Straw textile fiber and production process thereof

A technology of textile fiber and corn stalk fiber, applied in the field of textile fiber, can solve the problems of poor utilization of corn stalk, weak interface interaction force, and inability to form a stable system, etc., achieve excellent mechanical properties, rough surface, and reduce peeling reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

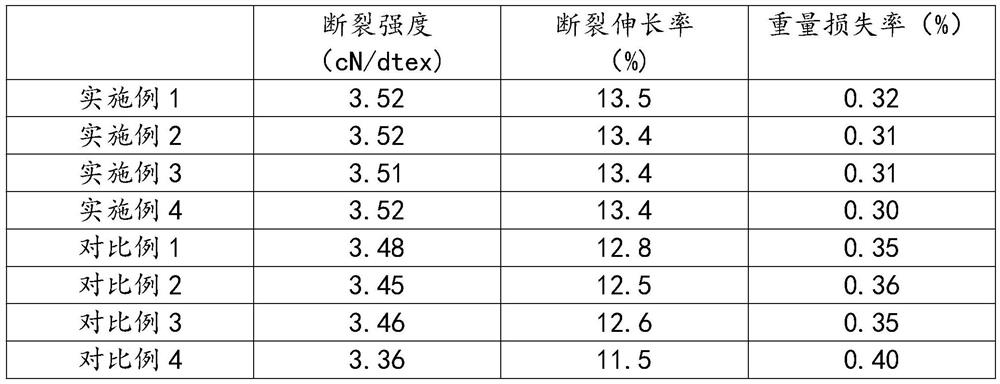

Examples

Embodiment 1

[0029] A straw textile fiber, made of the following raw materials in parts by weight: 10 parts of degummed corn straw fiber, 20 parts of sodium hydroxide, 2 parts of sodium dithionite, and 250 parts of deionized water;

[0030] The straw textile fiber is made by the following method:

[0031] Step S1, mix the degummed corn stalk fiber and sodium hydroxide into deionized water, heat in a water bath at 35°C and stir magnetically for 20 minutes to prepare the preliminarily treated corn stalk fiber, then add sodium dithionite, heat up to 60°C, and heat up to 60°C at 120 Stir at a speed of -150r / min for 10min, react at this temperature for 1h, and prepare modified straw fibers;

[0032] Step S2, soak and refine the modified straw fiber, then mix it with urea according to the weight ratio of 1:5, add it to xylene, raise the temperature to 90°C and react for 1 hour, then transfer it to 3% dilute acetic acid solution to obtain Spinning dope A;

[0033] Step S3, adding polyvinyl alco...

Embodiment 2

[0039] A straw textile fiber, made of the following raw materials in parts by weight: 12 parts of degummed corn stalk fiber, 24 parts of sodium hydroxide, 3 parts of sodium dithionite, and 280 parts of deionized water;

[0040] The straw textile fiber is made by the following method:

[0041] Step S1, mix the degummed corn stalk fiber and sodium hydroxide into deionized water, heat in a water bath at 35°C and stir magnetically for 20 minutes to prepare the preliminarily treated corn stalk fiber, then add sodium dithionite, heat up to 60°C, and heat up to 60°C at 120 Stir at a speed of -150r / min for 10min, react at this temperature for 1h, and prepare modified straw fibers;

[0042] Step S2, soak and refine the modified straw fiber, then mix it with urea according to the weight ratio of 1:5, add it to xylene, raise the temperature to 90°C and react for 1 hour, then transfer it to 3% dilute acetic acid solution to obtain Spinning dope A;

[0043] Step S3, adding polyvinyl alco...

Embodiment 3

[0046] A straw textile fiber, made of the following raw materials in parts by weight: 14 parts of degummed corn stalk fiber, 26 parts of sodium hydroxide, 4 parts of sodium dithionite, and 300 parts of deionized water;

[0047] The straw textile fiber is made by the following method:

[0048] Step S1, mix the degummed corn stalk fiber and sodium hydroxide into deionized water, heat in a water bath at 35°C and stir magnetically for 20 minutes to prepare the preliminarily treated corn stalk fiber, then add sodium dithionite, heat up to 60°C, and heat up to 60°C at 120 Stir at a speed of -150r / min for 10min, react at this temperature for 1h, and prepare modified straw fibers;

[0049] Step S2, soak and refine the modified straw fiber, then mix it with urea according to the weight ratio of 1:5, add it to xylene, raise the temperature to 90°C and react for 1 hour, then transfer it to 3% dilute acetic acid solution to obtain Spinning dope A;

[0050] Step S3, adding polyvinyl alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com