A kind of high-yield spironolactone fine preparation method

A spironolactone and high-yield technology, which is applied in the field of high-yield spironolactone high-quality preparation, can solve the problems of low refining yield and spironolactone yield, and achieve the effect of improving the refining yield and reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

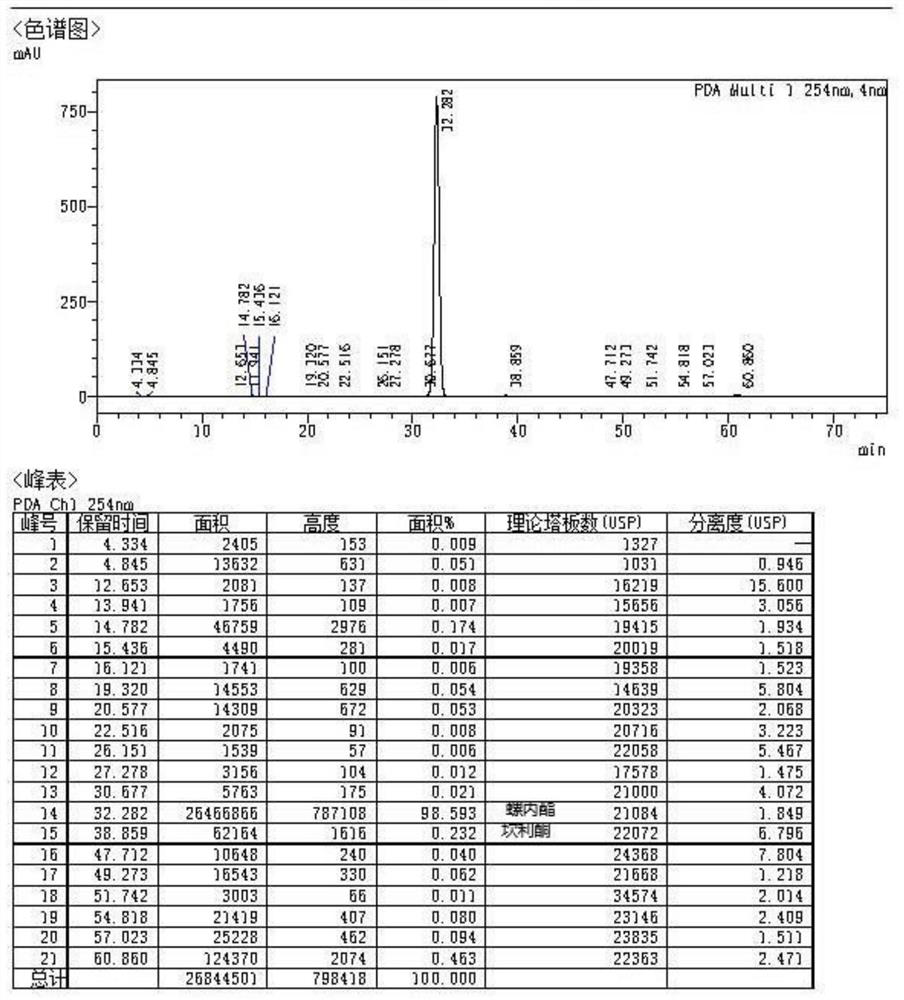

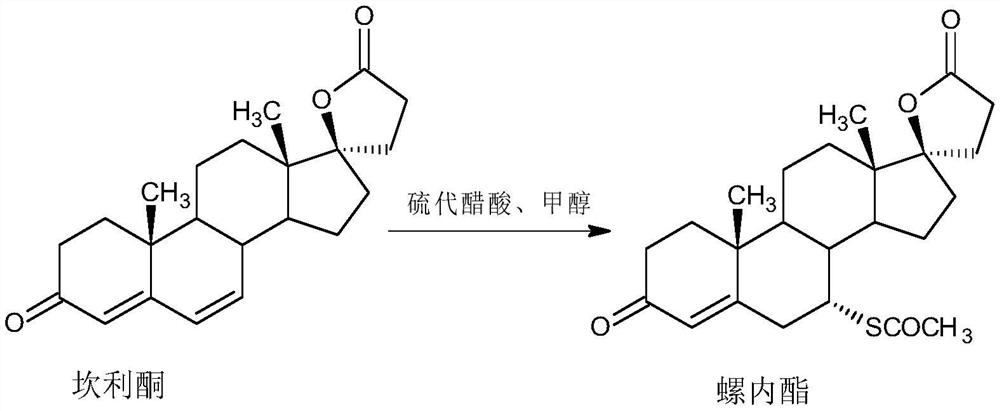

[0026] Put 10g of canrenone into 10ml of thioacetic acid, add 100ml of methanol, reflux for 3 hours, cool down to 0°C, filter to get the crude spironolactone, put the crude spironolactone into 50ml of ethanol, add 0.01g of pyridine, and then add 0.2g of activated carbon , after the decolorization finishes, filter out gac, concentrate, filter, dry to obtain 9.9g spironolactone fine work, yield 99%, HPLC sees attached figure 1 , from attached figure 1 It can be seen that the purity of the obtained spironolactone refined product is 98.593%, and the impurity canrenone content is 0.232%.

Embodiment 2

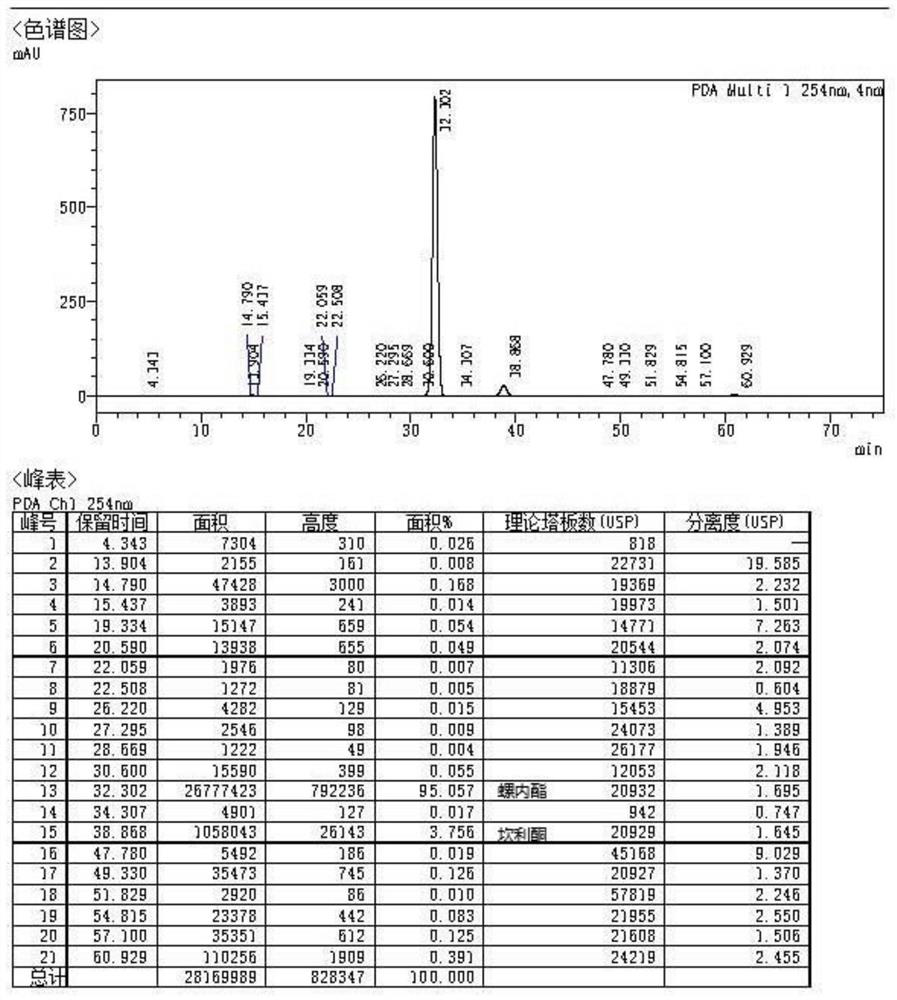

[0028] Put 10g of canrenone into 5ml of thioacetic acid, add 50ml of methanol, reflux for 2 hours, cool down to 0°C, filter to get the crude spironolactone, put the crude spironolactone into 300ml of methanol, add 0.05g of triethylamine, and then add 0.5 g activated carbon, after the decolorization finishes, filter the activated carbon, concentrate, filter, and dry to obtain 9.9g spironolactone fine product, the yield is 99%, and the purity is 99.5%.

Embodiment 3

[0030] Put 10g of canrenone into 8ml of thioacetic acid, add 80ml of methanol, reflux for 5 hours, cool down to 0°C, filter to obtain the crude spironolactone, put the crude spironolactone into 15ml of dichloromethane and 15ml of acetone, add 0.1g1,8 -diazabicycloundec-7-ene (DBU), then add 1g of gac, filter gac after decolorization, concentrate, filter, dry to obtain 9.8g spironolactone fine product, yield 98%, purity 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com