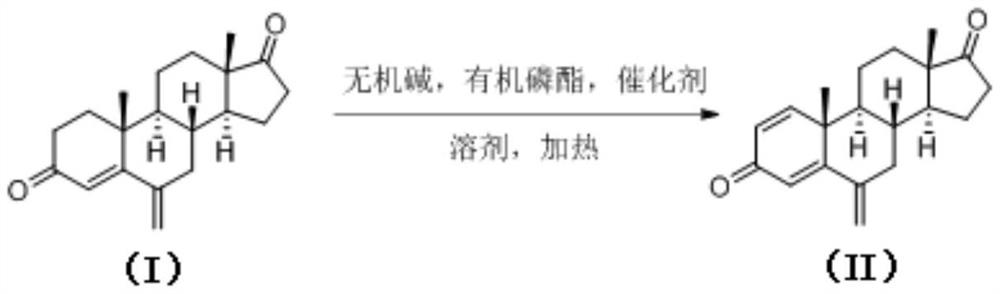

Synthetic method of exemestane

A synthetic method, the technology of exemestane, applied in the field of pharmaceutical chemical synthesis, can solve the problems of difficult purification of oxidation products, large amount of oxidizing agent, expensive starting materials, etc., and achieve the effect of easy purification, high yield and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Allyl diethyl phosphate (52.4g, 0.27mol) was dissolved in anhydrous N,N-dimethylformamide (DMF, 200mL), and then 10% palladium carbon (2.5g) was added. Stirred and reacted for 0.5h, then added anhydrous sodium carbonate (38.2g, 0.36mol) and 6-methyleneandrost-4-ene-3,17-dione (26.9g, 90mmol), heated to reflux for 16h . After cooling to room temperature, the solid insoluble matter was removed by suction filtration, and most of the DMF was evaporated from the filtrate under reduced pressure at 80°C, then water (100 mL) was added, and extracted with dichloromethane (70 mL×3). After the organic phases were combined, they were washed with saturated sodium chloride solution (100mL×2), and the layers were separated. The organic phase was evaporated under reduced pressure at 30°C to remove the solvent, and the residue was dissolved in methanol (80mL), decolorized with activated carbon (1g), and filtered. Crystallize at room temperature, recrystallize with ethanol (50mL), and d...

Embodiment 2

[0045] Allyl diethyl phosphate (52.4g, 0.27mol) was dissolved in anhydrous N,N-dimethylformamide (DMF, 300mL), and then 10% palladium carbon (1.9g) was added. Stirred and reacted for 0.5h, then added anhydrous potassium carbonate (49.8g, 0.36mol) and 6-methyleneandrost-4-ene-3,17-dione (26.9g, 90mmol), heated to reflux for 24h . After cooling to room temperature, the solid insoluble matter was removed by suction filtration, and most of the DMF was evaporated from the filtrate under reduced pressure at 80°C, then water (100 mL) was added, and extracted with dichloromethane (70 mL×3). After the organic phases were combined, they were washed with saturated sodium chloride solution (100mL×2), and the layers were separated. The organic phase was evaporated under reduced pressure at 30°C to remove the solvent, and the residue was dissolved in methanol (80mL), decolorized with activated carbon (1g), and filtered. Crystallize at room temperature, recrystallize with ethanol (50 mL), a...

Embodiment 3

[0047] Allyl diethyl phosphate (52.4g, 0.27mol) was dissolved in anhydrous N,N-dimethylformamide (DMF, 200mL), and then 10% palladium carbon (2.5g) was added. Stirred and reacted for 0.5h, then added anhydrous potassium carbonate (74.7g, 0.54mol) and 6-methyleneandrost-4-ene-3,17-dione (26.9g, 90mmol), heated to reflux for 24h . After cooling to room temperature, the solid insoluble matter was removed by suction filtration, and most of the DMF was evaporated from the filtrate under reduced pressure at 80°C, then water (100 mL) was added, and extracted with dichloromethane (70 mL×3). After the organic phases were combined, they were washed with saturated sodium chloride solution (100mL×2), and the layers were separated. The organic phase was evaporated under reduced pressure at 30°C to remove the solvent, and the residue was dissolved in methanol (80mL), decolorized with activated carbon (1g), and filtered. Crystallize at room temperature, recrystallize with ethanol (50 mL), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com