Ultrathin nanosheet material with coexisting crystal and amorphous interfaces and water electrolysis application of ultrathin nanosheet material

A nanosheet and amorphous technology, applied in the field of preparation and ultrathin nanosheet materials, can solve the problems of high energy consumption, damage to the metal center coordination of MOFs, and difficulty in electrocatalysis of MOFs, so as to promote the conversion process and promote full exposure. and the effect of fast charge/electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

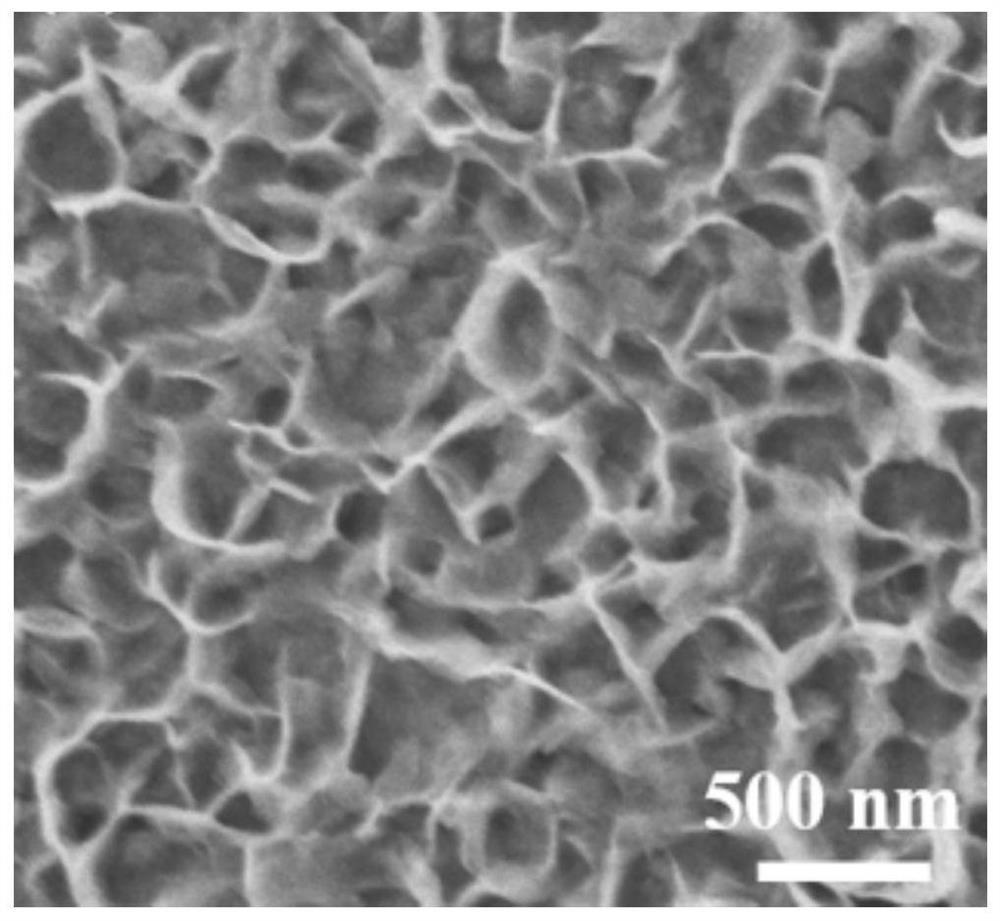

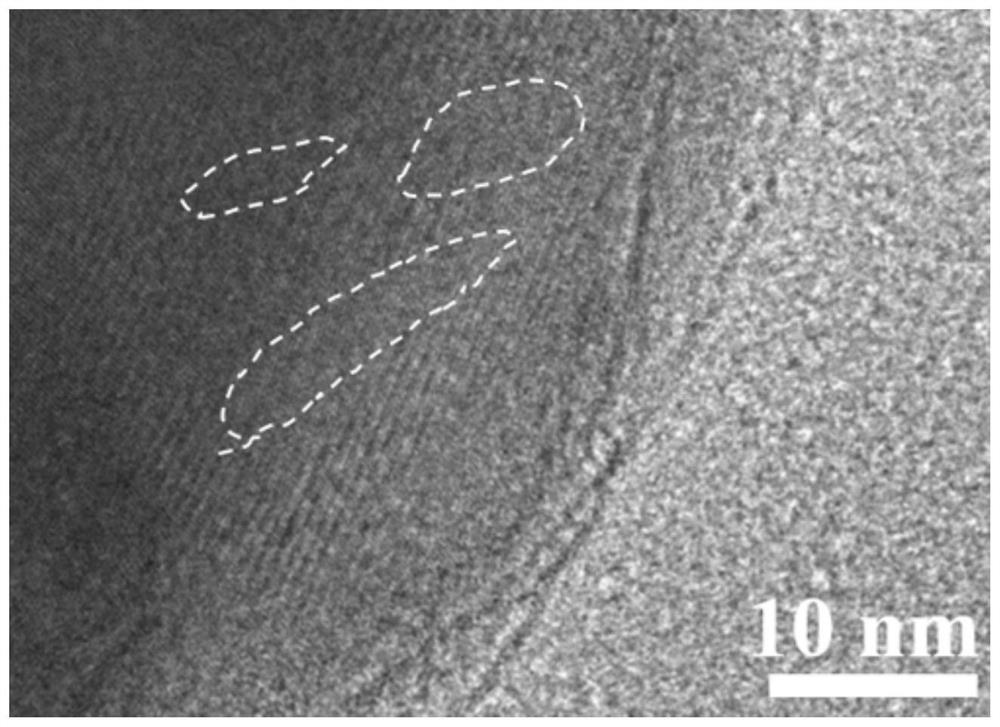

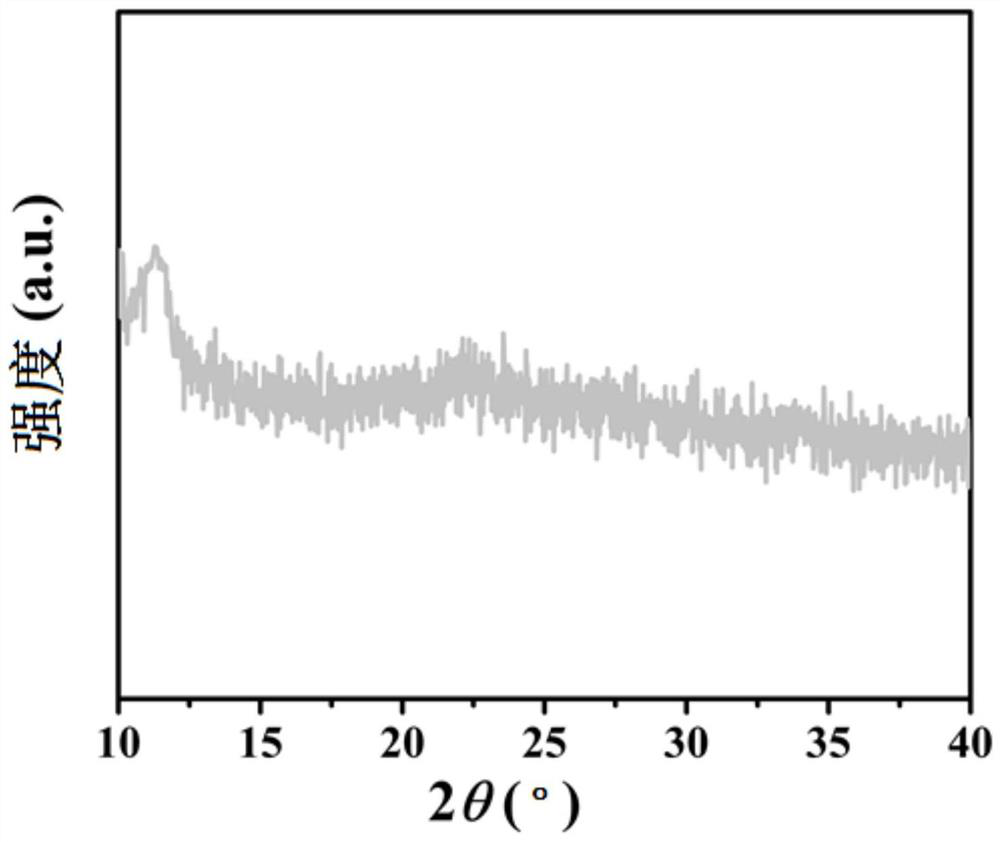

[0038]The preparation process of Ni-ZIF / Ni-B-4@NF electrocatalyst is as follows:

[0039] 1) Cut out nickel foam (1cm×2cm), use acetone, ethanol, and deionized water to sonicate for 5 minutes, and use it as a substrate after drying in a 60°C oven.

[0040] 2) 10mL Ni(NO 3 ) 2 ·6H 2 O (580 mg) methanol solution was added to 20 mL dimethylimidazole (660 mg) methanol solution, and the obtained solution was sonicated for 1 minute until the solution was mixed uniformly. The solution was transferred to a 50mL reactor, put into the treated foamed nickel substrate, and reacted hydrothermally at 180°C for 6 hours. Finally, the precursor obtained by the reaction was rinsed with deionized water, and dried in an oven at 60° C. for 12 hours.

[0041] 3) Take 1.8915g of sodium borohydride and dissolve it in 50mL of deionized water, put it into the precursor nickel foam, and control the boronation time to 4 hours. After the reaction, the product was taken out, rinsed with deionized wate...

Embodiment 2

[0053] In this example, the boronization time was controlled to be 2 hours, and the rest was the same as in Example 1 to prepare Ni-ZIF / Ni-B-2@NF electrocatalyst.

Embodiment 3

[0055] In this example, the boronization time was controlled to be 9 hours, and the rest was the same as in Example 1 to prepare Ni-ZIF / Ni-B-9@NF electrocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com