Method for extracting main egg yolk protein of sea cucumber body walls by three-step precipitation

A technology of egg yolk protein and sea cucumber, applied in the field of protein extraction, can solve the problems of unsuitability for industrialized mass production, low purity of egg yolk protein, low extraction efficiency, etc., and achieves the effects of low cost, increased protein precipitation rate, and improved extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1) sea cucumber body wall pretreatment: fresh sea cucumbers are dissected to remove body cavity contents, washed and drained, and crushed by a homogenizer to obtain sea cucumber mud;

[0036] Step 2) Crude protein extraction: mix the sea cucumber mud obtained in step (1) with PBS buffer solution (pH=7.4) at a mass volume ratio of 1:5g / mL, extract at 4°C for 18 hours, and then centrifuge. The protein supernatant is the protein bold liquid, this process is repeated 3 times, and the supernatants are combined;

[0037] Step 3) Concentrate the mixed precipitation of trichloroacetic acid and acetone: Concentrate the mixed supernatant obtained in step 2) at 60°C to 1 / 4 of the original volume, and add the obtained concentrated solution while stirring to a final concentration of 10 % TCA + 1 times the volume of acetone as a precipitation reagent, let stand at 4°C for 3 hours, collect the precipitate after centrifugation, repeat this process twice, and combine the precipitat...

Embodiment 2

[0049] Change the precipitation reagent in step 3) to verify its precipitation effect. Precipitation reagents were adding trichloroacetic acid (TCA) to a final concentration of 10%, 10% TCA+1 volume of acetone, adding 1M hydrochloric acid to adjust the pH to 3.7, adding 1M hydrochloric acid to adjust the pH to 3.7+1 volume of acetone, and 2 times volume of acetone.

[0050] Comparing the effects of choosing different precipitants on crude protein, observing the precipitated protein after centrifugation, after adding 2 times the volume of acetone alone, the protein precipitated the largest amount, but when adding the final concentration of 10% TCA + 1 times the volume of acetone as When the precipitating agent is used, the precipitated protein is whiter, which shows that 10% TCA + 1 volume of acetone can cooperate to precipitate, so that the precipitated protein content is high.

[0051] In addition, 20% TCA was added during the experiment, and the amount of precipitation was ...

Embodiment 3

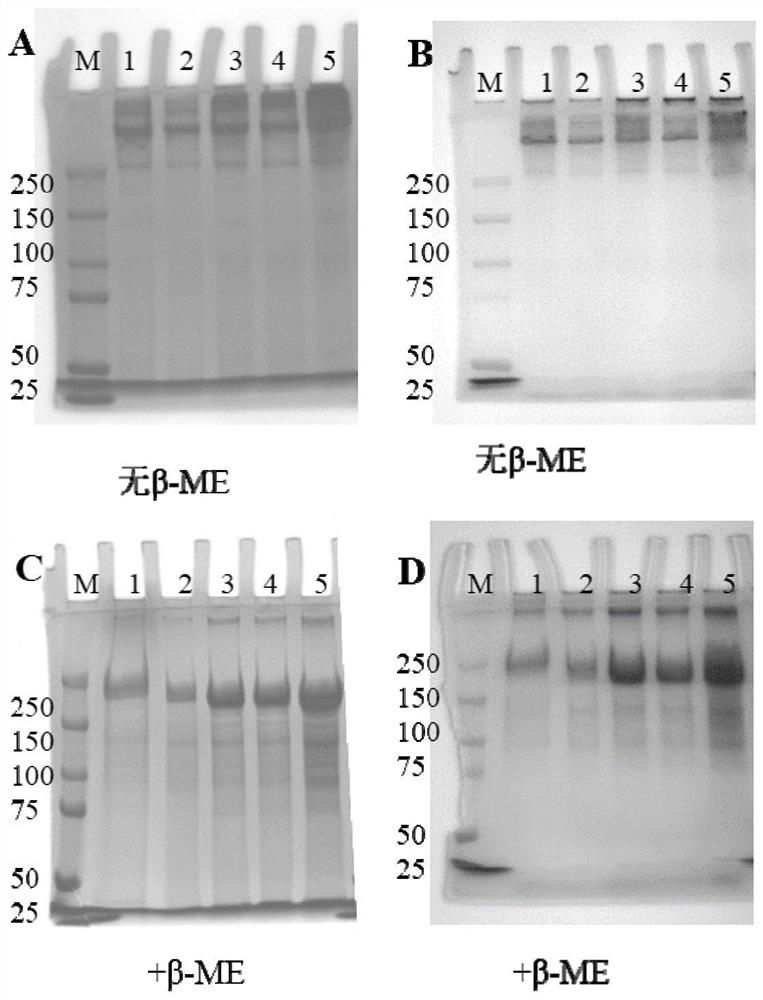

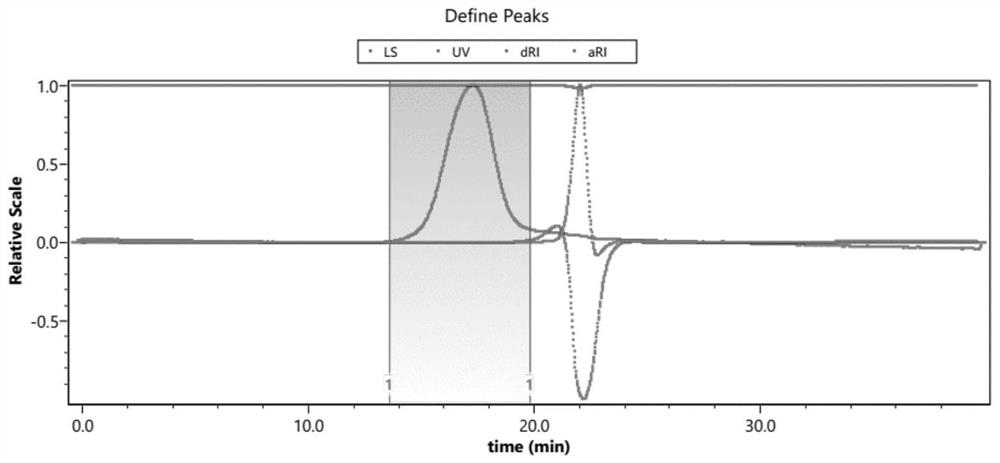

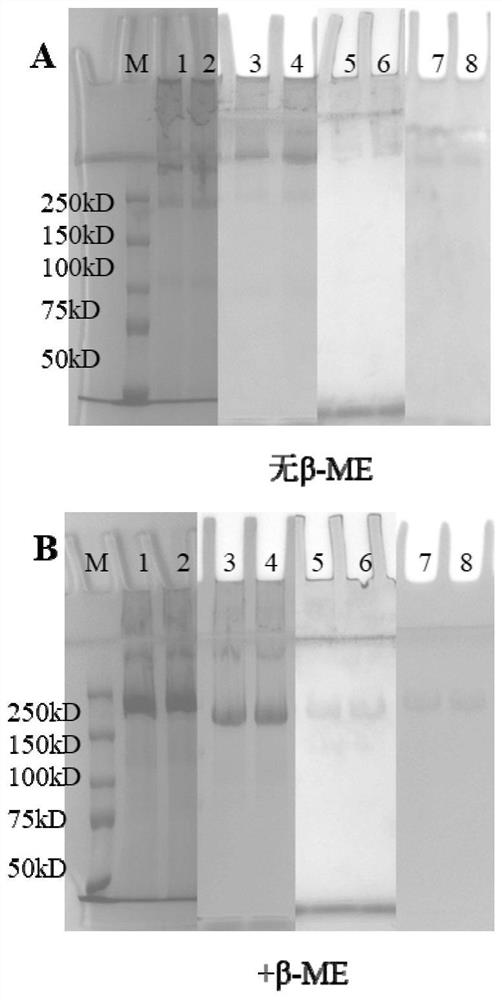

[0053] Change the final concentration of ammonium sulfate in step 5) to be 0, 20%, 40%, 60%, 80%, 100% respectively. By comparing the effect of different concentration gradients of ammonium sulfate on the protein precipitation results ( Figure 5 and Figure 6 ), found that with the increase of ammonium sulfate amount, the amount of protein precipitation increased gradually, when the mass volume ratio of ammonium sulfate and water was 0.4, the protein content of precipitation was more, and the bands were cleaner without impurity pollution. At the same time, considering the difficulty of the next step of dialysis desalination, the final concentration of ammonium sulfate and ammonium sulfate is selected to be 30-40% in this method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com