Electric driving system, power assembly and electric automobile

A technology of electric drive system and circuit, which is applied in the field of on-board charger, electric drive system, powertrain and electric vehicle, which can solve the problems of limited adjustment ability and difficulty in realizing the potential balance of the midpoint of the busbar, so as to achieve potential balance and good regulation Ability, effect of increasing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

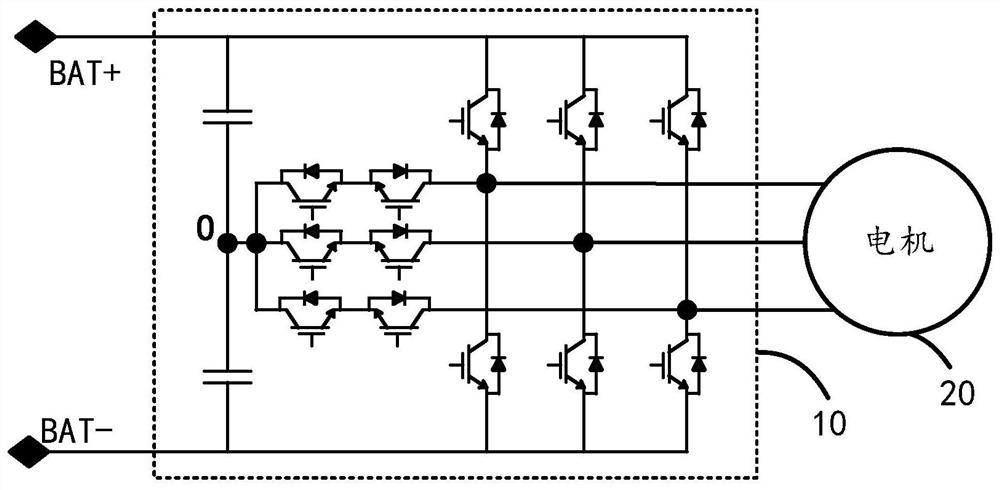

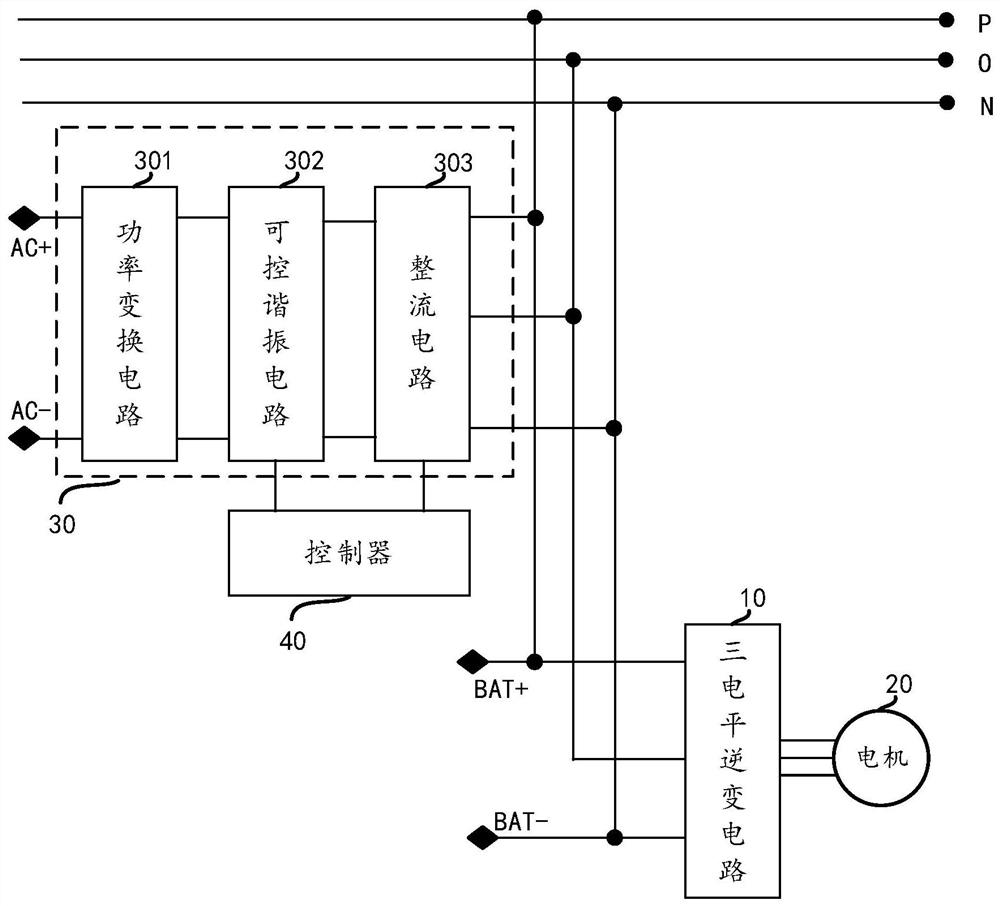

[0062] An embodiment of the present application provides an electric drive system for controlling the midpoint potential balance of a bus bar of a three-level inverter circuit, which will be described in detail below with reference to the accompanying drawings.

[0063] see image 3 , which is a schematic diagram of an electric drive system provided in an embodiment of the present application.

[0064] The electric drive system includes a bus bar, a three-level inverter circuit 10 , an on-board charger 30 and a controller 40 .

[0065] Wherein, the bus includes a positive bus (indicated by P in the figure) and a negative bus (indicated by N in the figure).

[0066] The on-board charger 30 includes a power conversion circuit 301 , a controllable resonance circuit 302 and a rectification circuit 303 .

[0067] The input end of the power conversion circuit 301 is the input end of the vehicle charger 30 , and the output end of the power conversion circuit 301 is connected to the...

Embodiment 2

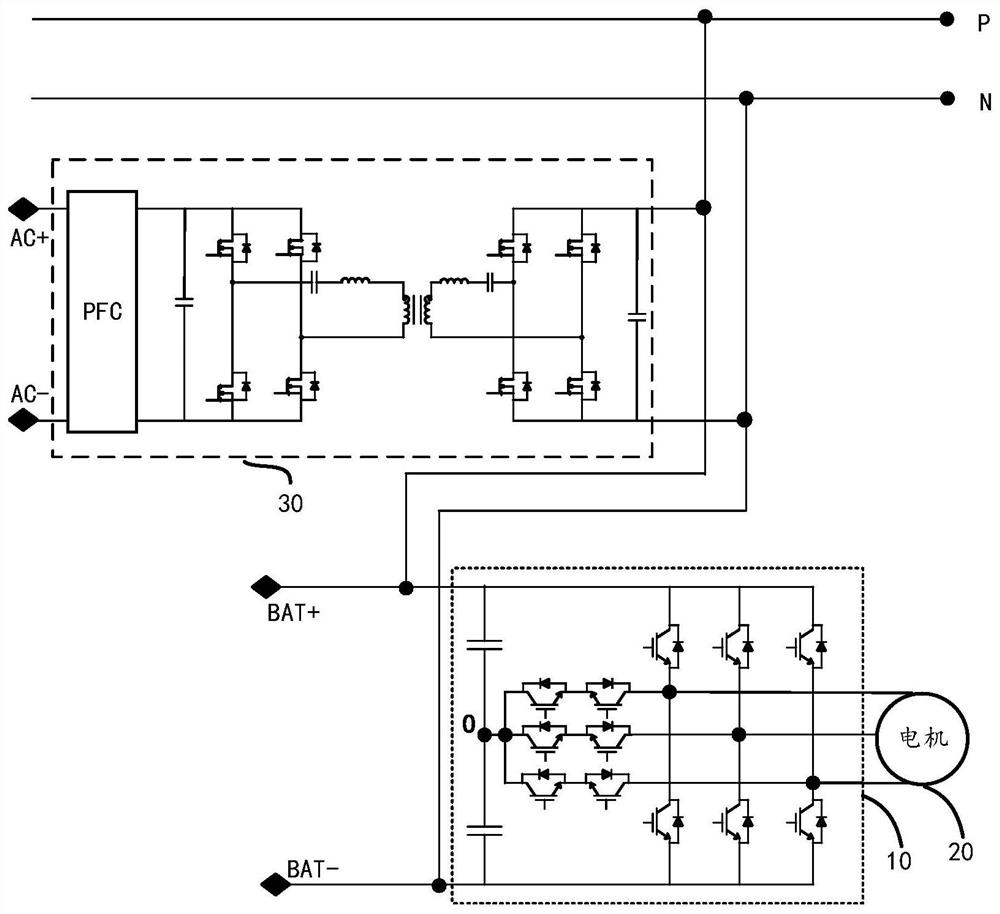

[0088] In the embodiment of the present application, the on-board charger is used as an example for illustration.

[0089] see Figure 6 , which is a schematic diagram of another electric drive system provided in the embodiment of the present application.

[0090] The vehicle charger 30 shown in the figure is a CLLC type vehicle charger, and its power conversion circuit 301 is an LLC resonant conversion circuit.

[0091] The controllable resonant circuit 302 of the on-board charger 30 includes a controllable switch S and a resonant unit. The resonant unit includes a first inductor L and a first capacitor Co connected in series.

[0092] In some other embodiments, the first inductance L may also represent the equivalent inductance of multiple inductors, and the first capacitance may also represent the equivalent capacitance of multiple capacitors.

[0093] The controllable switch S may be a controllable switch tube.

[0094] The secondary winding of the CLLC type vehicle ch...

Embodiment 3

[0116] The working principle of the electric drive will be described below in conjunction with another specific implementation manner.

[0117] see Figure 8 , which is a schematic diagram of another electric drive system provided in the embodiment of the present application.

[0118] The vehicle charger 30 shown in the figure is an LLC type vehicle charger, and its power conversion circuit 301 is an LLC resonant conversion circuit.

[0119] The controllable resonant circuit 302 of the on-board charger 30 includes a first controllable switch S1 , a second controllable unit S2 and a resonant unit. The resonant unit includes a first inductor L and a first capacitor Co connected in series.

[0120] The first controllable switch S1 and the second controllable switch S2 may be controllable switch tubes.

[0121] The first output terminal of the power conversion circuit 301 is connected to the first terminal of the first controllable switch S1 and the first input terminal of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com