A kind of aluminum alloy conductor material with high conductivity, heat resistance and creep resistance, preparation method and application thereof

An aluminum alloy conductor and anti-creep technology, applied in the field of metallurgical materials, can solve the problems of increased production cost, complicated preparation process, and no heat resistance of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

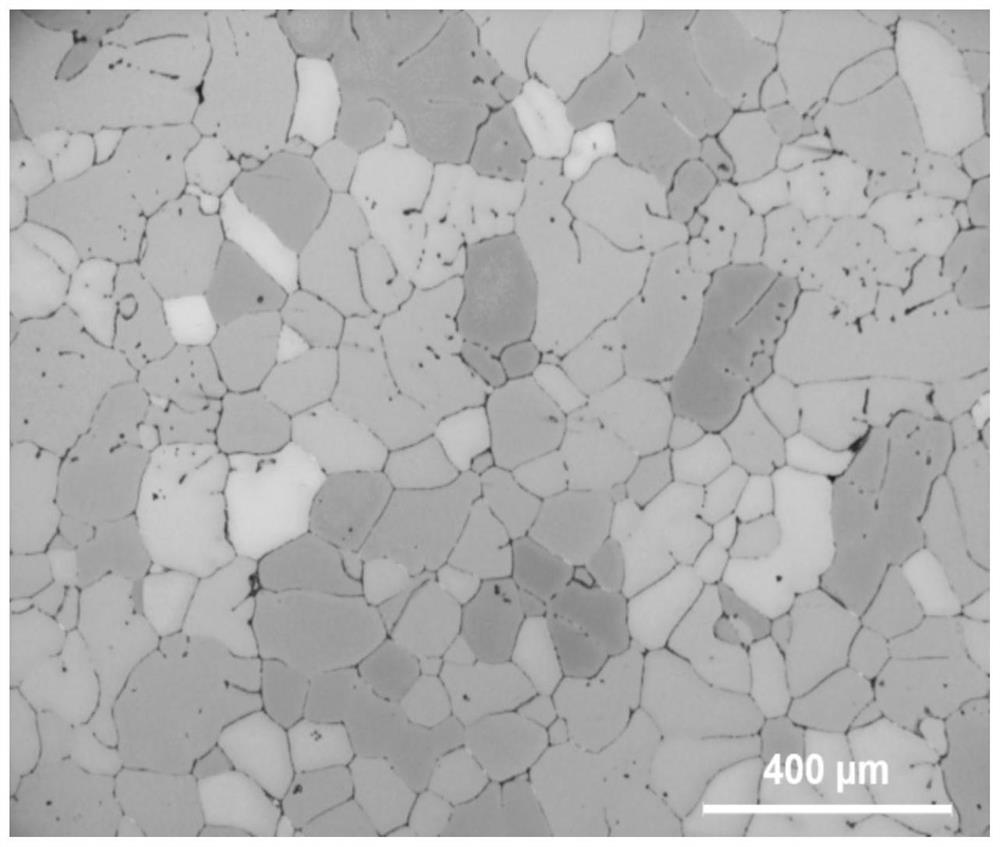

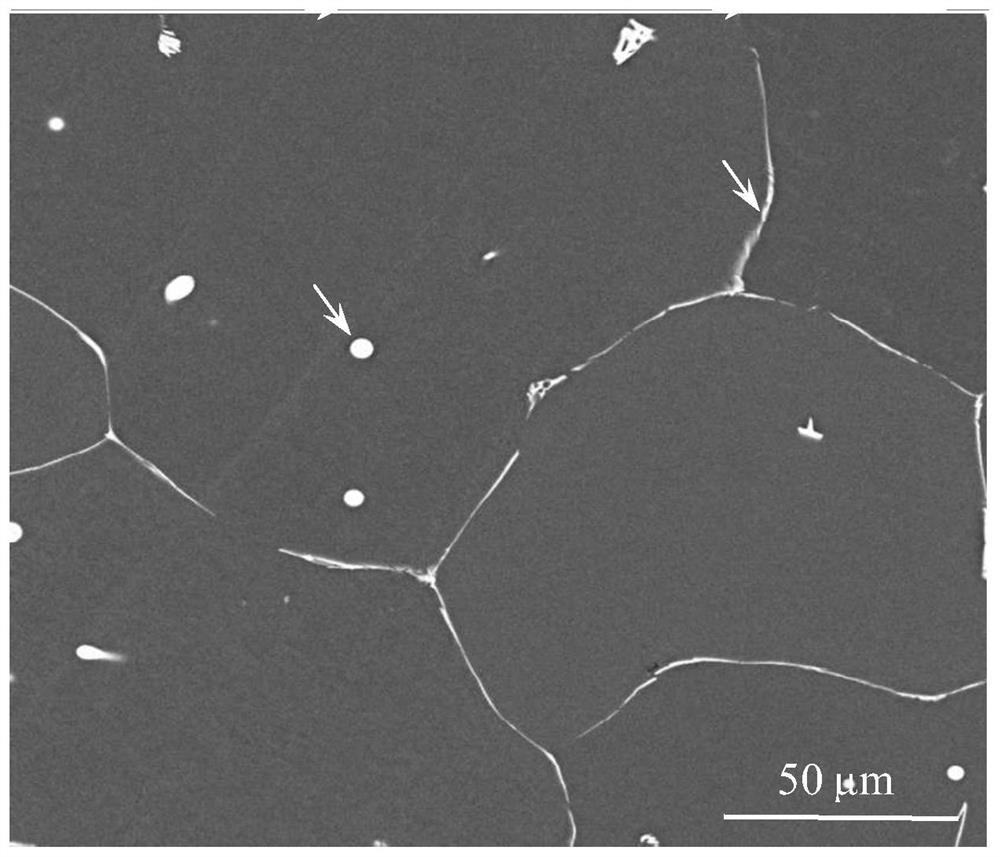

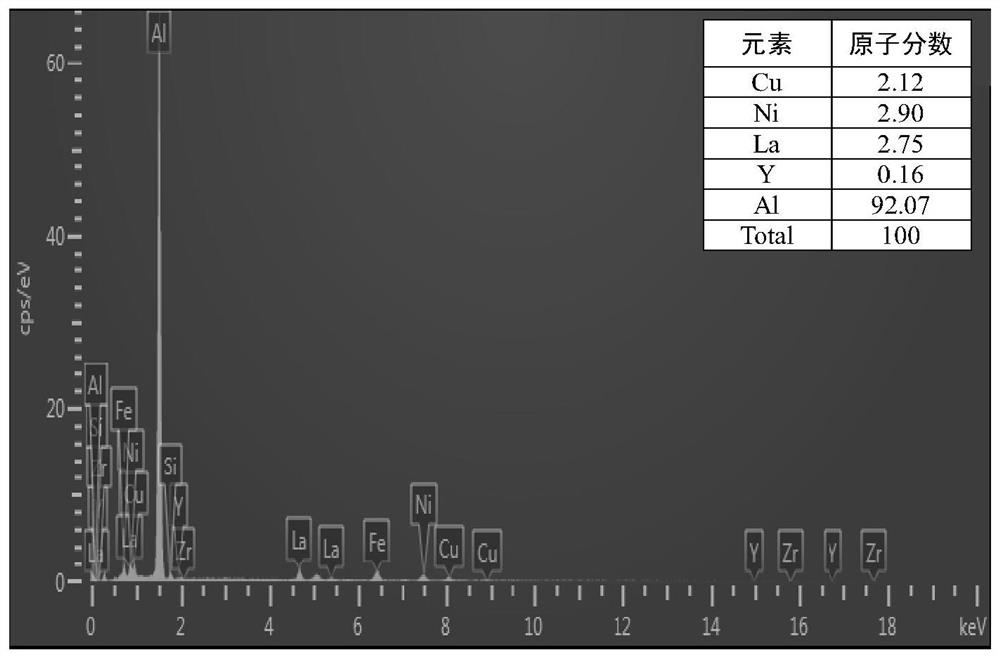

Image

Examples

Embodiment Construction

[0044] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail in conjunction with specific embodiments.

[0045] In the examples and comparative examples of the present invention, industrial pure aluminum ingots are used as raw materials, Zr, Cu, Ni, La, and Y elements are added in the form of master alloys, and the melting temperature is controlled to be 750°C. Stirring, refining, rapid component analysis in front of the furnace, and adjust to the composition ratio described in Table 1 according to the analysis results, wherein the content of impurity element Si is less than or equal to 0.05%, and the total content of Ti, V, Cr, and Mn impurity elements is less than 0.01wt.%. , Al is the balance.

[0046] Table 1 Alloy element composition distribution table (wt%)

[0047]

[0048]

[0049] After the chemical composition is stabilized, continuous casting is carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com