A system and method for mixing and burning sludge in a medium-temperature separation circulating fluidized bed boiler

A circulating fluidized bed and sludge technology, which is applied in the direction of fluidized bed combustion equipment, combustion methods, fuel burned in a molten state, etc., can solve the problems of uneven distribution of sludge, immaturity, and high moisture content, and achieve the goal of conveying Simple and reliable, prevent excessive agglomeration, continuous delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings.

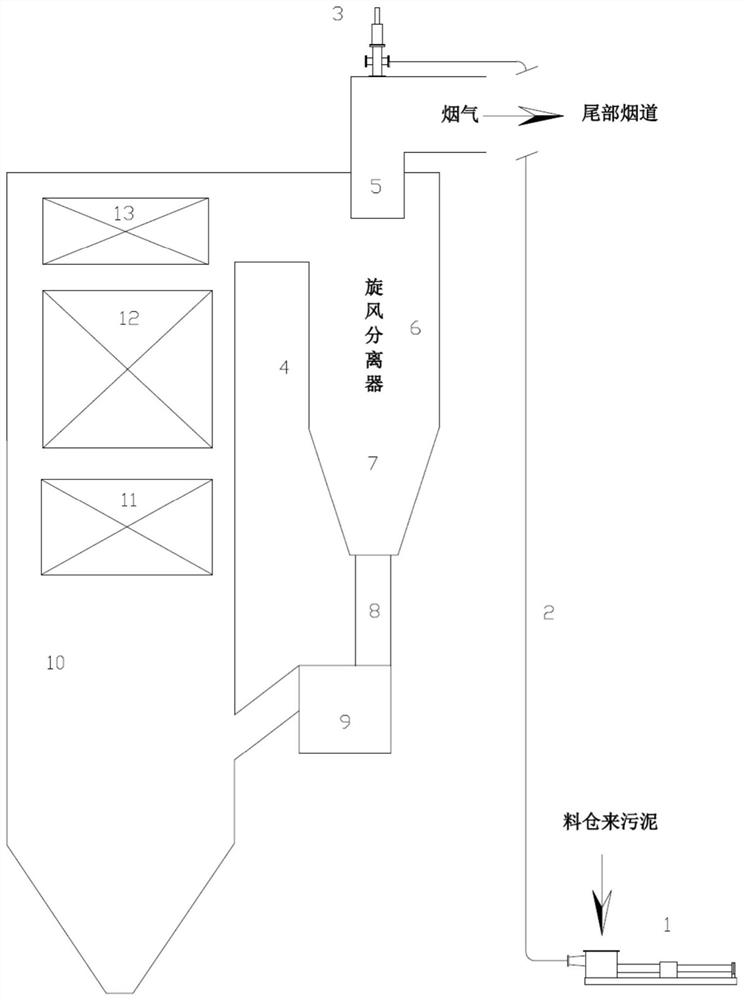

[0032] see figure 1 , The present invention provides a system for mixing and burning sludge in a medium-temperature separation circulating fluidized bed boiler, the system includes a plunger pump 1, a pumping pipeline 2, a vertical feeder 3, a medium-temperature separation cyclone 4, a return Feeding device 9, circulating fluidized bed boiler furnace 10. The medium-temperature separation cyclone 4 consists of a central barrel 5, a separator barrel 6, a separator cone 7 and a separator ash discharge port 8, the circulating fluidized bed boiler is a medium-temperature separation circulating bed boiler, and the circulating fluidized bed boiler furnace 10 An evaporator 11 , a superheater 12 and a high temperature economizer 13 are arranged in the upper part in order from bottom to top. The sludge from the silo is inhaled from the inlet of the plunger pump 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com