High-dielectric graphene-based elastomer composite material and preparation method thereof

A composite material and graphene-based technology, applied in the field of dielectric materials, can solve the problems of increased dielectric loss of elastomers, affecting safety, and reduced breakdown strength, so as to reduce dielectric loss, improve breakdown strength, and reduce The effect of the modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

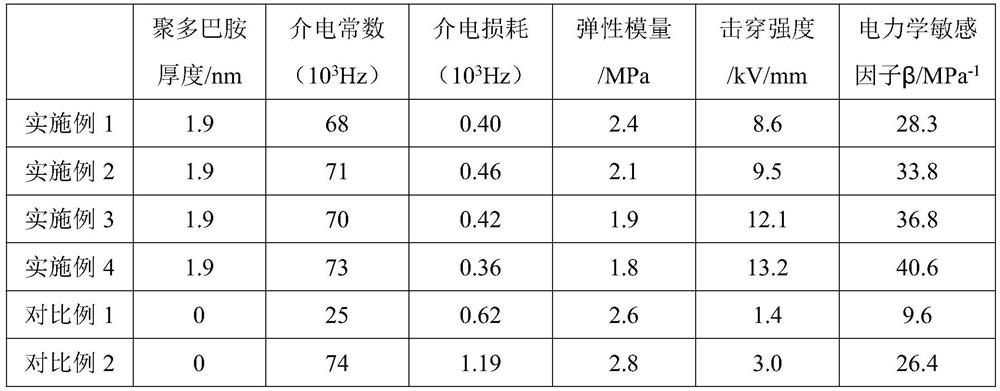

Examples

preparation example Construction

[0029] Preferably, the preparation method of described graphene dielectric filler comprises the following steps:

[0030] S1. Weigh 1g of non-ionic surfactant and dissolve it in deionized water to prepare a solution with a concentration of 1g / L to obtain solution A; weigh 0.32g of graphene oxide nanosheets and ultrasonically disperse them in 120ml of 1mol / L hydrochloric acid solution to obtain solution B; solution B was added to solution A, then 10ml of 30% hydrogen peroxide solution and 2.5g of trishydroxymethylaminomethane were added, and the mixed solution was heated to 35-40°C, Stir and mix for 10-30min to obtain solution C;

[0031] S2, take by weighing 0.38g of dopamine hydrochloride, join in the described solution C, and fully dissolve, continue to stir for 30-60min, obtain solution D; Take by weighing 3g of ammonium persulfate and prepare the aqueous solution of 0.1mol / L, and gradually Add dropwise to the solution D at a rate of 5-6ml / min. After the dropwise addition,...

Embodiment 1

[0046] A high-dielectric graphene-based elastomer composite material, comprising an elastic matrix and a graphene dielectric filler dispersed in the elastic matrix, the graphene dielectric filler being a graphene oxide nanosheet of porous polydopamine loaded on the surface , wherein, the mass ratio of the graphene dielectric filler to the elastic matrix is 1.1:100; the elastic matrix is butyl acrylate elastomer;

[0047] The preparation method of described graphene dielectric filler comprises the following steps:

[0048] S1. Weigh 1g of P123 (EO 20 PO 70 EO 20 , Ma=5800) was dissolved in deionized water and prepared as a solution with a concentration of 1g / L to obtain solution A; 0.32g of graphene oxide nanosheets were weighed and ultrasonically dispersed in 120ml of 1mol / L hydrochloric acid solution to obtain a solution B: Add solution B to solution A, then add 10ml of 30% hydrogen peroxide solution and 2.5g of trishydroxymethylaminomethane, heat up the mixed solution...

Embodiment 2

[0054] Same as Example 1, the mass ratio of the graphene dielectric filler to the elastic matrix is 0.5:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com