parts of 1000 mesh calcium carbonate

[0069] 100 parts of 1000 mesh quartz sand

[0070] 2) Group B is divided into:

[0071] 250 parts of liquid polyamide

[0072] 200 parts of isophorone diamine

[0073] 50 parts m-phenylenediamine

[0074] Polyetheramine 230 50 parts

[0075] Fumed silica A200 50 parts

[0076] 200 parts of 1000 mesh calcium carbonate

[0077] 200 parts of 1000 mesh quartz...

Embodiment 3

[0080] A special room temperature curing epoxy resin A / B glue for bonding transformer bodies, characterized in that it includes two components AB, and the specific components and parts by weight ratio of the two components AB are as follows:

[0081] 1) Group A is divided into:

[0082]Liquid bisphenol A epoxy resin 188 240 parts

[0083] Novolak epoxy resin F-51 260 parts

[0084] 50 parts of 1,4-butanediol glycidyl ether

[0085] Fumed silica H-18 50 parts

[0086] 200 parts of 1000 mesh calcium carbonate

[0087] 200 parts of 1000 mesh quartz sand

[0088] 2) Group B is divided into:

[0089] 250 parts of liquid polyamide

[0090] 200 parts of isophorone diamine

[0091] 50 parts m-phenylenediamine

[0092] Polyetheramine 230 50 parts

[0093] Fumed silica A200 50 parts

[0094] 200 parts of 1000 mesh calcium carbonate

[0095] 200 parts of 100 mesh quartz sand

[0096] The preparation method of embodiment 3 is identical with embodiment 1.

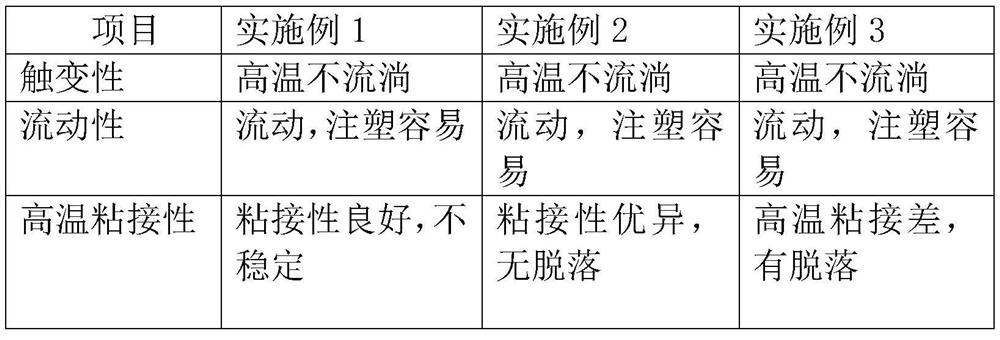

[0097] By using hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com