Preparation method of water-soluble tantalum solution

A water-soluble, water-soluble technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of affecting coating quality, increasing production cost, exceeding the standard, etc., to achieve the effect of reducing production cost, enhancing long life and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

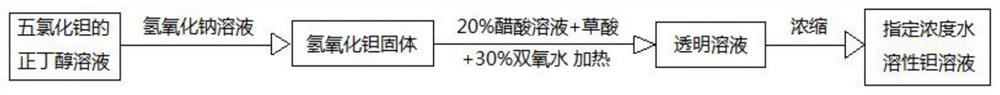

[0025] A kind of preparation method of water-soluble tantalum solution, flow process is as follows figure 1 As shown, follow the steps below:

[0026] Using tantalum pentachloride n-butanol solution with a tantalum content of 200g / L as the starting material, the tantalum pentachloride is hydrolyzed to generate tantalum hydroxide solid by adding aqueous sodium hydroxide solution, and the tantalum hydroxide solid is added to the volume concentration of 20% In the acetic acid solution, add oxalic acid and heat, add dropwise 30% hydrogen peroxide solution until the solution is transparent, and concentrate to the specified concentration.

[0027] Wherein, the pH value of aqueous sodium hydroxide solution is 12-14, and the volume ratio of aqueous sodium hydroxide solution and tantalum pentachloride n-butanol solution is (2-1): 1, and reaction temperature is room temperature, and the time is 15-30 minutes; Tantalum hydroxide (g): 20% acetic acid solution (mL): oxalic acid (g) = 1: (...

Embodiment 1

[0032]In an ordinary workshop, the n-butanol solution of tantalum pentachloride with a tantalum content of 200g / L is used as the starting material, and the tantalum pentachloride is hydrolyzed to generate tantalum hydroxide solid by adding an aqueous solution of sodium hydroxide with a pH value of 12. The volume ratio of sodium hydroxide aqueous solution to tantalum pentachloride n-butanol solution is 1:1, the reaction temperature is room temperature, and the time is 15 minutes; then the tantalum solid is added to the acetic acid solution with a volume concentration of 20%, and then oxalic acid is added After heating, add 30% hydrogen peroxide solution dropwise until the solution is transparent, wherein tantalum hydroxide (g): 20% acetic acid solution (mL): oxalic acid (g) = 1:20:4; oxalic acid (g): 30% hydrogen peroxide (mL )=1:10, the reaction temperature is 100°C, the time is 1 hour, concentrated to obtain a water-soluble tantalum solution with a tantalum content of 10%, and...

Embodiment 2

[0034] In an ordinary workshop, the n-butanol solution of tantalum pentachloride with a tantalum content of 200g / L is used as the starting material, and the tantalum pentachloride is hydrolyzed to generate tantalum hydroxide solid by adding an aqueous solution of sodium hydroxide with a pH value of 14. The volume ratio of sodium hydroxide aqueous solution to tantalum pentachloride n-butanol solution is 2:1, the reaction temperature is room temperature, and the time is 30 minutes; then the tantalum solid is added to the acetic acid solution with a volume concentration of 20%, and then oxalic acid is added After heating, add 30% hydrogen peroxide solution dropwise until the solution is transparent, wherein tantalum hydroxide (g): 20% acetic acid solution (mL): oxalic acid (g) = 1:25:8; oxalic acid (g): 30% hydrogen peroxide (mL )=1:30, the reaction temperature is 110°C, and the time is 1.5 hours. After concentration, a water-soluble tantalum solution with a tantalum content of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com