A kind of small molecule heavy oil viscosity reducing polymer and preparation method thereof

A technology of small molecules and polymers, applied in drilling compositions, chemical instruments and methods, etc., to achieve the effects of good injection performance, enhanced amphiphilicity, and rapid dissolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

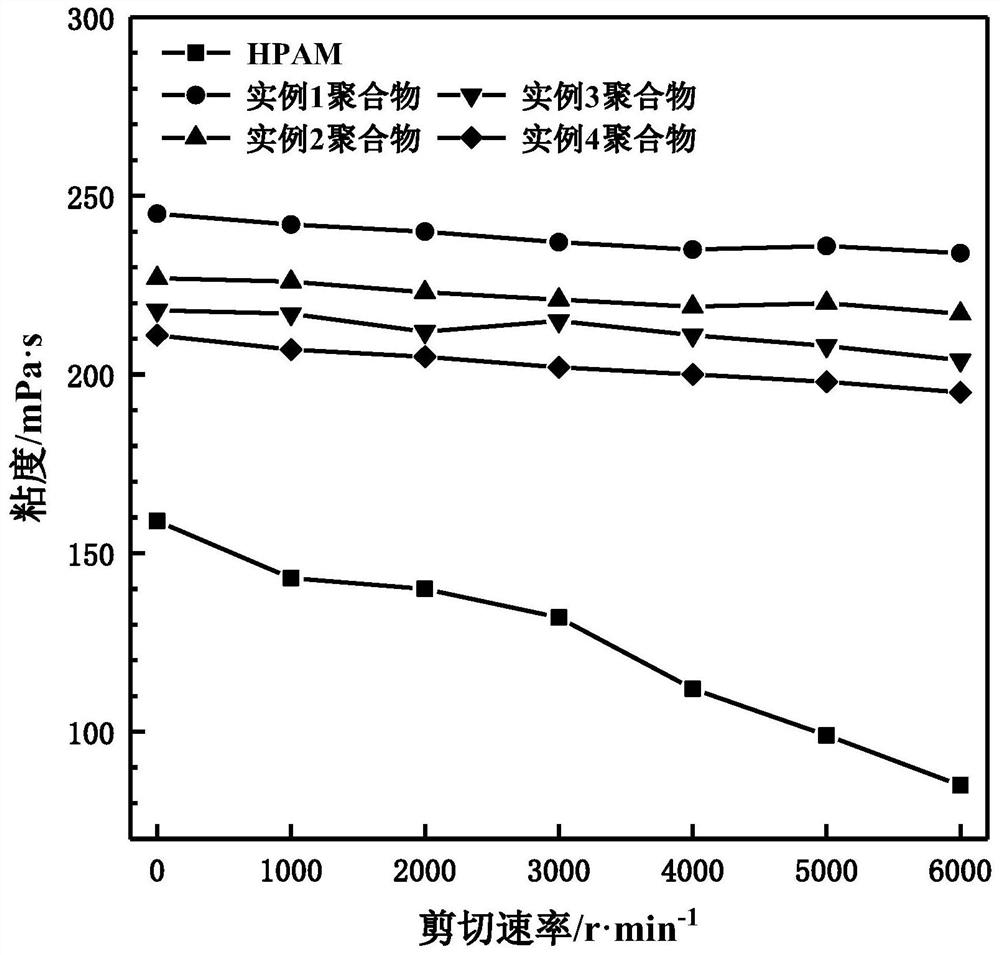

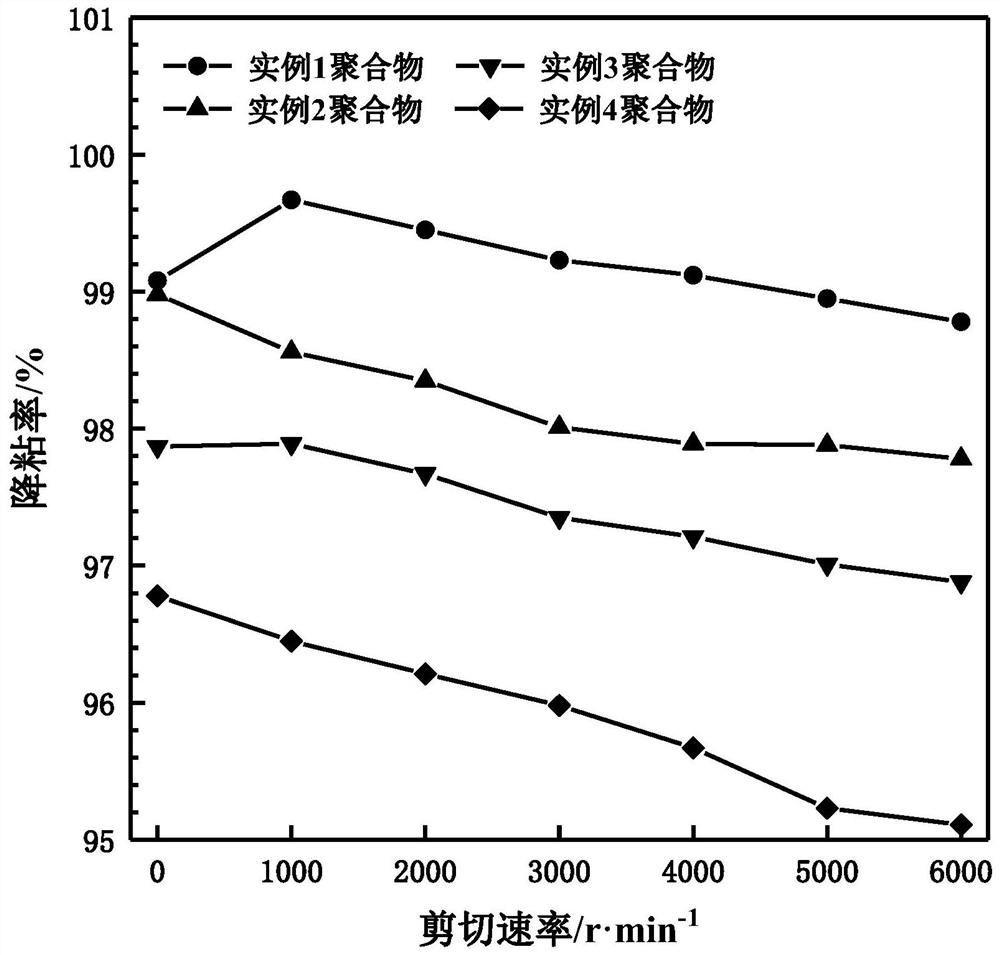

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

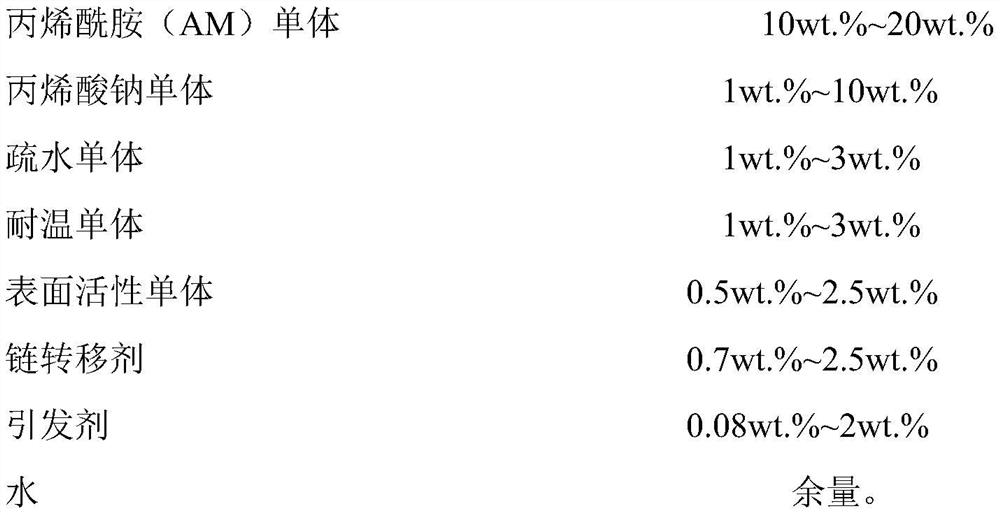

[0044] The present embodiment synthesizes a small-molecule heavy oil viscosity-reducing polymer, and its raw materials, calculated by mass, include:

[0045] Acrylamide monomer 8.672g; sodium acrylate monomer 3.845g; hydrophobic monomer 0.898g; temperature-resistant monomer 0.722g; surface active monomer 0.375g; initiator 0.06g; chain transfer agent 0.788g; distilled water 34.64g.

[0046] The hydrophobic monomer used was cetyldimethylallylammonium chloride.

[0047] The temperature-resistant monomer used was sodium 4-styrene sulfonate.

[0048] The surface-active monomer used was vinyl polyoxyethylene ether.

[0049] The initiator used is a mixed system of potassium persulfate / sodium bisulfite (molar ratio 1:1).

[0050] The chain transfer agent used was a RAFT chain transfer agent of formula I.

[0051] The preparation process includes the following steps:

[0052] (1) Weigh out 8.672g of acrylamide, 3.845g of sodium acrylate, 0.898g of hydrophobic monomer, 0.722g of tempe...

Embodiment 2

[0058] The present embodiment synthesizes a small-molecule heavy oil viscosity-reducing polymer, and its raw materials, calculated by mass, include:

[0059] Acrylamide 6.899g; sodium acrylate 2.344g; hydrophobic monomer 1.021g; temperature-resistant monomer 0.986g; surface active monomer 0.675g; initiator 0.078g; chain transfer agent 0.672g; distilled water 37.325g.

[0060] The hydrophobic monomer used was cetyldimethylallylammonium chloride.

[0061] The temperature-resistant monomer used was sodium 4-styrene sulfonate.

[0062] The surface-active monomer used was vinyl polyoxyethylene ether.

[0063] The initiator used is a mixed system of potassium persulfate / sodium bisulfite (molar ratio 1:1).

[0064] The chain transfer agent used was a RAFT chain transfer agent of formula I.

[0065] The preparation process includes the following steps:

[0066] (1) Weigh out 6.899g of acrylamide, 2.344g of sodium acrylate, 1.021g of hydrophobic monomer, 0.986g of temperature-resis...

Embodiment 3

[0072] The present embodiment synthesizes a small-molecule heavy oil viscosity-reducing polymer, and its raw materials, calculated by mass, include:

[0073] Acrylamide monomer 8.672g; sodium acrylate monomer 3.845g; hydrophobic monomer 0.898g; temperature-resistant monomer 0.722g; surface active monomer 0.375g; initiator 0.06g; chain transfer agent 0.788g; distilled water 34.64g.

[0074] The hydrophobic monomer used was cetyldimethylallylammonium chloride.

[0075] The temperature resistant monomer used was 2-acrylamide-2-methylpropanesulfonic acid (AMPS).

[0076] The surface-active monomer used was vinyl polyoxyethylene ether.

[0077] The initiator used is a mixed system of potassium persulfate / sodium bisulfite (molar ratio 1:1).

[0078] The chain transfer agent used was a RAFT chain transfer agent of formula I.

[0079] The preparation process includes the following steps:

[0080] (1) Weigh out 8.672g of acrylamide, 3.845g of sodium acrylate, 0.898g of hydrophobic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com