Method for preparing vitamin A palmitate by supercritical method

A technology of palmitate and methyl palmitate, applied in the field of preparation of VA palmitate, can solve the problems of long production cycle of VA palmitate, cumbersome process operation steps, low conversion rate and the like, and improve the transesterification reaction rate. , the effect of improving the reaction rate and conversion rate, and reducing the mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

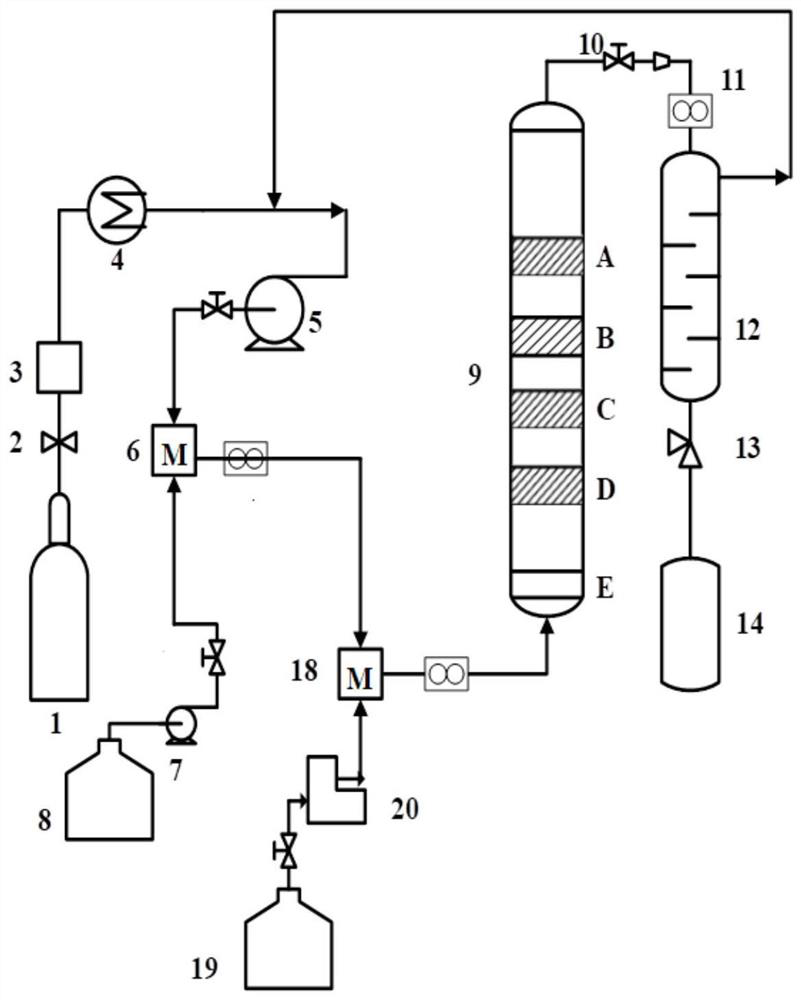

[0040] Such as figure 1 As shown, 5730 gVa alcohol (20 mol) and 6480 g of palmitate (24 mol) were placed in the raw material can be selected from 1: 1.2 molar ratio of the raw material Va alcohol and palmitate. Open the methanol pressure reducing valve and methanol gas tank pressure reducing valve, a mixture of volumetric flow rate of 12 l / min supercritical methanol and trifluorometise (supercritical methanol and trifluorometise bromochiome is 20: 1) In the mixer, the mixture temperature was 239.1 ° C, and the pressure was 8.1 MPa. Further, the formulated raw material liquid was mixed by a volumetric flow of 60 ml / min and the supercritical mixture was transferred to the reactor, and the temperature was 239.1 ° C, the pressure was 8.1 MPa, and the reactor was filled with a quantity of non-metallic glass springs. It is an object to increase the liquid contact area, strengthen the mass transfer, and the glass spring fill is 5 g, the filler is 0.5 ml. The reaction process is stab...

Embodiment 2

[0042] Such as figure 1 As shown, 5270 gVa alcohol (20 mol) and 5940 g of palmitate (22 mol) were placed in the raw material tank according to the raw material Va alcohol and the palmitate molar ratio of 1: 1.1. Open the methanol pressure reducing valve and methanol gas tank pressure reducing valve, a mixture of volumetric flow rate of 13 l / min supercritical methanol and trifluorometise (supercritical methanol and trifluorometheramethiometry) is 25: 1). In the mixer, the mixed gas temperature was 245 ° C, and the pressure was 8.93 MPa. The formulated raw material liquid is delivered to the reactor after mixing by volume flow of 78 ml / min and supercritical methanol, and the temperature is 245 ° C, the pressure is 7.8 MPa, and the glass spring is filled with a glass spring fill amount of 4.5 g, and the filler volume is 3ml. . The reaction process is stabilized by the back pressure valve. After the reaction is completely (sampling at intervals, the content is stabilized to the r...

Embodiment 3

[0044] Such as figure 1 As shown, 2860 gVa alcohol (10 mol) and 3510 g of palmitate (13 mol) were added to the raw material can be measured according to the raw material Va alcohol and the palmitate molar ratio of 1: 1.3. Open the methanol pressure reducing valve and methanol gas tank pressure reducing valve, a mixture of volumetric flow rate of 14 l / min supercritical methanol and trifluorometise (supercritical methanol and trifluorometiocene bromochiome is 30: 1) In the mixer, the mixture temperature was 250 ° C, and the pressure was 9.67 MPa. The formulation mixed raw material liquid is mixed with a volumetric flow of 98 ml / min and the supercritical mixture is transferred to the reactor, and the temperature is 250 ° C, the pressure is 9.67 MPa, and the glass spring is filled with 3.5 g, and the filler volume is 2ml. The reaction process is stabilized by the back pressure valve. After the reaction is completely (sampling at intervals, the content is stabilized to the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com