Online monitoring system and method for oxygen impurities and application

A monitoring system and impurity technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to automatically process data results, limited types of oxide detection, inability to achieve online real-time monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

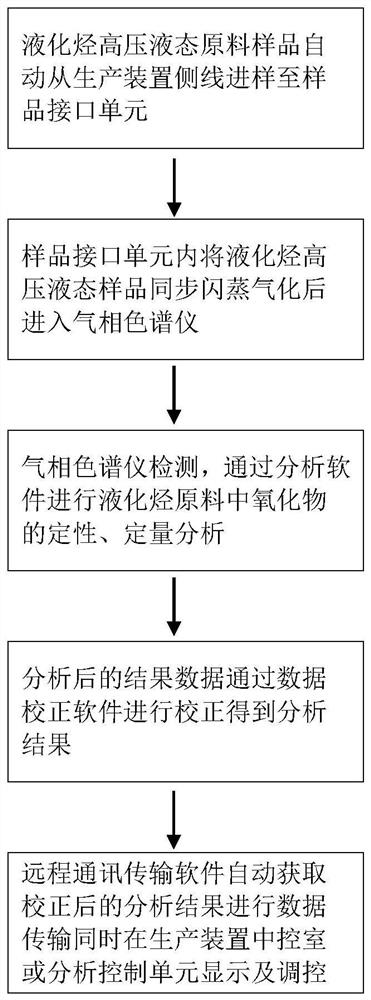

Method used

Image

Examples

Embodiment 1

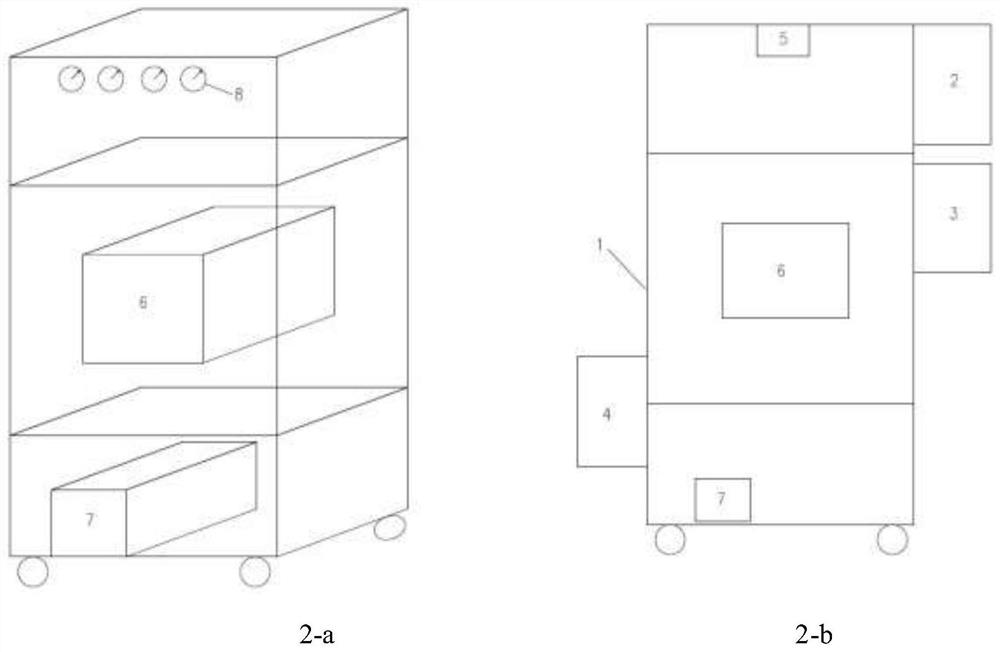

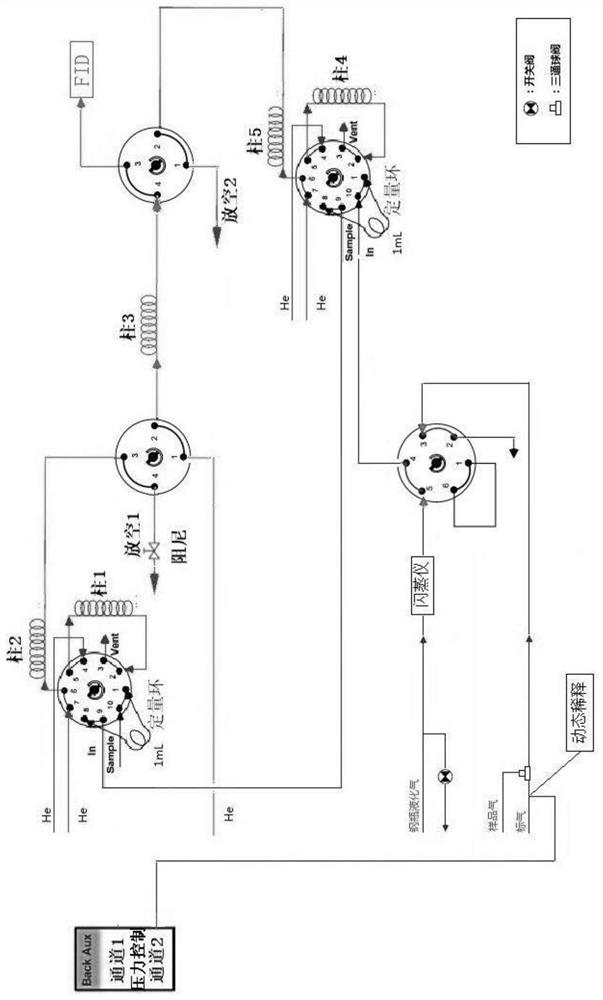

[0075] (1) Establish as Figure 2-3 The online monitoring system for oxygen impurities in liquefied hydrocarbon raw materials is shown. The online monitoring system specifically includes: a movable main box 1, a sample interface unit 2, a standard gas / carrier gas interface unit 3, an electrical appliance / communication interface unit 4, an explosion-proof Processing unit 5, gas chromatograph 6, computer data processing system 7, temperature and pressure display table 8 and vent valve box 9, such as figure 2 Shown is the structural arrangement diagram of the online detection system in the embodiment. The sample inlet of the gas chromatograph 6 is connected to the outlet of the sample processing system for detecting the gasification raw material of liquefied hydrocarbons from the sample interface unit 2 . One end of the computer data processing system 7 is connected to the gas chromatograph 6 , and the other end is connected to the analysis unit through the communication interf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com