Production equipment for graphite product with gorgeous surface colors

A technology for graphite products and production equipment, applied in the direction of manufacturing tools, material forming presses, punching machines, etc., can solve the problem of inability to apply graphite products dyeing, etc., and achieve the effect of ingenious design of processing mechanism, guaranteed strength, and ingenious structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

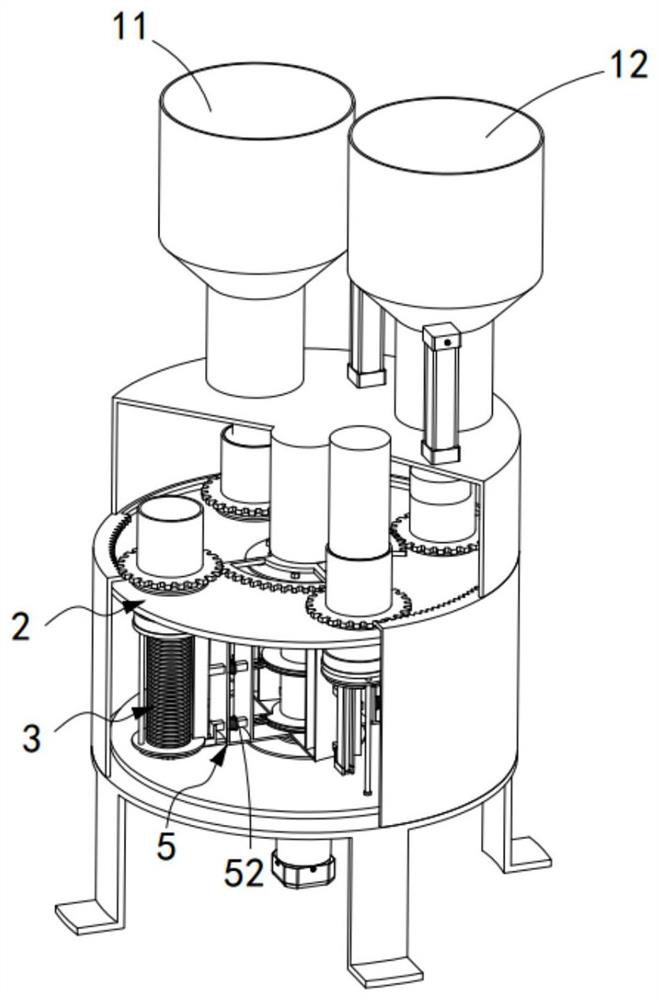

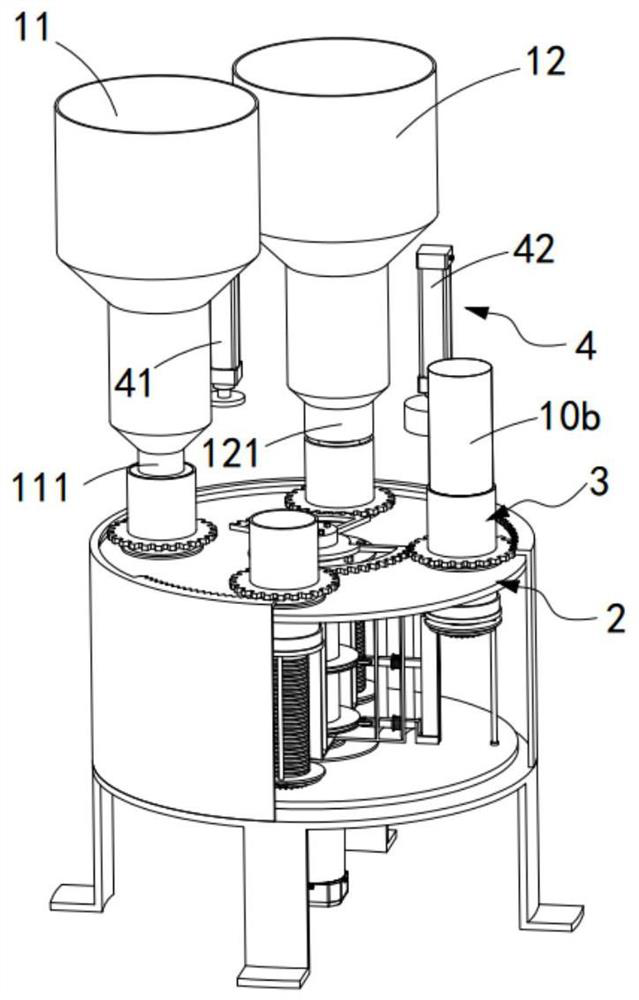

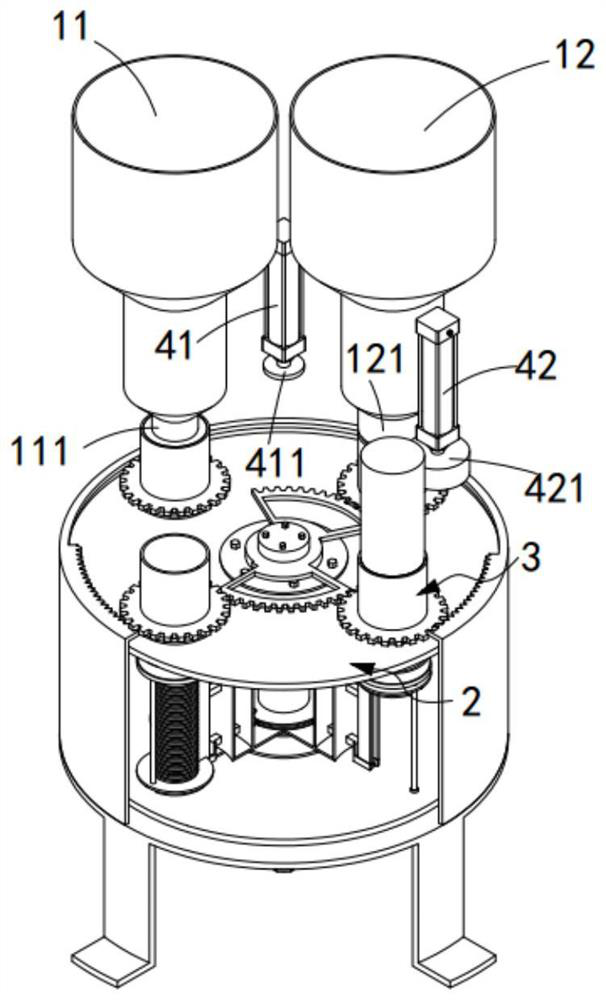

[0060] Such as Figure 1 to Figure 8 As shown, a graphite product production equipment with bright colors on the surface includes a first feeding bin 11 and a second feeding bin 12 arranged side by side, the graphite raw material mixture after stirring and kneading is stored in the first feeding bin 11, and the The graphite raw material mixture containing fluoride salt after stirring and kneading is stored in the second feeding bin 12, and the first feeding bin 11 and the second feeding bin 12 are all provided with inductors for the induction forming device 3, and the inductors sense After the forming device 3, start the first feeding bin 11 and the second feeding bin 12 for feeding;

[0061] The turntable 2, the turntable 2 is rotatably arranged directly below the first feeding bin 11 and the second feeding bin 12, along the rotation direction of the turntable 2, the first feeding bin 11 is located in the second feeding bin the front of bin 12;

[0062] Forming device 3, sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com