Hybrid magnetic circuit permanent magnet synchronous motor for electric automobile and driving method thereof

A permanent magnet synchronous motor and hybrid magnetic circuit technology, applied in electric vehicles, motor generator control, magnetic circuit rotating parts, etc., can solve problems such as large harmonics, large leakage flux, and prominent cogging torque problems. , to achieve the effect of good structure compactness, good heat dissipation, and high effective magnetic density of the air gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

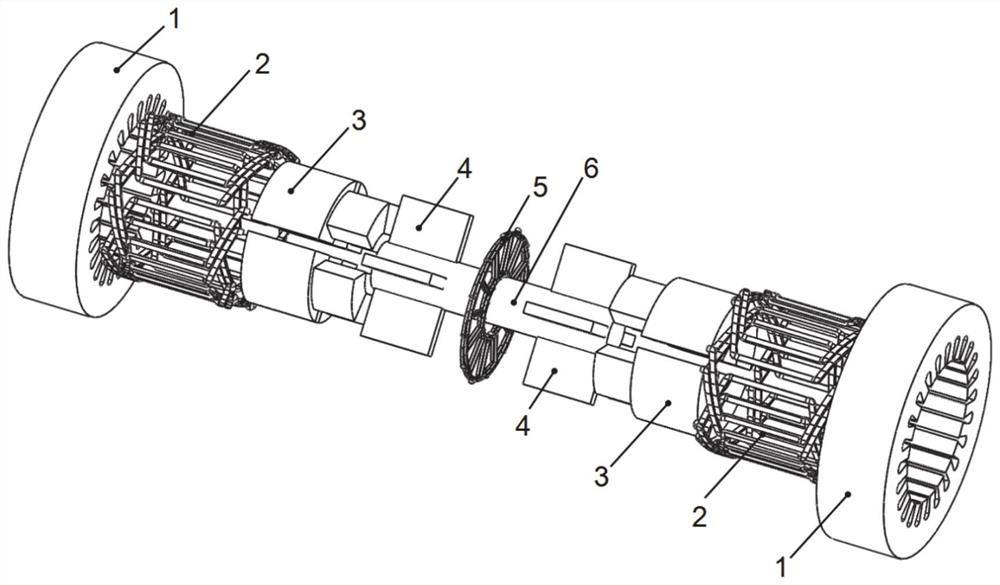

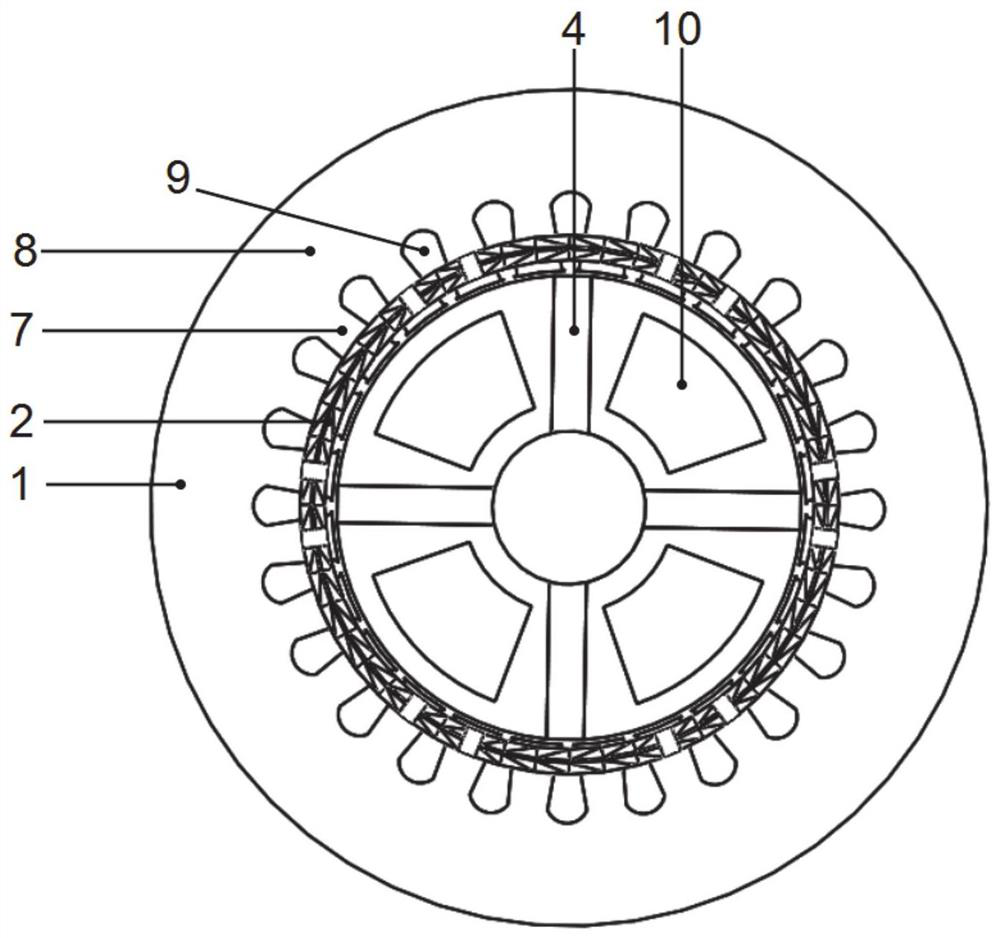

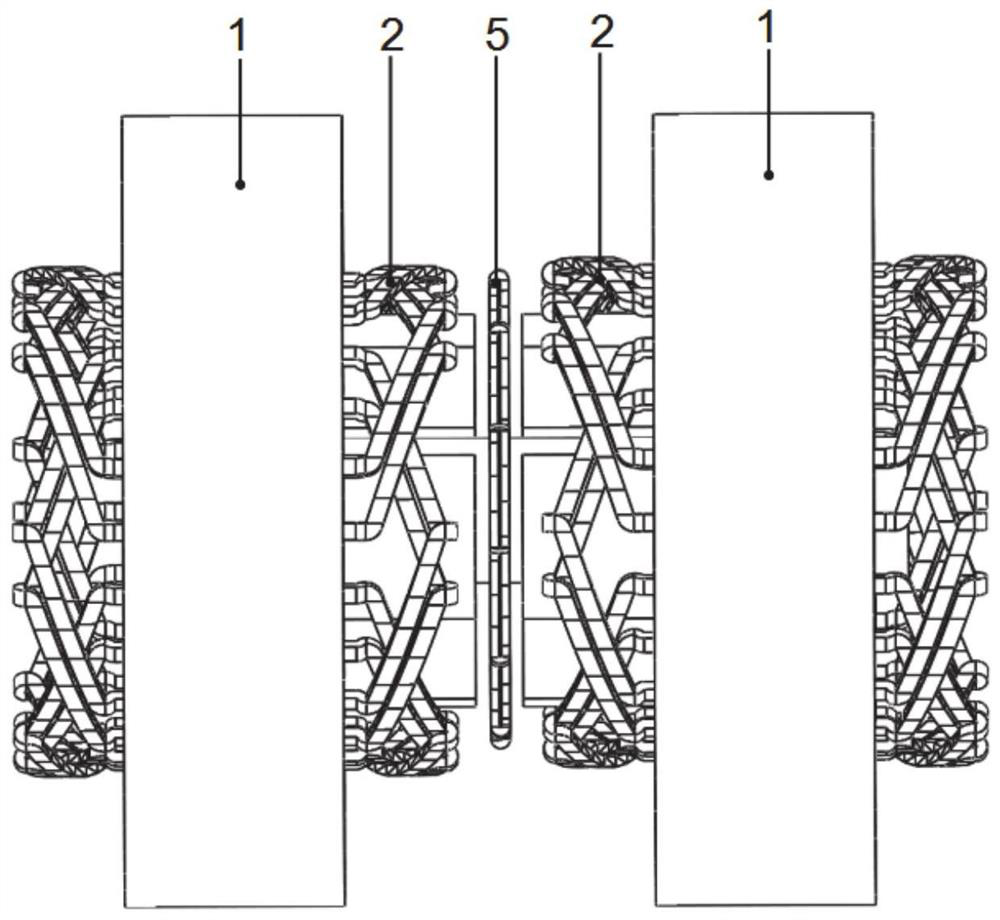

[0068] like figure 1 As shown, the overall three-dimensional schematic diagram of the motor, the number of phases of the motor in this embodiment is 3, the number of radial stator teeth is 24, the number of rotor slots is 8, the number of permanent magnet blocks is 8, the number of radial magnetic poles is 4, and the number of axial magnetic poles is 4. This embodiment includes a radial stator, an axial winding and a rotor. The radial stator is made of laminated silicon steel sheets, such as figure 2 As shown, the radial stator includes radial stator teeth 7, radial stator yoke 8 and radial stator slots 9, radial armature windings 2 are placed in the radial stator slots 9, and the radial armature windings 2 can be distributed windings , concentrated winding or stacked winding, the number of poles of the radial armature winding is consistent with the number of radial magnetic poles of the rotor, the radial stator and the rotor are coaxial, and there is a radial air gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com