High-brightness colored light reflecting product

A colored light and high-brightness technology, which is applied in the field of high-brightness colored light reflective products, can solve the problems of general light intensity effect, non-transparent reflective film surface, and inconspicuous colored light color effect, etc., to achieve market competitiveness and guarantee The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

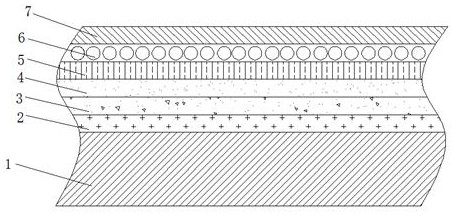

Image

Examples

Embodiment 1

[0033] A preparation process for high-brightness colored light-reflective fabrics, comprising the steps of:

[0034] The first major step is to prepare the plant membrane;

[0035] a. First, the PET film is coated with glue by a dimple coater, and then heated and compounded with the metallocene PE film to obtain a prefabricated film, and then the prefabricated film is trimmed for use;

[0036] b. Next, plant glass microspheres on the surface of the prefabricated film after trimming, and the glass microspheres have a refractive index of 1.90~1.93 and a size of 300~400 mesh.

[0037] c. Send the prefabricated film after planting glass beads into the oven, and after passing through a drying tunnel, apply a layer of interference color transparent protective layer glue on the surface of the glass bead layer, and then apply it on the surface of the interference color protective layer Apply a layer of transparent coloring material with pearlescent powder, put it into the incubator a...

Embodiment 2

[0044] A preparation process for high-brightness colored light-reflective leather, comprising the steps of:

[0045] The first major step is to prepare the plant membrane;

[0046] a. First, the PET film is coated with glue by a dimple coater, and then heated and compounded with the metallocene PE film to obtain a prefabricated film, and then the prefabricated film is trimmed for use;

[0047]b. Next, plant glass microspheres on the surface of the prefabricated film after trimming, and the glass microspheres have a refractive index of 1.90~1.93 and a size of 300~400 mesh.

[0048] c. Send the prefabricated film after planting glass beads into the oven, and after passing through a drying tunnel, apply a layer of interference color transparent protective layer glue on the surface of the glass bead layer, and then apply it on the surface of the interference color protective layer Apply a layer of transparent coloring material with pearlescent powder, put it into the incubator af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap