Glycosylase biosensor based on carboxylated nano-zinc oxide and preparation method and application thereof

A nano-zinc oxide, biosensor technology, applied in instruments, scientific instruments, electrochemical variables of materials, etc., can solve the problems of long detection time, low selectivity, complex instruments, etc., achieve low detection limit, simple preparation, anti-interference powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation of nano zinc oxide used in the present invention is as follows:

[0046] (1) Add 1mol / L (NH 4 ) 2 CO 3 The solution was added dropwise to 1mol / L ZnSO 4 In the solution, stir while dropping until pH = 8, then heat and react in a water bath at 60°C for 1 h;

[0047] (2) After the reaction is completed, repeatedly wash and filter the reaction solution with distilled water until no SO is detected in the filtrate. 4 2- So far (with BaCl 2 test);

[0048] (3) Dry the obtained white product in a vacuum oven at 110°C for 10 hours to obtain a zinc oxide precursor;

[0049] (4) Calcining the obtained zinc oxide precursor in a high-temperature tube furnace at 500° C. for 2 hours, and then the nano-zinc oxide material can be prepared.

Embodiment 1

[0051] A method for preparing a glycerase biosensor based on carboxylated nano zinc oxide, comprising the following steps:

[0052] (1) Weigh 2.5g of nano-zinc oxide in a conical flask, add 60g of distilled water for ultrasonic dispersion for 4 hours; In the three-necked flask, add 1.25g vinyltriethoxysilane subsequently, and heat the reaction in a water bath at a temperature of 85°C for 2h; Dissolve 0.73g of ammonium persulfate and 0.18g of sodium bisulfite in distilled water), and continue to react in a water bath at 85°C for 3.5h; Carboxylated nano zinc oxide material.

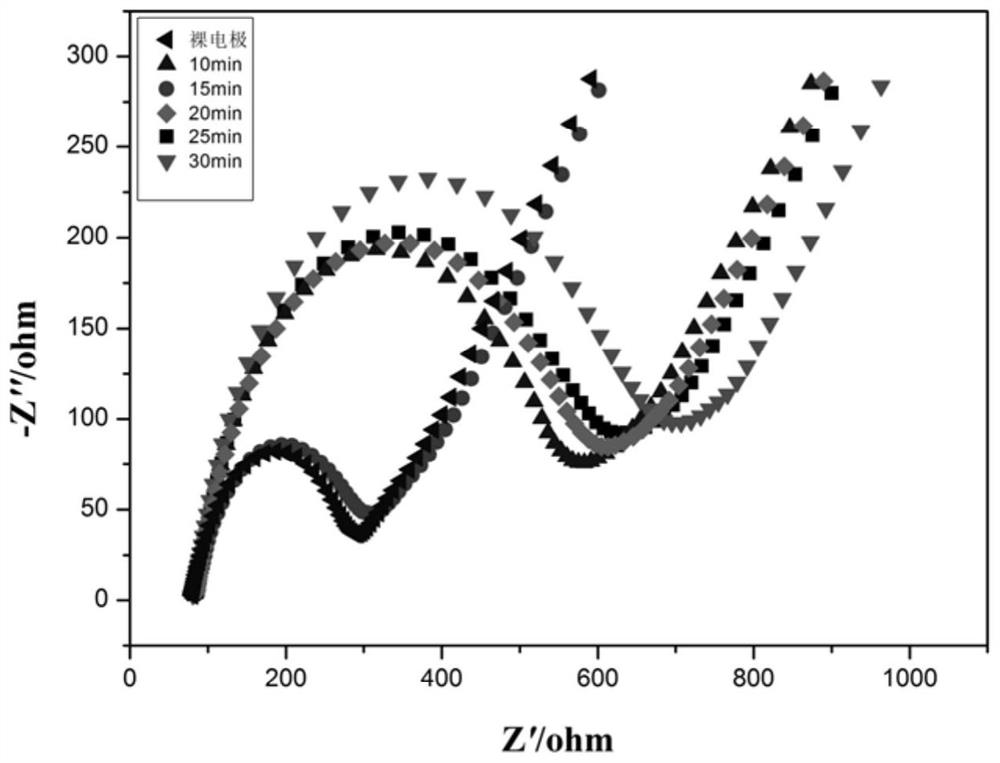

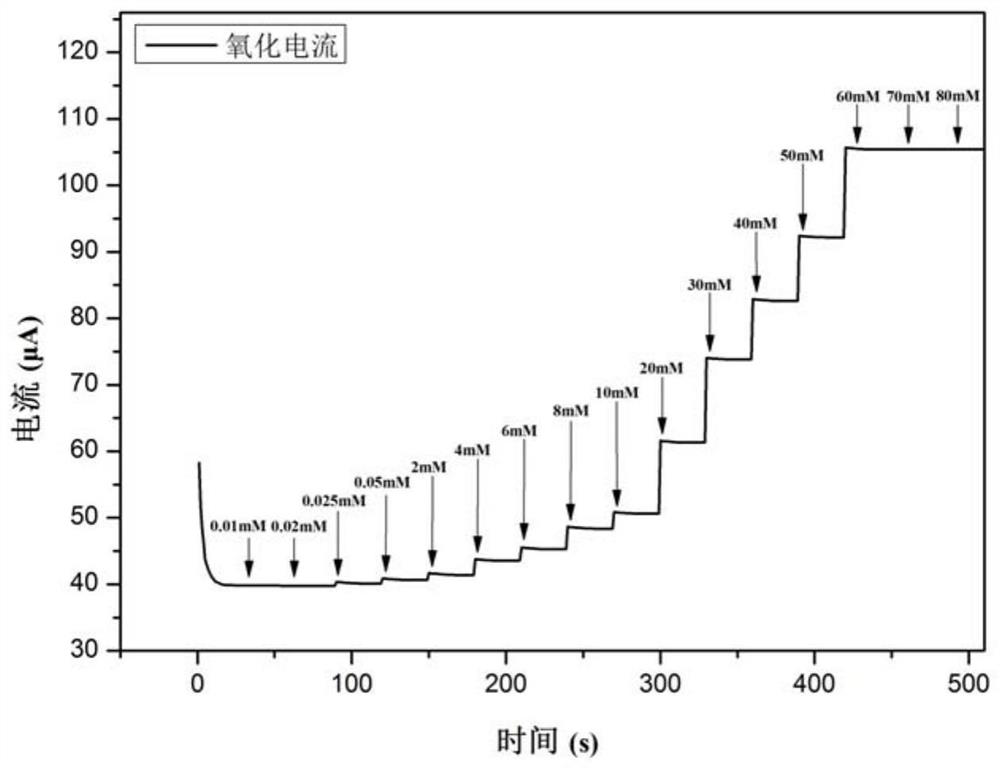

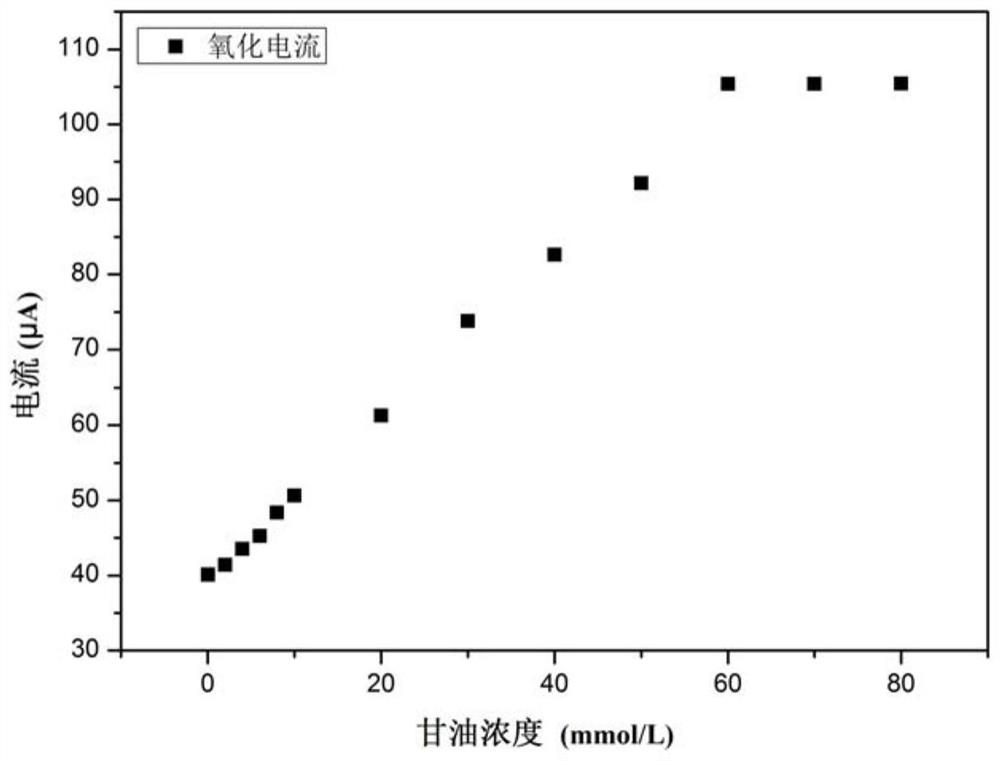

[0053] (2) A gold electrode with a diameter of 3 mm is sequentially covered with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder was polished to a mirror surface, rinsed with distilled water; then ultrasonically cleaned in absolute ethanol and distilled water for 2 minutes, taken out and washed with distilled water; 2 SO 4 In the solution, scan to stability by cyclic voltammetry at -0.1 ~ 1.2...

Embodiment 2

[0062] A method for preparing a glycerase biosensor based on carboxylated nano zinc oxide, comprising the following steps:

[0063] (1) Weigh 2.5g of nano-zinc oxide in a conical flask, add 60g of distilled water for ultrasonic dispersion for 4 hours; In the three-necked flask, add 1.25g vinyltriethoxysilane subsequently, and heat the reaction in a water bath at a temperature of 85°C for 2h; Dissolve 0.73g of ammonium persulfate and 0.18g of sodium bisulfite in distilled water), and continue to react in a water bath at 85°C for 3.5h; Carboxylated nano zinc oxide material.

[0064] (2) A gold electrode with a diameter of 3 mm is sequentially covered with Al with a diameter of 0.3 μm and 0.05 μm 2 o 3 The powder is polished to a mirror surface, rinsed with distilled water; then ultrasonically cleaned in absolute ethanol and distilled water for 2 minutes, taken out and washed with distilled water; then placed in 10 mL of 1mol / L H 2 SO 4 In the solution, scan to stability by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com