Inclusion type low-smoke antimony-free flame retardant based on cucurbituril and application of inclusion type low-smoke antimony-free flame retardant

A flame retardant and nitrogen-based flame retardant technology, which is applied in the synthesis and application of flame retardant materials, can solve the problems of reducing flame retardant efficiency and lack of universality, and achieves excellent flame retardant effect, good flame retardant efficiency, Synergistic effect with high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

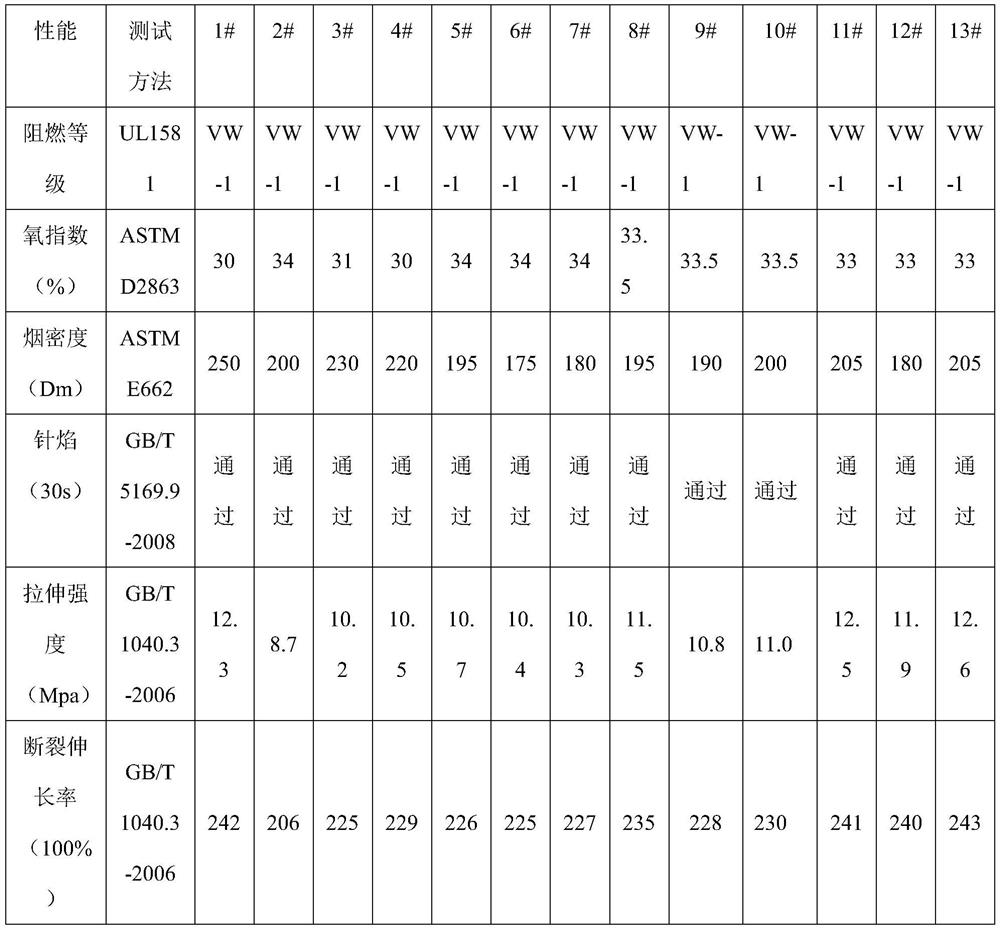

Examples

Embodiment 1

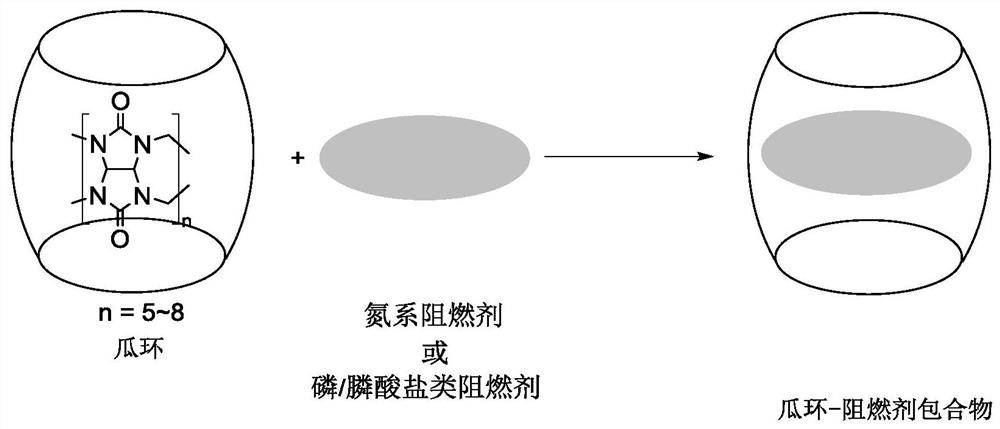

[0031] A preparation method based on a melon inclusion type low-smoke antimony-free flame retardant, comprising the steps of:

[0032] (1) Dissolve the five-membered melon rings in concentrated hydrochloric acid, the mass of which is 4 times that of the five-membered melon rings, and raise the temperature to 80°C to completely dissolve the melon rings. Add ammonium polyphosphate according to the molar ratio of cucurbit ring to ammonium polyphosphate is 1.0:0.5, and stir until completely dissolved. Continue to react for 5h and cool to room temperature. Take out the solution and place it in a beaker, add a large amount of ethanol to stir, and precipitate out. The precipitate was obtained by filtration, washed with distilled water, and dried in a vacuum oven at 80° C. to obtain a white cucurbit-flame retardant clathrate solid.

[0033](2) Put 20g MEL, 45g melon ring-flame retardant clathrate solid, 25g metal magnesium hydroxide, and 25g zinc borate into the high-speed mixer in ...

Embodiment 2

[0035] A preparation method based on a melon inclusion type low-smoke antimony-free flame retardant, comprising the steps of:

[0036] (1) Dissolve the six-membered melon rings in concentrated hydrochloric acid, the mass of which is 5 times that of the six-membered melon rings, and raise the temperature to 90°C, and the melon rings will all dissolve. Add melamine phosphate according to the molar ratio of cucurbit ring to melamine phosphate is 1.0:0.8, and stir until completely dissolved. The reaction was continued for 3h and cooled to room temperature. Take out the solution and place it in a beaker, add a large amount of ethanol to stir, and precipitate out. The precipitate was obtained by filtration, washed with distilled water, and dried in a vacuum oven at 80° C. to obtain a white cucurbit-flame retardant clathrate solid.

[0037] (2) Put 30g MCA, 40g melon ring-flame retardant clathrate solid, 20g metal aluminum hydroxide, and 20g zinc borate into the high-speed mixer in...

Embodiment 3

[0047] A preparation method based on a melon inclusion type low-smoke antimony-free flame retardant, comprising the steps of:

[0048] (1) Dissolve the seven-membered melon rings in concentrated hydrochloric acid, the mass of which is 6 times that of the seven-membered melon rings, and raise the temperature to 100°C to completely dissolve the melon rings. According to the molar ratio of cucurbit ring and diammonium hydrogen phosphate is 1.0:1.0, add diammonium hydrogen phosphate and stir until completely dissolved. The reaction was continued for 4h and cooled to room temperature. Take out the solution and place it in a beaker, add a large amount of ethanol to stir, and precipitate out. The precipitate was obtained by filtration, washed with distilled water, and dried in a vacuum oven at 80° C. to obtain a white cucurbit-flame retardant clathrate solid.

[0049] (2) Put 40g MEL, 35g melon ring-flame retardant clathrate solid, 15g metal calcium hydroxide, and 15g zinc borate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com