Treatment method of waste aluminum oxide in anthraquinone process hydrogen peroxide production process

An anthraquinone method hydrogen peroxide, production process technology, applied in the field of waste alumina solid waste treatment, can solve the problems of large energy consumption, high cost, generation of hazardous waste and the like, and achieves the effect of wide selection range and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

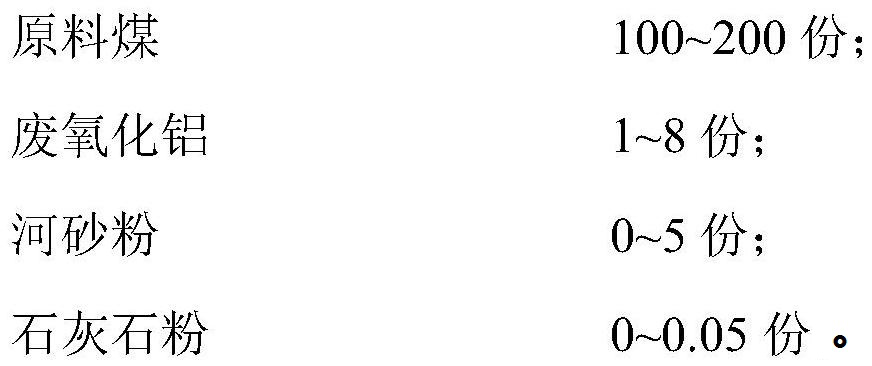

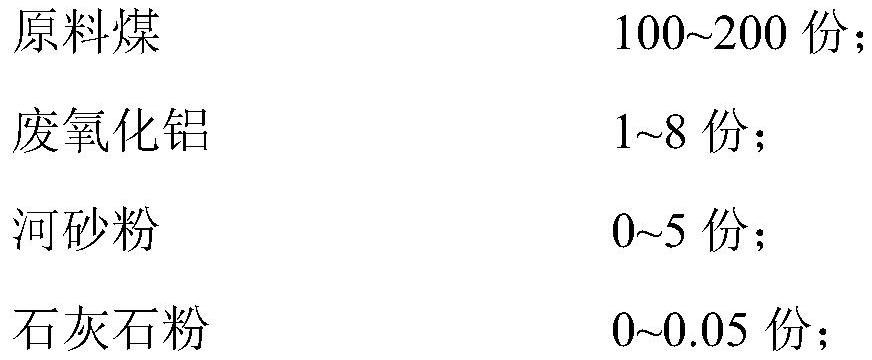

Method used

Image

Examples

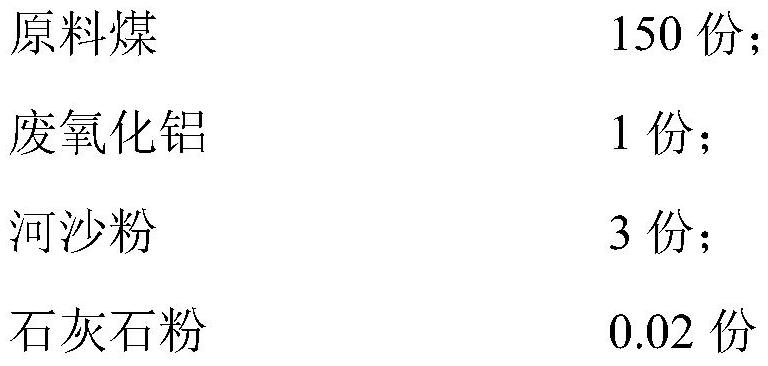

Embodiment 1

[0020] (1) The waste alumina pellets from the hydrogen peroxide production process unit are sent into the waste alumina silo;

[0021] (2) The adjustable feeding device (vibration feeder, belt scale, rotor scale) continuously, uniformly and quantitatively sends the alumina pellets to the center of the grinding disc of the mill, and evenly spreads them to the grinding roller and grinding disc under the action of centrifugal force In the crushing area between the grinding rollers, the materials are quickly crushed by the strong roller pressure and grinding force of the grinding rollers. The crushed materials form a material bed of a certain thickness between the grinding rollers and the grinding disc for intergranular grinding; the materials reaching a certain fineness are produced by The strong airflow generated by the air induction system is brought to the upper classification area integrated with the mill for classification and extraction. The qualified fine powder enters the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com