Lithium supplementing sustained-release capsule, electrolyte thereof and lithium ion battery

A technology for slow-release capsules and electrolytes, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrolytes, etc., can solve problems such as reducing conduction efficiency and battery performance damage, improving cycle performance, improving service life, and improving compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

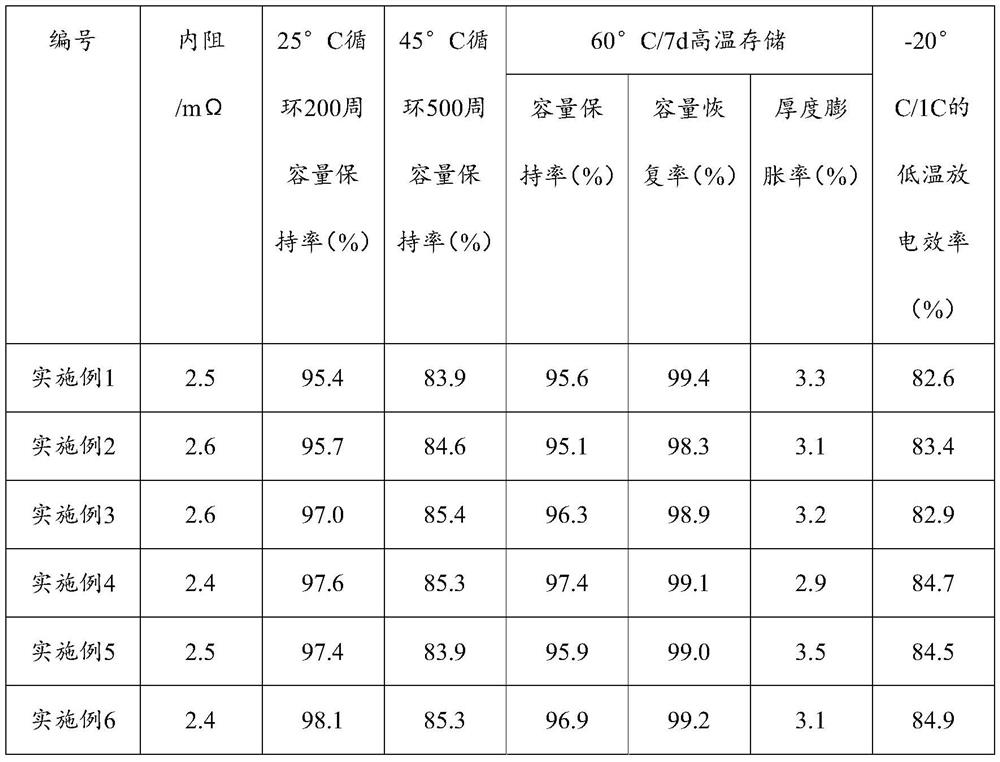

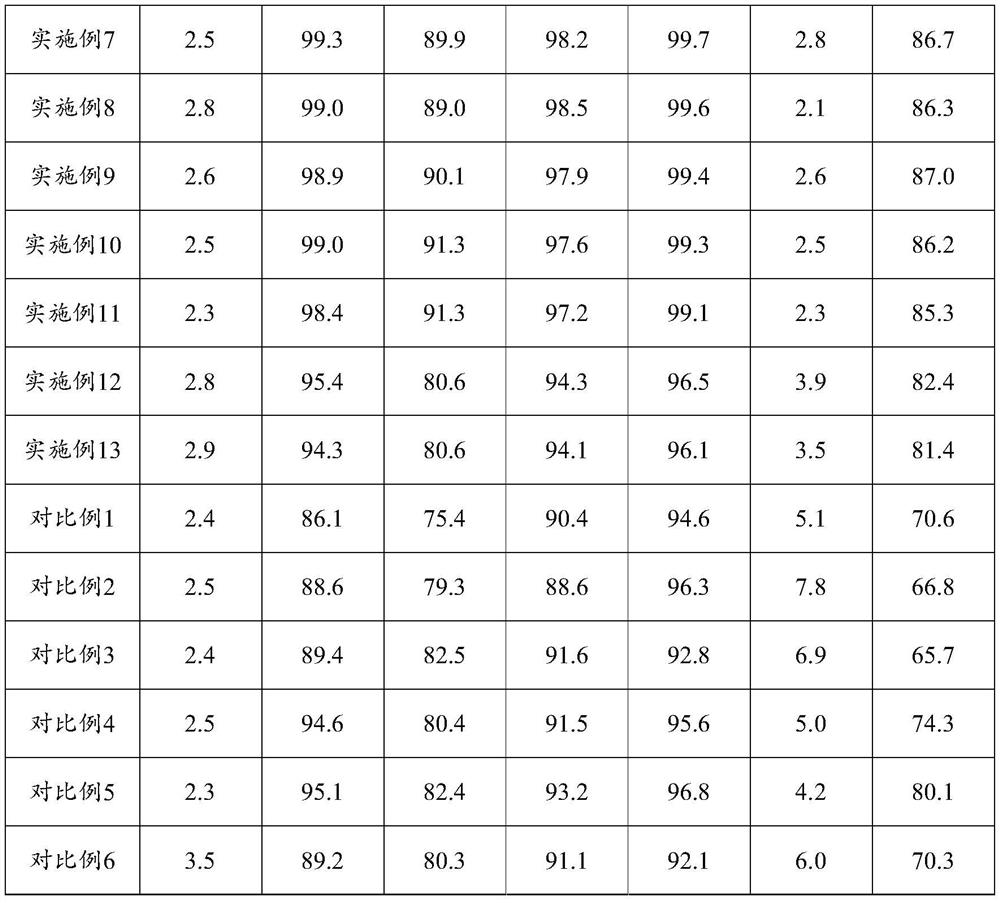

Examples

preparation example Construction

[0027]The present invention provides a method of preparing a bonded lithium sustained release capsule according to the above scheme, including the following steps:

[0028]1) Mix the amino resin monomer, formaldehyde, gelatin and water, adjust the pH of the obtained mixture to 6.0-8.5, heat it to 40-70°C and keep it for 20-60 minutes to obtain gelatin modified amino resin prepolymer Solution

[0029]2) Mix the new lithium salt solution with the gelatin-modified amino resin prepolymer solution of step 1), raise the temperature to 40-60°C, adjust the pH value to 3-5, and sequentially add the resulting pH-adjusted mixture After stirring and standing, the gelatin-modified amino resin prepolymer solution is coated on the surface of the lithium salt solution to obtain a first-layer coated capsule;

[0030]3) Mix the acrylate monomer, initiator, and crosslinking agent with the first-layer coated capsule of step 2), and raise the temperature to 60-80° C. to react for 2-5 hours to obtain a lithium-su...

Embodiment 1

[0043]Add 0.36g of gelatin, 3.6g of melamine, 4.0g of 37% formaldehyde and 25g of water into a 250mL three-necked flask, adjust the pH to 8.5 with sodium hydroxide solution, and then heat to 70℃, the reaction solution is clarified and kept warm After reacting for 20 minutes, the gelatin modified resin prepolymer solution was prepared, which was cooled to room temperature for later use.

[0044]Use ethylene glycol dimethyl ether to prepare lithium difluorophosphate into a lithium difluorophosphate solution with a mass concentration of 30%, then add it to a 100mL three-necked flask equipped with a thermometer, agitator and reflux condenser, and add the gelatin prepared above Modified resin prepolymer solution (the mass of melamine used to prepare the gelatin modified resin prepolymer solution is 20% of the mass of the lithium difluorophosphate solution), add hydrochloric acid at 50°C, adjust the pH to 3.5, and use 100r / min Stir for 3h at the rotating speed of, and let stand for 1h. The g...

Embodiment 2

[0047]Add 0.57g of gelatin, 3.6g of urea, 0.54g of 37% formaldehyde and 25g of water into a 250mL three-necked flask, adjust the pH to 6.0 with sodium hydroxide solution, then heat to 40℃, and keep the reaction solution clarified. After reacting for 60 minutes, the gelatin modified resin prepolymer solution was prepared, and it was cooled to room temperature for later use.

[0048]Use ethylene glycol dimethyl ether to prepare lithium bisfluorosulfonimide into a solution of lithium bisfluorosulfonimide with a mass concentration of 30%, and then add it to a 100mL three-necked flask equipped with a thermometer, agitator and reflux condenser. Add the gelatin modified resin prepolymer solution prepared above (the mass of urea used to prepare the gelatin modified resin prepolymer solution is 70% of the mass of the lithium difluorophosphate solution), add hydrochloric acid at 40°C, and adjust the pH to 5. Stir at a speed of 200r / min for 2.5h and let it stand for 1h. The gelatin modified resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com