Corbicula fluminea-flavored hot pot dipping sauce and preparation method thereof

A hot pot dipping sauce and river clam technology, applied in freezing/cooling preservation of meat/fish, food science, etc., can solve the problems such as no river fresh flavor hot pot dipping sauce report, achieve good economic benefits and application prospects, and cheap raw materials Easy to obtain and improve thawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

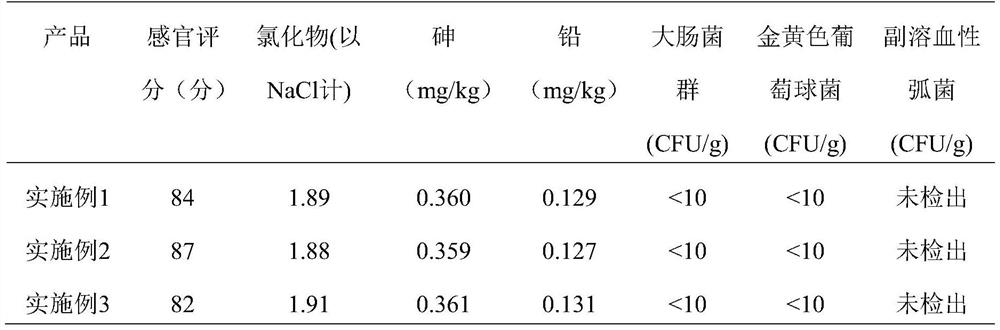

Embodiment 1

[0027] Step 1, selection and processing of raw and auxiliary materials: thaw the frozen boiled clam meat by ultrasonic waves, and drain the water; beat 5% bean paste and 5% fermented bean curd with a cooking machine respectively according to the mass percentage to obtain bean paste and fermented bean curd for use; put them in an iron pot Add 2 liters of water, add 0.3% pepper, 0.1% nutmeg, 0.25% cinnamon, 0.01% bay leaf, 0.04% fennel, 0.1% grass fruit, 0.1% star anise, 0.85% ginger, 1% green onion according to the mass percentage, and put it on high heat After boiling, turn off the heat, cover the lid and let it cool down, filter to obtain the raw material water; mix 20% of the clam meat with 45% of the raw material water according to the mass percentage, and beat it with a cooking machine to get the clam pulp, which is set aside; Step 2, blending Cooking: add soybean oil to the iron pot, heat to 130°C, add the ready-to-use bean paste and fermented bean curd obtained in step 1 ...

Embodiment 2

[0031] Step 1, selection and processing of raw and auxiliary materials: thaw frozen boiled clam meat by ultrasonic waves, and drain water; beat 10% bean paste and 7.5% fermented bean curd with a cooking machine respectively according to the mass percentage to obtain bean bean paste and fermented bean curd; put them in an iron pot Add 2 liters of water, add 0.3% pepper, 0.1% nutmeg, 0.25% cinnamon, 0.01% bay leaf, 0.04% fennel, 0.1% grass fruit, 0.1% star anise, 0.85% ginger, 1% green onion according to the mass percentage, and put it on high heat After boiling, turn off the heat, cover and cool, filter to obtain raw water; mix 25% of clam meat with 50% of raw water according to the mass percentage, and beat with a cooking machine to obtain clam pulp, which is set aside;

[0032] Step 2, blending and boiling: add rapeseed oil to the iron pot, heat to 160°C, add the ready-to-use bean paste and fermented bean curd obtained in step 1 into the iron pot, stir-fry until red oil is obt...

Embodiment 3

[0036]Step 1, selection and processing of raw and auxiliary materials: thaw the frozen boiled clam meat by ultrasonic waves, and drain the water; beat 15% of bean paste and 10% of fermented bean curd with a cooking machine respectively according to the mass percentage to obtain bean paste and fermented bean curd; Add 2 liters of water, add 0.3% pepper, 0.1% nutmeg, 0.25% cinnamon, 0.01% bay leaf, 0.04% fennel, 0.1% grass fruit, 0.1% star anise, 0.85% ginger, 1% green onion according to the mass percentage, and put it on high heat After boiling, turn off the heat, cover and cool, filter to obtain raw water; mix 30% of clam meat with 55% of raw water according to the mass percentage, and beat with a cooking machine to obtain clam pulp, which is set aside;

[0037] Step 2, blending and cooking: Add peanut oil to the iron pot, heat to 150°C, add the ready-to-use bean paste and fermented bean curd obtained in Step 1 into the iron pot, stir fry until red oil is obtained, and then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com