Treatment method of organophosphorus-containing wastewater

A treatment method, organic phosphorus technology, applied in the direction of water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of weak ozone oxidation ability and little effect of organic phosphorus, and achieve Efficient control, easy operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

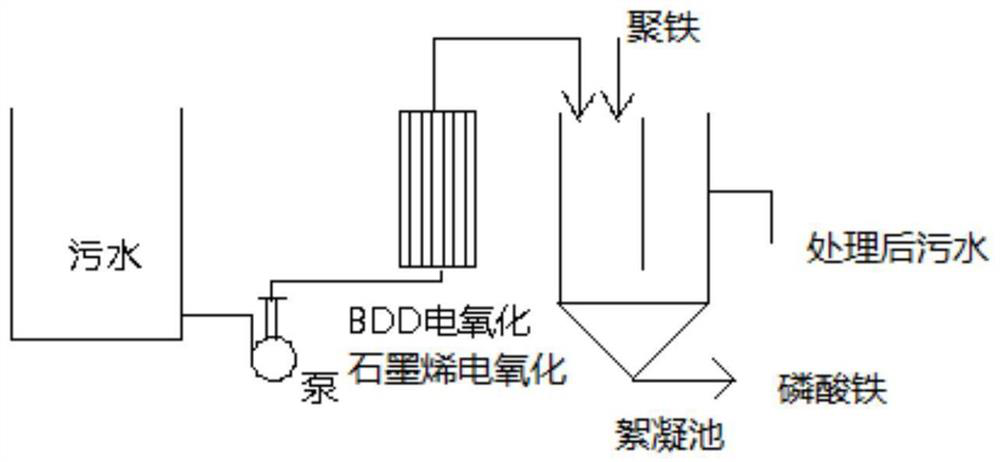

[0020] Embodiment 1. The organophosphorus wastewater of 100mg / l is processed, and the process is as follows:

[0021] Step 1. Use BDD electrodes and graphene electrodes to pretreat wastewater. The current density of graphene electrodes is 300A / square meter, the current density of BDD electrodes is 500A / square meter, and the number of BDD electrodes is 5%. During the pretreatment process Reduce the COD in the sewage, decompose the refractory organic matter into small molecule organic matter, and convert organic phosphorus into inorganic phosphorus at the same time, and carry out pretreatment to facilitate subsequent flocculation treatment;

[0022] Step 2: Adding polyferron as a flocculant into a flocculation tank to flocculate the pretreated wastewater to obtain iron phosphate and phosphorous-containing discharge wastewater up to standard, wherein the molar amount of polyferric is not less than that of organic phosphorus.

Embodiment 2

[0023] Embodiment 2. The organophosphorus wastewater of 100mg / l is processed, and the process is as follows:

[0024] Step 1. Use BDD electrodes and graphene electrodes to pretreat wastewater. The current density of graphene electrodes is 600A / square meter, the current density of BDD electrodes is 800A / square meter, and the number of BDD electrodes is 7%. During the pretreatment process Reduce the COD in the sewage, decompose the refractory organic matter into small molecule organic matter, and convert organic phosphorus into inorganic phosphorus at the same time, and carry out pretreatment to facilitate subsequent flocculation treatment;

[0025] Step 2: Adding polyferron as a flocculant into a flocculation tank to flocculate the pretreated wastewater to obtain iron phosphate and phosphorous-containing discharge wastewater up to standard, wherein the molar amount of polyferric is not less than that of organic phosphorus.

Embodiment 3

[0026] Embodiment 3. The organophosphorus wastewater of 100mg / l is processed, and the process is as follows:

[0027] Step 1. Use BDD electrodes and graphene electrodes to pretreat wastewater. The current density of graphene electrodes is 1000A / square meter, the current density of BDD electrodes is 1000A / square meter, and the number of BDD electrodes is 10%. During the pretreatment process Reduce the COD in the sewage, decompose the refractory organic matter into small molecule organic matter, and convert organic phosphorus into inorganic phosphorus at the same time, and carry out pretreatment to facilitate subsequent flocculation treatment;

[0028] Step 2: Adding polyferron as a flocculant into a flocculation tank to flocculate the pretreated wastewater to obtain iron phosphate and phosphorous-containing discharge wastewater up to standard, wherein the molar amount of polyferric is not less than that of organic phosphorus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com