Method for preparing 2,6-dimethyl-2-heptanol

A technology of dimethyl and heptanol, applied in 2 fields, can solve problems such as difficult to guarantee product yield and operation safety, unobvious triggering, long triggering time, etc., and achieve high product yield, fast triggering speed and easy storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

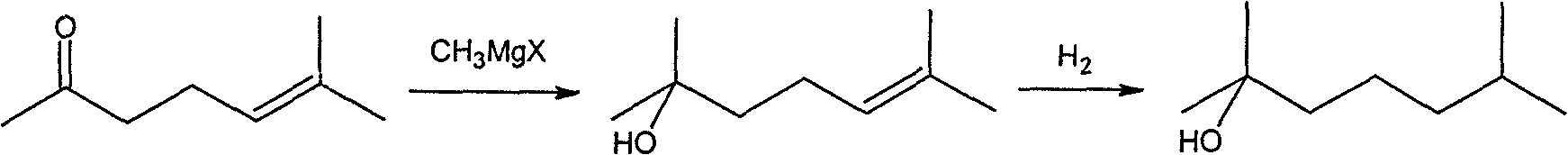

Image

Examples

Embodiment 1

[0025] Preparation of benzylmagnesium chloride: prepare 12.7g (0.1mol) of benzyl chloride and 60mL of tetrahydrofuran, stir for 5min and set aside. Add 2.4g (0.1mol) of freshly treated magnesium powder, 15mL tetrahydrofuran, and 15mL toluene into a clean and dry 250mL four-necked bottle. After stirring for 5 minutes, slowly raise the temperature to 60°C. After stabilization, slowly add 5% of the prepared Benzyl chloride, tetrahydrofuran mixture, the reaction exotherm is obvious, when the temperature no longer rises, it indicates that the reaction has been initiated. Continue to drop the remaining benzyl chloride and tetrahydrofuran mixture, the reaction is obviously exothermic, keep cooling during the process, the reaction temperature is controlled at 10-60°C, the drop is completed in about 6-8 hours, and the reaction is completed after continuing the reaction for 3 hours. Store the prepared initiator in a sealed reagent bottle for later use.

Embodiment 2

[0027] Preparation of benzyl magnesium bromide: prepare 17.1 g (0.1 mol) of benzyl bromide and 100 mL of tetrahydrofuran, stir for 5 min and set aside. Add 2.4g (0.1mol) of freshly treated magnesium powder, 30mL tetrahydrofuran, and 10mL toluene into a clean and dry 250mL four-neck bottle, stir for 5 minutes, then slowly raise the temperature to 60°C, and slowly add 5% of the prepared solution after stabilization The mixture of benzyl bromide and tetrahydrofuran, the reaction exotherm is obvious, and the reaction has been initiated when the temperature no longer rises. Continue to drop the remaining mixture of benzyl bromide and tetrahydrofuran, the reaction is obviously exothermic, keep cooling during the process, the reaction temperature is controlled at 10-60°C, the drop is completed after about 6-10 hours, and the reaction is completed after continuing the reaction for 3 hours. Store the prepared initiator in a sealed reagent bottle for later use.

Embodiment 3

[0029] Preparation of 2,6-dimethyl-5-hepten-2-ol: Add 24g (1mol) of freshly treated magnesium powder and 240mL tetrahydrofuran into a clean, dry 1000mL four-necked flask, and stir at room temperature for 5min. Then add 10g of prepared benzylmagnesium bromide and 4g of benzyl bromide, and the reaction will start rapidly under stirring. After the initiation is complete, slowly feed in methyl chloride and react in a boiling state. The magnesium powder will disappear completely in about 3 to 6 hours. Continue Reaction 1h. Place the prepared four-neck flask of methylmagnesium chloride Grignard reagent in the cooling system, start stirring, and slowly add 126g (1mol) of 6-methyl-5-heptene-2- For ketone, the dropwise addition time is about 2 to 5 hours. After the dropwise addition, continue to react at room temperature for 1 hour. After the reaction, add 200mL of toluene, and recover tetrahydrofuran under normal pressure. After the recovery, slowly add 250g of 20% acetic acid solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com