Lithium ion battery positive plate using cobalt-free high-nickel positive electrode material

A technology for lithium ion batteries and positive electrode materials, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems that the positive electrode sheet is difficult to meet the long cycle test, the rate cycle performance and the control of element composition are not satisfactory, etc. Good cycle performance, reduced material cost, strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A lithium-ion battery cathode sheet using a cobalt-free high-nickel cathode material, comprising a cathode current collector copper foil and an anode active material layer loaded on the copper foil, the composition of the anode active material layer including a mass ratio of 19:1:1 Cobalt-free high-nickel cathode material, acetylene black and binder.

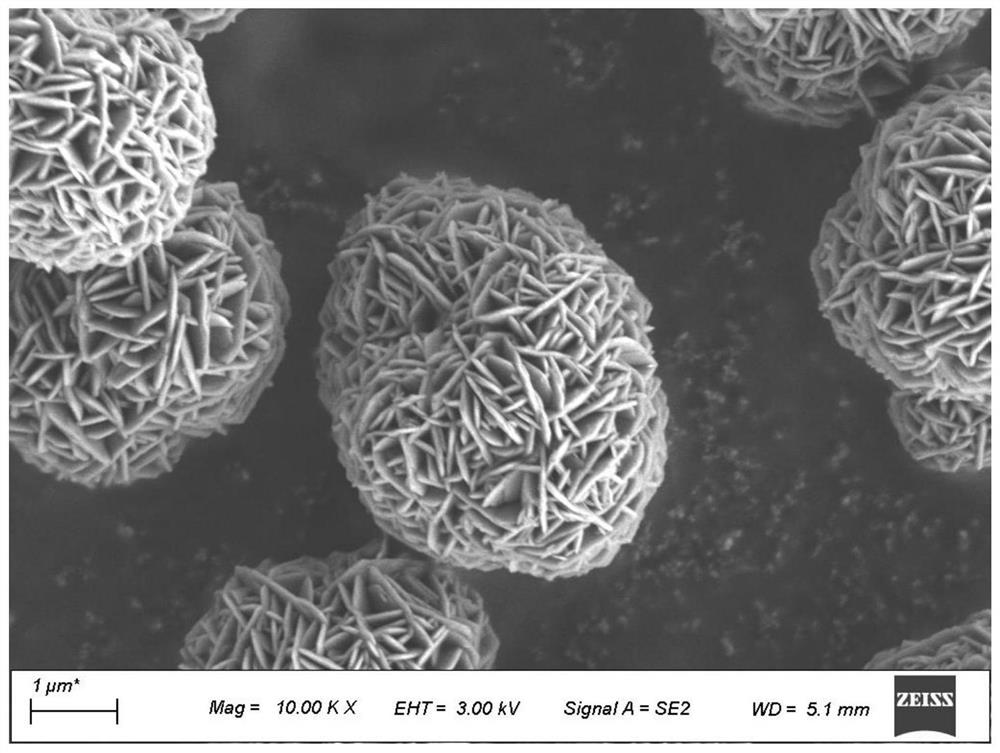

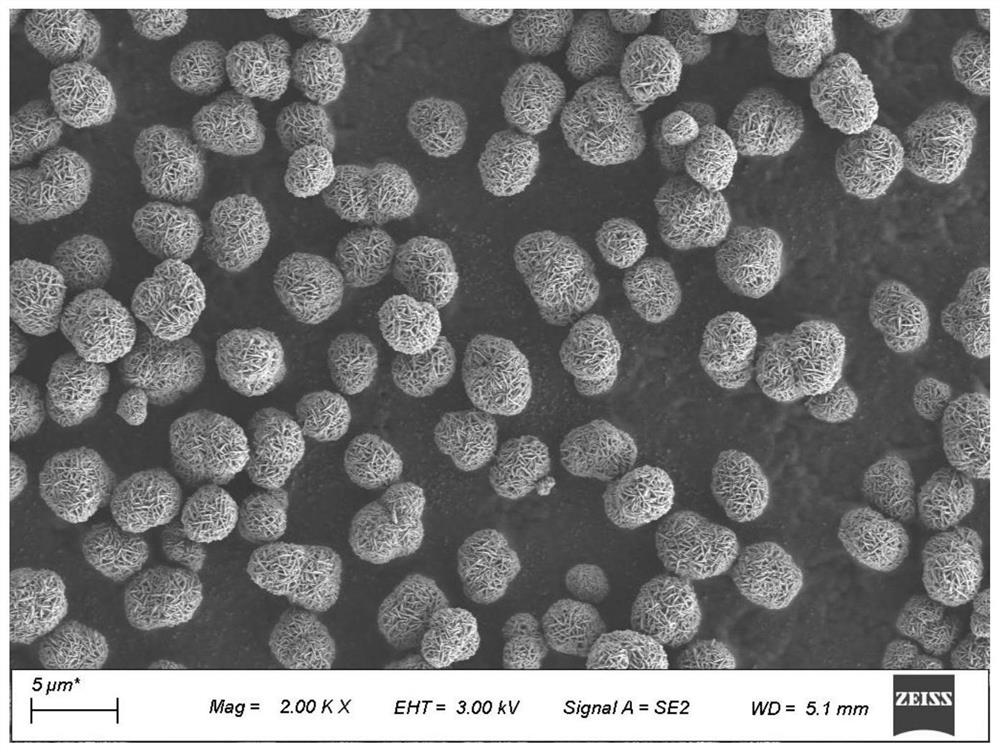

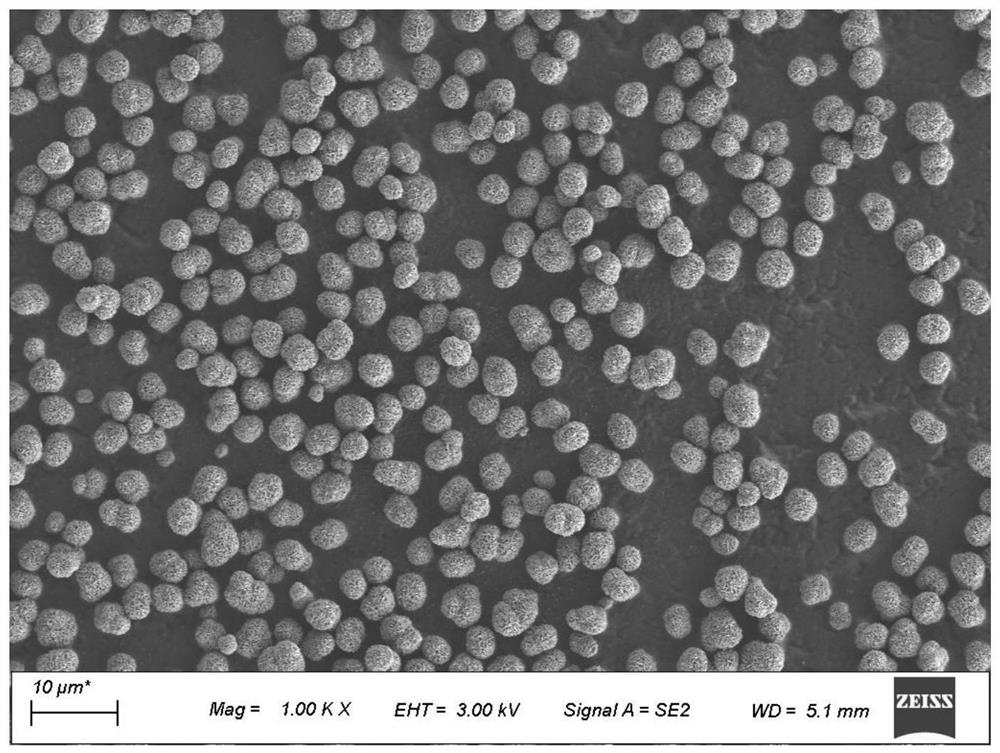

[0040] The molecular formula of the cobalt-free high-nickel cathode material is Li(Ni 0.9 mn 0.1 )Zr 0.0023 o 2 , the preparation method of cobalt-free high-nickel positive electrode material is:

[0041] (1) Mix deionized water with a volume ratio of 5:1 and concentrated ammonia water with a mass concentration of 26% into the coprecipitation reactor, and stir at 60°C at a speed of 600r / min to obtain a reaction bottom liquid;

[0042] (2) NiSO 4 ·6H 2 O, MnSO 4 ·5H 2 O and ZrCl 4 Dissolve in water according to the molar ratio of Ni, Mn, and Zr atoms to form a mixed salt solution, and the total concentration of ea...

Embodiment 2

[0052] A lithium-ion battery cathode sheet using a cobalt-free high-nickel cathode material, comprising a cathode current collector copper foil and an anode active material layer loaded on the copper foil, the composition of the anode active material layer including a mass ratio of 18:1:1 A cobalt-free high-nickel cathode material, a single-walled carbon nanotube and a binder.

[0053] The molecular formula of the cobalt-free high-nickel cathode material is Li(Ni 0.7 mn 0.3 )Zr 0.002 o 2 , the preparation method of cobalt-free high-nickel positive electrode material is:

[0054] (1) Mix deionized water with a volume ratio of 4.5:1 and concentrated ammonia water with a mass concentration of 25% into the co-precipitation reactor, and stir at 40°C at a speed of 900r / min to obtain a reaction bottom liquid;

[0055] (2) NiSO 4 ·6H 2 O, MnSO 4 ·5H 2 O and ZrCl 4 Dissolve in water according to the molar ratio of Ni, Mn, and Zr atoms to form a mixed salt solution, and the tot...

Embodiment 3

[0065] A lithium-ion battery positive electrode sheet using a cobalt-free high-nickel positive electrode material, comprising a positive electrode current collector copper foil and a positive electrode active material layer loaded on the copper foil, the composition of the positive electrode active material layer includes a mass ratio of 20:1:1 A cobalt-free high-nickel cathode material, a single-walled carbon nanotube and a binder.

[0066] The molecular formula of the cobalt-free high-nickel cathode material is Li(Ni 0.5 mn 0.5 )Zr 0.003 o 2 , the preparation method of cobalt-free high-nickel positive electrode material is:

[0067] (1) Mix deionized water with a volume ratio of 5.5:1 and concentrated ammonia water with a mass concentration of 28% into the co-precipitation reactor, and stir at 80°C at a speed of 500r / min to obtain a reaction bottom liquid;

[0068] (2) NiSO 4 ·6H 2 O, MnSO 4 ·5H 2 O and ZrCl 4 Dissolve in water according to the molar ratio of Ni, Mn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com