Electrode for electrochemical filtration water treatment as well as preparation method and application thereof

An electrochemical and water treatment technology, applied in chemical instruments and methods, water / sewage treatment, water / sludge / sewage treatment, etc. , improve the catalytic efficiency, the effect of high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 20mg Ti 3 C 2 MXene was dissolved in 4 mL of ethanol, and the mixture was sonicated for 30 min; then, 2 mL of 0.2 mol / L Fe 2 SO 4 solution, and 6mg of molybdenum powder, then add 10mL of ethanol, and magnetically stir the solution for 2 hours; then, pour the above reaction solution into a 100mL stainless steel autoclave lined with polytetrafluoroethylene, heat at 120°C for 8 hours, and wait for cooling After being brought to room temperature and centrifuged, the finally obtained precipitate was washed 3 times with ethanol and dried under vacuum at 60°C. The obtained modified MXene was mixed into deionized water and ultrasonicated for 30 minutes, filtered onto a PVDF membrane with a pore size of 0.45 μm by vacuum suction, and dried in vacuum to obtain the required membrane electrode.

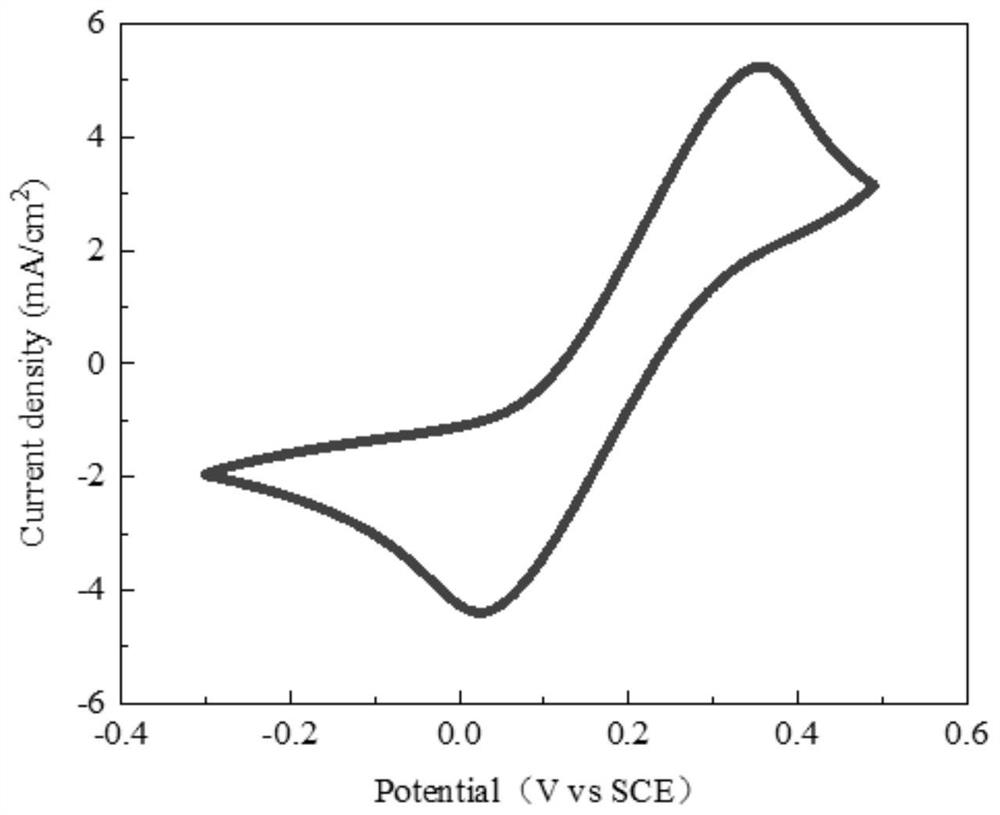

[0025] figure 1 It is the graph of the electrochemical cyclic voltammetry test results of the prepared modified MXene electrode material.

Embodiment 2

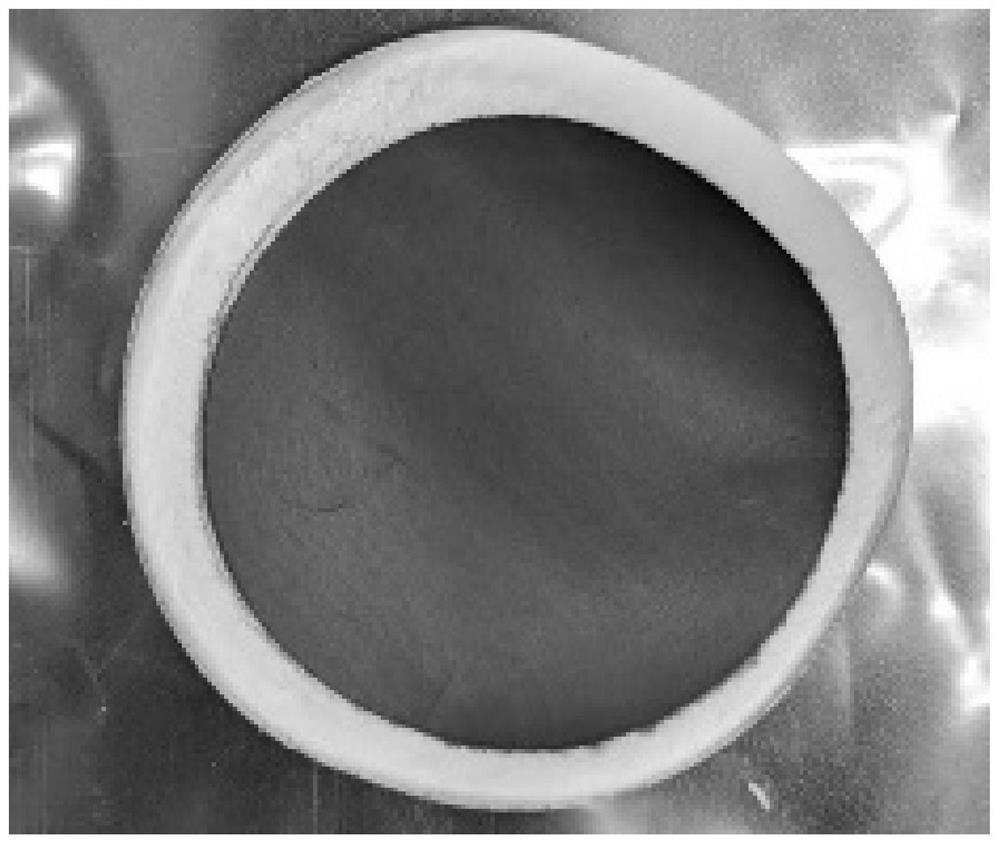

[0027] Take the modified MXene material described in the above-mentioned Example 1, further mix it with carbon nanotubes at a mass ratio of 1:3 and add it to ethanol for 30 minutes, and vacuum filter to a PVDF membrane with a pore size of 0.45 μm After vacuum drying, the desired membrane electrode was obtained. The photo of the prepared electrode is shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com