Preparation method of ionic liquid

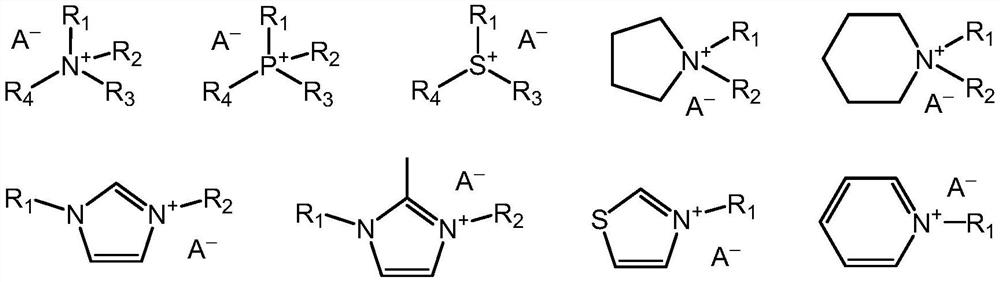

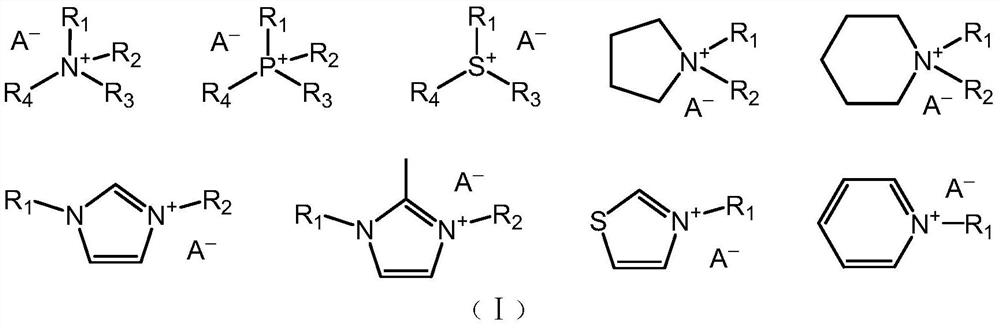

One kind of ionic liquid and another kind of technology, applied in the field of preparation of ionic liquid, can solve the problems of limited application of ionic liquid, difficult volatilization of ionic liquid, inability to refine, etc., and achieve the effect of reducing solvent residue, low equipment requirements and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing high-purity ionic liquid, comprising the following steps:

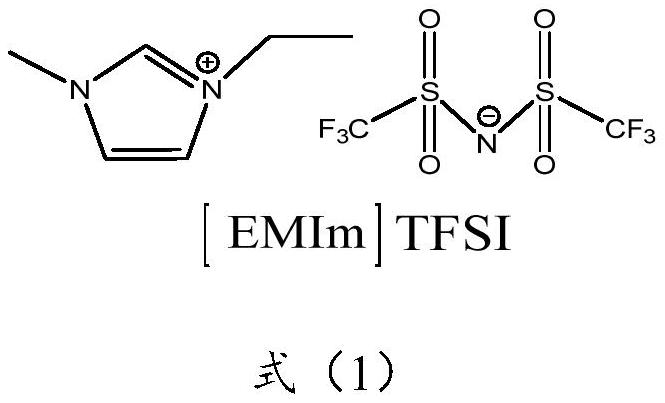

[0034] (1) The first recrystallization: by molar fraction, take 5 parts of 1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide salt [EMlm]TFSI ionic liquid crude product, 70°C Rotary steam for 4 hours, wait for the crude product to cool down to room temperature, add the recrystallization mixed organic reagent (by mass parts, 7 parts of dichloromethane and 6 parts of ethyl acetate), shake it manually, and wait for the crude product of the ionic liquid and the recrystallization reagent to fully After mixing, refrigerate in a -80°C refrigerator, let stand for 24 hours, and precipitate transparent crystals;

[0035] (2) The second recrystallization: Pour out the solvent after the first recrystallization, and place the transparent crystal obtained after recrystallization at room temperature until the crystal dissolves, and then spin evaporate at 75°C to remove the impurity in the rec...

Embodiment 2

[0039] A method for preparing high-purity ionic liquid, comprising the following steps:

[0040] (1) The first recrystallization: by molar fraction, take 7 parts of the crude product of 1-butyl-3-methylimidazolium hexafluorophosphate [BmIm]PF6 ionic liquid, rotary steam at 60°C for 4 hours, and wait for the crude product to cool down to room temperature, add the recrystallization mixed organic reagent (according to the mass parts, 7 parts of methanol and 6 parts of acetonitrile), shake it manually, and after the crude ionic liquid is fully mixed with the recrystallization reagent, put it in a -80°C refrigerator for refrigeration. After standing for 24 hours, transparent crystals were precipitated;

[0041] (2) The second recrystallization: Pour out the solvent after the first recrystallization, and place the transparent crystal obtained after recrystallization at room temperature until the crystal dissolves, and then spin evaporate at 75°C to remove the impurity in the recryst...

Embodiment 3

[0045] A method for preparing high-purity ionic liquid, comprising the following steps:

[0046] (1) The first recrystallization: In terms of molar parts, take 4 parts of 1-methyl-1-propylpyrrole bis(fluorosulfonyl)imide salt P1,3FSI crude ionic liquid, and rotary steam at 60°C for 4h , when the crude product cools down to room temperature, add recrystallization mixed organic reagent (according to mass parts, 7 parts of isopropanol and 6 parts of acetone), shake manually, after the crude product of ionic liquid and recrystallization reagent are fully mixed, put into- Refrigerate in a refrigerator at 80°C, let it stand for 24 hours, and transparent crystals will precipitate;

[0047] (2) For the second recrystallization, pour out the solvent after the first recrystallization, and place the transparent crystal obtained after recrystallization at room temperature until the crystal dissolves, and then spin evaporate at 75°C to remove the impurity during recrystallization Recrysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com